Fast powder change: unlocking the full potential of Sinterit SLS

The introduction of Rapid Finish for the Sinterit Lisa X — a PA12 Industrial material profile inspired by innovations from Sinterit Suzy — is a new step forward in making SLS 3D printing faster to deploy and easier to scale. Rapid Finish is a tuned processing profile and workflow for PA12 Industrial that focuses on improved surface quality and predictable mechanical performance while keeping the robustness companies expect from PA12.

But the story is not just about the profile itself. It’s also about the machines that make it practical. With Sinterit Lisa X and Sinterit Suzy, switching from one powder or profile to another takes only minutes, not hours. In industries where time and flexibility are everything, this ability to quickly swap powders and processing profiles can be the difference between a stalled workflow and a competitive edge.

The hidden cost of powder & profile changeovers

For many SLS 3D printing systems, changing materials or processing profiles is one of the most painful parts of the process. It’s either not possible at all or very complicated, requiring dedicated equipment, service visits, and long downtime. For service providers and manufacturers who handle multiple projects, these lost hours add up to lost opportunities. For R&D teams, slow changeovers mean slower iterations. And for educational institutions, complexity can discourage experimentation. This is where Sinterit’s design philosophy stands out.

Minutes, not hours: the Sinterit advantage

Both Lisa X and Suzy are built with powder handling and rapid workflow changes in mind. Thanks to open architecture, tool-free access to core areas, and simple maintenance points, cleaning and switching materials or processing profiles is dramatically faster — instead of planning half a day around a change, even inexperienced users can transition in under an hour, and with practice, within minutes. That speed translates directly into agility. Whether you are switching between PA12 Industrial and the PA11.5, our newest powder, or testing different engineering-grade powders, the ability to adapt instantly makes a difference.

Why this matters for different users

1. Service providers

For service bureaus and print farms, customer needs vary daily. One client may need a stiff PA12 Industrial prototype; another may request parts with a superior surface finish for final visual inspection using PA12 Smooth.

- Faster turnaround: Quick changes reduce queues and speed delivery.

- Higher utilisation: Machines print more and sit idle less.

- Customer satisfaction: Accept more diverse projects without logistics headaches.

- Result: more jobs, more clients, better margins.

2. Small-batch production

Low-volume production is a strong SLS use case. Companies producing small runs often switch powders or profiles by product line.

- Just-in-time flexibility: Adjust materials or finish level per batch.

- Cost control: Use the appropriate material for each part.

- Efficiency at scale: Keep machines running with minimal downtime.

Combining PA12 Industrial affordability with PA11 CF’s strength creates a meaningful competitive advantage.

3. R&D teams

Iteration speed is everything in R&D. Test a baseline PA12 Industrial print one day and switch to PA11 ESD for real-life validation the next — accelerating innovation.

- Faster prototyping cycles.

- Budget optimisation: allocate high-end powders where they matter most.

- Material & profile versatility: experiment without workflow bottlenecks.

Sinterit’s approach keeps R&D lean, fast, and curious.

4. Educational institutions

For universities and training centres, SLS is a powerful teaching tool — but costs and complexity can be barriers.

- Simplified workflows: Students can change powders and profiles without long procedures.

- Hands-on learning: Exposure to production-oriented profiles like Rapid Finish in a single session.

- Practical sustainability: teach material stewardship and process choices using real industrial profiles.

That empowers the next generation of engineers to explore additive manufacturing with minimal friction.

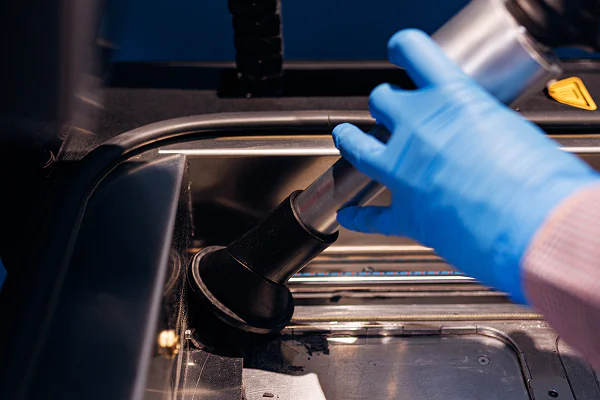

Seeing in action

Words are one thing — seeing the process is another. We’ve prepared a short video demonstration. Watch as a Sinterit Lisa X is cleaned and transitioned from a standard PA12 Industrial setup to another material in just minutes.

The ease and speed you see are exactly what Sinterit customers can expect in daily workflows.

Conclusion: time (and finish) are valuable

In additive manufacturing, innovation isn’t just about machines and powders — it’s about workflow and outcomes. Every hour saved is time for delivering products faster, testing more designs, or training more people. Whether you are a service provider, manufacturer, R&D team, or educational institution, Sinterit helps you do more with your time — and with the Rapid Finish profile for Lisa X, do more with the surface quality of your PA12 Industrial parts.

Minutes, not hours. That’s the Sinterit difference.

FAQ: Sinterit, Rapid Finish, and powder/profile changeovers

Rapid Finish is a PA12 Industrial material profile for Lisa X — a combination of tuned print parameters and workflow best-practices developed with innovations from Sinterit Suzy to improve printing speed without sacrificing PA12 performance.

Residual powder or leftover material can have different thermal behaviour; residues can affect melting and fuse with seals or other components. Proper cleaning ensures consistent results and machine longevity.

Thanks to ergonomic design and dedicated workflow tools, switching powders or profiles can be done in under 30 minutes — much faster than most competing SLS systems.

Fast changeovers reduce downtime, improve productivity, and let businesses serve diverse client needs. For R&D, they accelerate prototyping; for educators, they enable multi-material teaching.

Rapid Finish is designed to deliver improved printing speed for production-like parts printed in PA12 Industrial. Depending on the application and post-processing requirements, it can be used for both high-quality prototypes and final parts. Contact us at [email protected] for help selecting the right profile for your application.

Absolutely. Rapid changeovers let you cycle through different powders and profiles — including PA12 Industrial with Rapid Finish and other speciality powders — without lengthy downtime. Perfect for prototypes, small runs, and material testing.

No special tools beyond the standard accessories supplied with Lisa X and Suzy. Components are designed for quick disassembly and cleaning, making the process simple for operators of any experience level.

The printer guides you through switchover steps with on-screen instructions. Sinterit also provides video tutorials and documentation showing how to clean the printer and switch powders and profiles in minutes for safe, efficient transitions.

Application Engineer with six years of experience working with SLS 3D printing. He specializes in helping businesses discover how SLS 3D printing can empower their productivity and optimize costs.