3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

What is refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material

How does it work?

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material

– Store the powder at room conditions ( ~23°C and 50% humidity – the lower humidity the better)

– Always store the material in a sealed dry box/container.

– Do not leave the container open.

– Clean the machine directly after printing and store the material immediately after removing the print cake.

– Do not let the powder stay in the printer for more than a couple hours.

– Put a few silicone absorbers in the container (but don’t add them to the printer)

Contact Sinterit support with your questions.

The “Fresh” powder is the so-called Fresh powder that is not suitable for use in the printer. For the highest-quality printouts, make the “Print ready” powder from the “Fresh” powder. To do this, use the PHS or the Powder Sieve to mix the “Fresh” powder with the powder remaining in the printer after the last print.

Contact Sinterit support with your questions.

SLS polyamide powder used for 3D printing is considered particulate matter because of its size. Polyamide powder particles are generally 40 micrometers or smaller. If vacuumed in an ordinary vacuum cleaner, the powder could cause an explosion.

Such materials are subject to labor regulations on air quality and occupational safety. The procedures call for appropriate maintenance of powder at work. Only certified industrial vacuum cleaners should be used to clean such materials. More information about the ATEX Vacuum cleaner can be found here.

Contact Sinterit support with your questions.

PA11 Onyx is a bio-derived nylon powder known for its high strength, toughness, and impact resistance. It’s ideal for snap-fit designs, end-use parts, toolings, and components working under demanding conditions.

Yes, nitrogen is required during the printing process for this material.

It is compatible with Sinterit Lisa X and Lisa Pro printers.

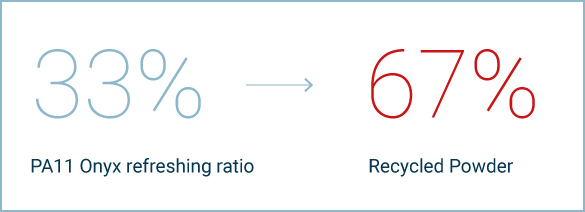

The refresh ratio is 33%, meaning 33% of fresh powder must be added for every new print cycle.

The printed parts are black, offering a clean and professional look suitable for functional prototypes and end-use components.

PA11 Onyx features a tensile strength of 55 MPa, flexural strength of 54.2 MPa, and an exceptionally high impact resistance of 179 kJ/m² (Charpy unnotched).

It has a melting temperature of 200 °C and a heat deflection temperature (HDT A) of 47 °C.

The elongation at break is 31.6%, indicating excellent ductility—well-suited for living hinges and flexible applications.

The powder has a particle size range of 28–80 µm with a mean size of 40 µm, providing good surface finish and detail resolution.

Yes, it is bio-based, derived from renewable sources, making it a more sustainable option among engineering polymers.