Produits

Knowledge

As SLS 3D printing is getting more popular, we share our insights, tips, and tricks for you to use.

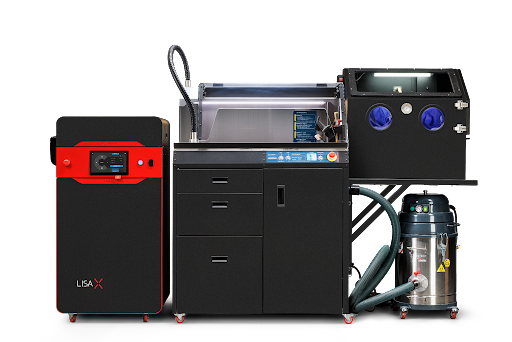

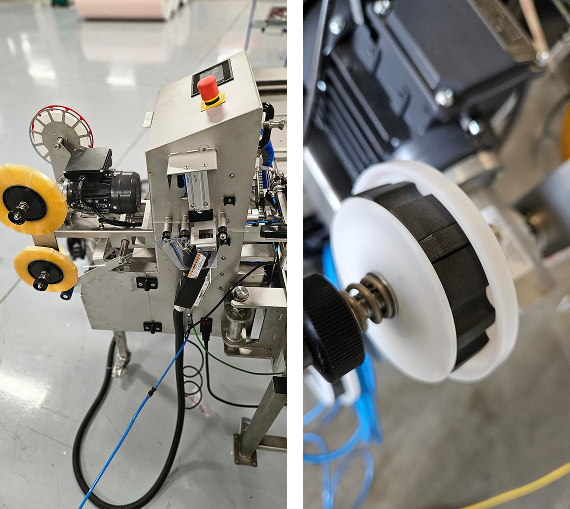

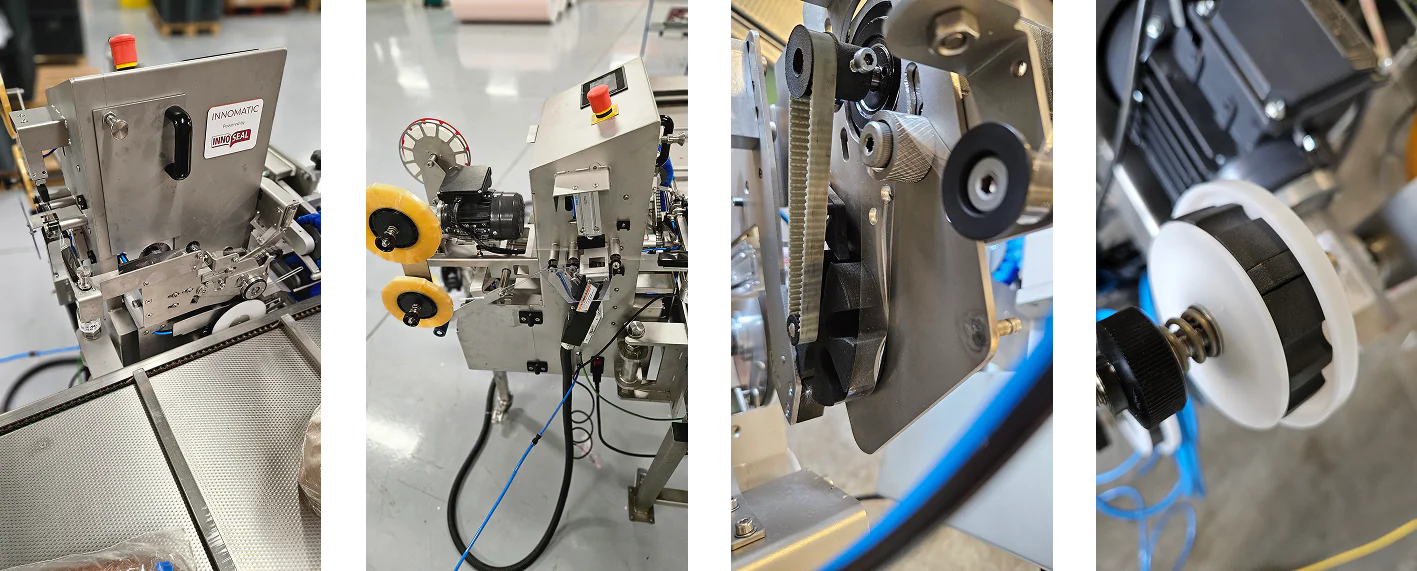

Case StudiesWith a four-figure installation worldwide of Sinterit's 3D printers, here you can find some of our client's stories.

