Surface finishing of molds for silicone casting – a comparative case study of FDM, SLA, and SLS

Introduction

In applications such as the manufacturing of molds for silicone casting, the 3D printing technology itself is not the sole factor determining the usability of the final component. The condition of the mold’s working surface is of critical importance, as it directly affects the quality of detail reproduction, the tightness, and the durability of the mold during repeated casting cycles.

In this context, post-processing methods – particularly vapor smoothing – play a crucial role. They not only enhance aesthetic appearance but, more importantly, enable functional modification of surface properties such as roughness, porosity, and tightness. Only the combination of an appropriate printing technology with a suitable surface finishing process makes it possible to meet the typical requirements for casting molds.

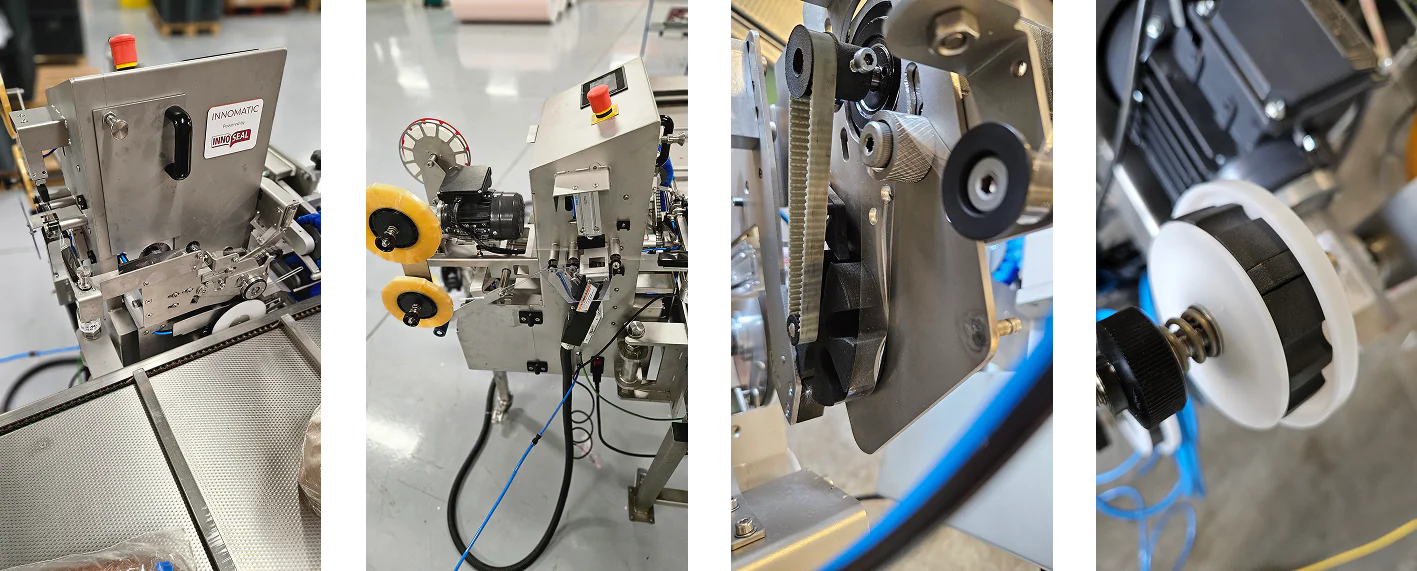

This case study compares three 3D printing technologies – FDM, SLA, and SLS – in terms of their suitability for producing silicone molds. The analysis is based on a practical test involving the fabrication of identical molds, casting them with the same silicone material, and evaluating the quality of the resulting cast parts. Special attention is given to the impact of the vapor smoothing process on the functional performance of molds manufactured using SLS technology. The molds used to produce a cable gland, which served as comparative samples, are shown in Figure 1.1.

Technical requirements for silicone molds

Molds intended for casting silicones (RTV, LSR, and low-viscosity PU) must meet the following technical requirements:

- low surface roughness (affecting both casting quality and ease of demolding),

- dimensional stability over time,

- surface tightness (absence of microporosity),

- resistance to repeated casting and demolding cycles,

- absence of surface defects (layer lines, support marks),

- sufficient mechanical strength of the mold material.

Comparison of 3D printing technologies in the context of manufacturing molds for silicone casting

The table below presents a comparison of three 3D printing technologies most commonly used for producing silicone molds.

| Technical parameter | SLS (after vapor smoothing) | FDM | SLA |

|---|---|---|---|

| Typical layer height [mm] | 0.075–0.125 | 0.1–0.3 | 0.025–0.05 |

| Surface roughness Ra [µm] | 1–3 | 10–25 | 1–5 |

| Visibility of layer structure | none | high | low |

| Support marks | none | none | present |

| Dimensional stability over time | high | medium | low |

| Deformation | minimal | possible | frequent |

| Surface tightness | high | low | medium |

| Mechanical strength | high | medium | low–medium |

| Durability in repeated casting cycles | high | low | medium |

Technical notes:

- The stated ranges represent typical values for standard materials, without the use of specialized resins or modified filaments.

