3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

Because it is crucial to know what the printing costs will be, we prepared this page, which you can use to learn about approximate costs of printing with Sinterit Lisa PRO and Lisa X.

How this was calculated?

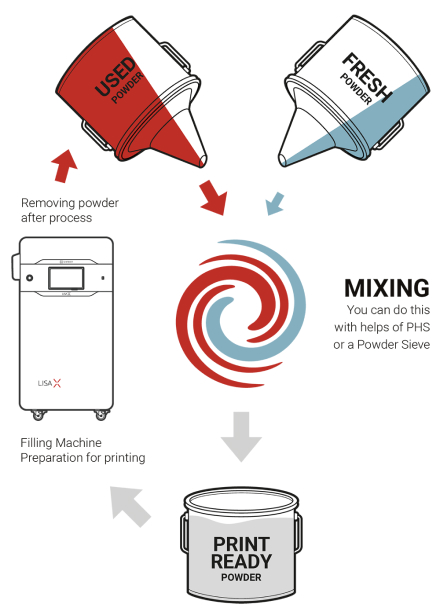

The calculation is based on the optimum density of the printout package. We calculated the 22% refresh ratio. Calculation is based on Sinterit PA12 Smooth powder.

Direct powder – Powder that is sintered during the printing process and becomes the printed part.

Refresher – Powder needed to refresh the unsintered powder, after the printing process.

This is the cost of PA12 Fresh powder needed to regenerate powder for the next printing process.