3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

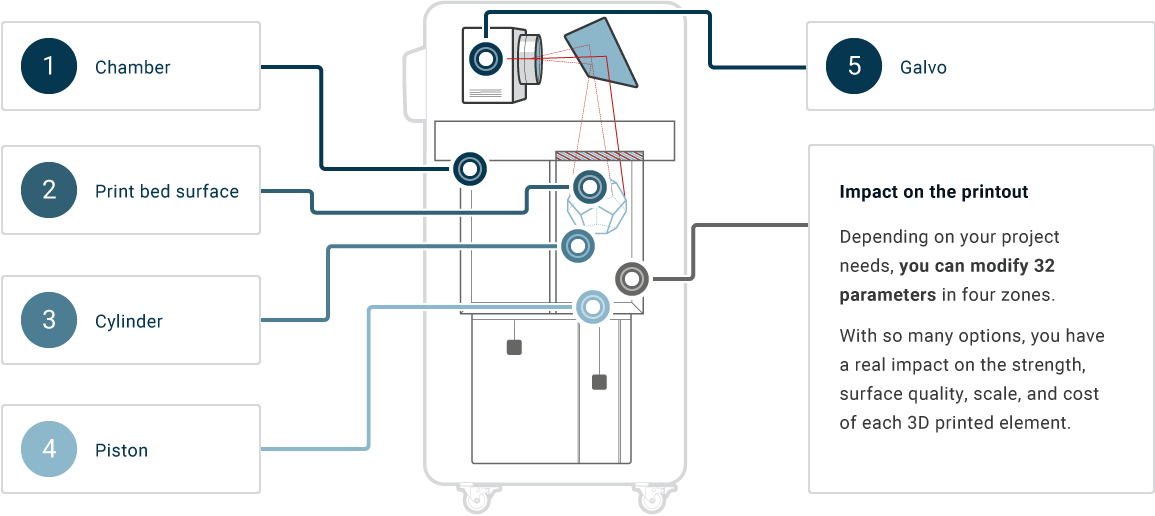

The 22 heating elements spread across four heating zones enable you to strictly control the temperature variations inside the printer. The resulting array of options for modifying and adjusting parameters allows you to optimize the printing process for developed materials, test new research methodologies, and make top-quality printouts.

Yes. The compatible powders are the profiles we provide with Sinterit Studio Advanced. They are tested by us and we can guarantee the results they’ll bring.

The open architecture of Sinterits solution allows users to edit existing profiles, and develop their own for non-compatible powders or even 3rd party materials. We recommend fixed profiles to inexperienced users, as the development requires time, knowledge, and resources, but with a confident R&D department it is entirely possible.

When in doubt contact us, and our team will advise you on the profile development.

The exact printing speed is dependent on a couple of factors, like layer height and build pack density. In almost all cases the whole process of printing, cooling, and post-processing takes up less than 24 hours, so you should be able to produce at least 5 full print beds per workweek.

The printing process is not complicated and can be learned in a short time even by staff members with no 3D printing experience. We offer 5-hour online training split into 2 sessions (basic + advanced, 2 weeks apart) as a part of the premium service plan.

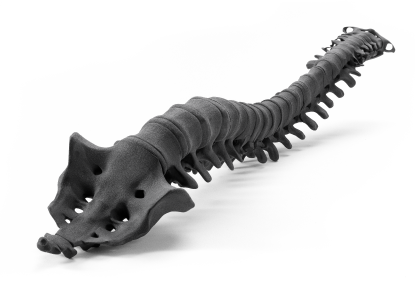

It’s entirely possible to print end products with LisaX! Choosing the right material and adjusting the printing parameters can bring great results in terms of meeting technical requirements for your part. We encourage you to contact us with any questions about your application – our Application Engineers gladly advise you.

SLS is in general very safe technology, as the materials used are for the most part not toxic, and safe to touch. Depending on your workspace setup some basic personal protective measures may be advised. LisaX is a part of the Performance set, which is ATEX certified to be a safe working environment.

The machine runs on single-phase power.