- The surface roughness values are indicative (Ra) and depend on process settings and part geometry.

Molds manufactured using FDM technology

Molds printed using FDM technology, provided they are designed in a way that does not require support structures, are characterized by good geometric stability and low susceptibility to deformation. Thermoplastic materials maintain their dimensions over time, enabling predictable mold performance in short production runs. The main limitation, however, is the pronounced surface roughness resulting from visible layer lines and seams between deposited material paths.

Coating the surface with polyvinyl alcohol (PVA) facilitates demolding and partially compensates for surface irregularities, but it does not provide a smooth or fully sealed surface.

Conclusion: FDM is mainly suitable for prototype silicone castings and rapid geometry testing, where shape and dimensional accuracy are prioritized over surface quality.

Figure 1.2 below shows a section of the mold that required the use of support structures during printing, where reduced surface quality on the interior is clearly visible.

Molds manufactured using SLA technology

Molds printed using SLA technology offer significantly lower surface roughness compared to FDM, which in theory favors accurate detail reproduction. In practice, however, any surface supported by support tree structures requires manual sanding, which can be time-consuming and may lead to local distortions of the mold geometry.

In addition, photopolymer materials are prone to deformation and dimensional changes over time, even during the printing and post-curing stages. The brittleness of resins further limits mold durability under repeated casting cycles.

Conclusion: SLA is mainly suitable for molds intended for very fine visual details or test components, where surface quality is prioritized over process repeatability.

Figure 1.3 below shows a section of the mold manufactured using SLA 3D printing technology.

Molds manufactured using SLS technology with vapor smoothing

Molds printed using SLS technology are inherently characterized by high mechanical strength and excellent dimensional stability; however, the sintered surface is porous and not always fully sealed. The vapor smoothing process completely changes this situation—it reduces surface roughness, closes micropores, and imparts a level of smoothness that other technologies cannot achieve.

As a result, SLS molds after vapor smoothing combine high detail fidelity, dimensional repeatability, and surface tightness while maintaining the material’s mechanical strength.

Conclusion: In SLS technology, the absence of support structures and the ability to accurately reproduce fine details make these molds suitable for both short and long production runs of silicone castings. They therefore offer a level of functionality and durability that neither FDM nor SLA can achieve. Vapor smoothing is not merely a cosmetic treatment; it is a key process that transforms an SLS print into a fully functional mold that does not require polyvinyl alcohol (PVA) coating to facilitate demolding.

Figure 1.4 below shows a fragment of this type of mold.

Vapor smoothing as a key factor determining mold functionality

The vapor smoothing process leads to controlled plasticization of the material’s outer layer, resulting in reduced surface roughness and the sealing of micropores characteristic of sintered structures. In the context of silicone molds, this represents a significant change in the functional properties of the part, rather than merely a visual improvement.

Compared to mechanical or coating-based smoothing methods, vapor smoothing:

- acts uniformly across the entire surface,

- does not introduce additional material layers,

- does not cause localized geometric changes,

- improves surface tightness without loss of geometric detail.

As a result, printed parts can be used directly as silicone molds without the need for further surface post-processing.

Silicone castings – surface quality comparison

To verify the suitability of the individual technologies for producing functional molds, test silicone castings were made using molds printed with FDM, SLA, and SLS (after the vapor smoothing process). All molds were filled with the same silicone material under identical process parameters, allowing for a direct comparison of surface reproduction quality and geometric detail.

Figure 1.5 shows the molds after the silicone filling process.

Close-up views of the cast part surfaces clearly show the influence of the mold manufacturing technology on the structure and smoothness of the final component.

In the case of FDM molds, the texture resulting from the layered structure of the mold is visible and is transferred onto the silicone surface, as shown in Figure 1.6.

SLA molds provide a significantly smoother surface; however, localized marks from support structures and manual post-processing are still observable, as shown in Figure 1.7.

The most uniform casting surfaces were obtained from molds manufactured using SLS technology after the vapor smoothing process, with a representative surface fragment shown in Figure 1.8. Sealing the material’s porosity and reducing the mold’s surface roughness result in excellent detail reproduction and a continuous working surface, which is crucial for functional components such as seals, where both geometry and surface contact quality are critical.

Technical summary – recommendations

The comparative analysis shows that 3D printing technology alone is not always sufficient to meet the requirements imposed on silicone casting molds. The key factor is the ability to obtain a functional, tight, and dimensionally stable working surface.

Practical recommendations:

- FDM – suitable for rapid prototyping and geometry testing where surface quality is not critical.

- SLA – a good solution for short runs of visually detailed parts with high aesthetic requirements.

- SLS + vapor smoothing – the recommended technology for functional molds requiring durability, surface tightness, and consistent casting quality.

From this perspective, vapor smoothing is not an aesthetic add-on but a critical process step that transforms SLS 3D printing into a tool capable of real production applications in the field of silicone molds.