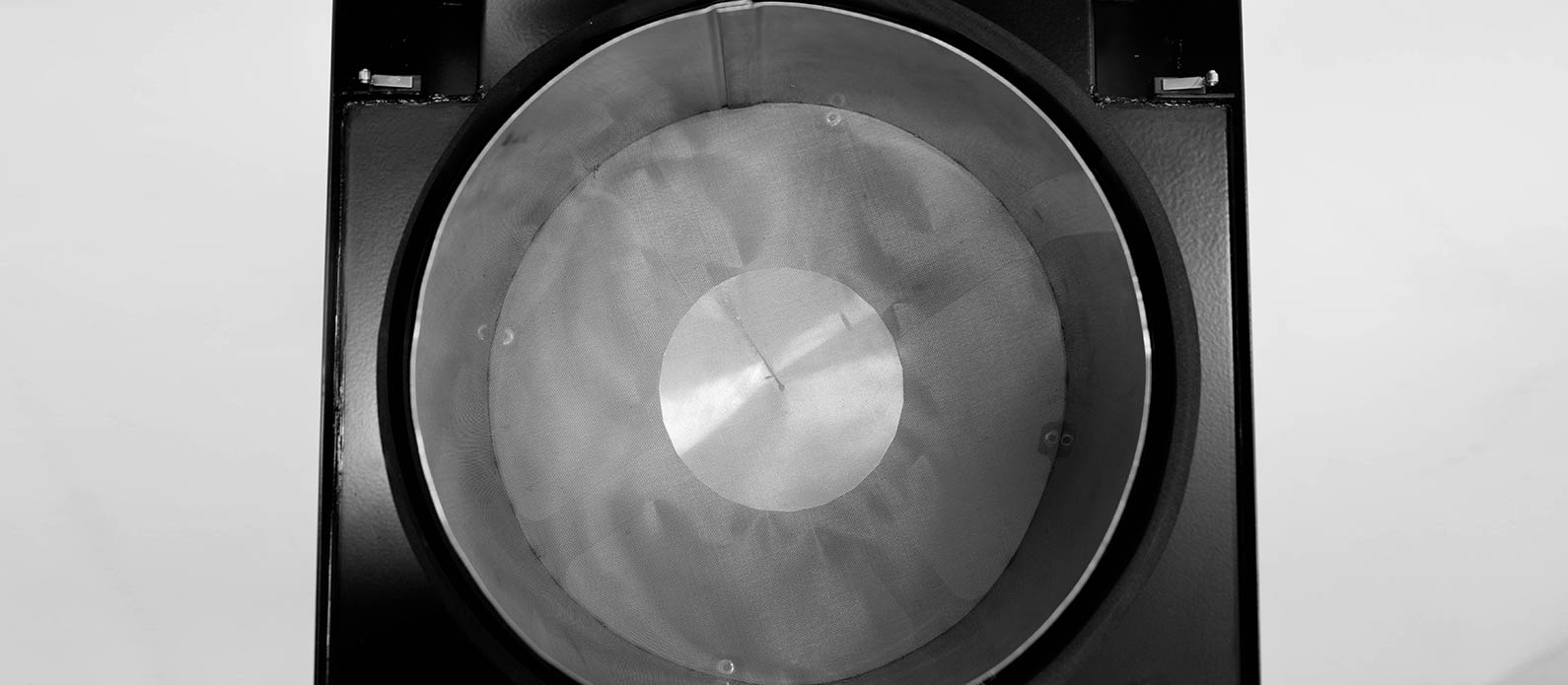

SLS TechnologyGrasp the basic knowledge about SLS. Your journey starts here.

WebinarsCheck the latest webinars about our products, SLS technology and more

EbooksDownload special ebooks about SLS 3D printing technology