Transforming LED Lighting Production with In-House SLS Manufacturing at Indulite

How Sinterit LISA X, SUZY and a Complete SLS Ecosystem Enabled Fast Iteration, End-Use Production and Premium Finishing

“Special is Standard by Indulite”

What truly defines Indulite is its approach to customization. Rather than treating special requirements as exceptions, the company has built its business model around the belief that tailored solutions should be the norm. This philosophy is captured in Indulite’s slogan:

Special is Standard by Indulite.

Every project is approached individually, with luminaires engineered to meet specific technical, architectural, and functional demands. Geometry, mounting solutions, internal components, sealing features, and performance parameters are adapted to real-world applications — without compromise.

This level of flexibility places high demands on manufacturing. As product variations increase and development cycles shorten, Indulite continuously looks for technologies that allow them to turn ideas into production-ready components quickly, reliably, and sustainably.

The Business Reality: Customization at Scale

As the team explains:

We are specialized in building standard and or customized LED lighting fixtures on request for our customers needs and wishes…

Before SLS: Two Bottlenecks That Slowed the Business

Before implementing in-house SLS, Indulite faced two critical limitations that affected both development speed and production efficiency.

1) FDM printing did not meet end-use quality requirements

Although Indulite already used 3D printing, FDM technology proved insufficient for functional and final parts:

We did needed a better 3D printing solution than FDM printing, for end use and functional parts and prototyping.

Parts lacked the required mechanical strength, surface quality, and precision needed for professional LED products.

2) Outsourcing introduced long lead times and high costs

Relying on external printing services created delays and uncertainty:

We also were using Hubs / 3th party print services which resulted in problems like long lead times and high costs.

Injection molding was not a viable alternative for many components due to geometric complexity and high tooling costs:

Due to the complexity and geometric shapes of our parts it is not always possible to produce them with injection molding.

For a company driven by customization and fast delivery, these constraints limited innovation and slowed production.

Strategic Shift: Why In-House SLS Made Sense

- Agility — faster iteration and shorter lead times

- Quality — end-use mechanical performance and surface finish

- Sustainability — reduced transport and localized production

An additional driver was a Dutch government program supporting CO₂ reduction through in-house manufacturing:

The Dutch government had a program for companies when they were able to proof that they are able to reduce Co2 with in house producing with certain technologies they did subsidy those companies…

Partnering with Sinterit: More Than Just a Printer

We briefly looked into MJF printing but we did choose for SINTERIT due it’s way more affordable above the MJF systems, plus having the ability to reuse the used powders after refreshing it.

The Sinterit team supported Indulite in designing a complete, fit-for-purpose setup:

We came in contact with the SINTERIT Team and they helped and advised us with a setup off needed machines and variety of materials for the SLS printing process and post processing to our needs.

Due to SINTERIT’s fast support and professional advise we didn’t even look even further for another partner.

Dual-Printer Strategy: LISA X and SUZY Working Together

LISA X — Material Versatility and Advanced Applications

LISA X was selected for its broad material compatibility and advanced printing capabilities, including nitrogen-assisted printing:

We did invest in both machines due the variety of materials which only can be done on the Lisa X…

SUZY — Speed and Cost Efficiency

SUZY was added to increase throughput and reduce cost per part in higher-volume runs:

We do got SUZY due she is a bit faster and more affordable than the Lisa X…

By operating both systems simultaneously, Indulite can efficiently handle high part counts while maintaining material flexibility:

…when do high part counts we can use both at the same time…

The Ecosystem Advantage: A Complete End-to-End Workflow

What makes this case a strong reference is that Indulite didn’t stop at “we bought a printer.” They built a full ecosystem that supports:

- production consistency,

- professional finishing,

- powder reuse,

- and scalable throughput.

Ecosystem breakdown (why each stage matters)

- Design & slicing (Sinterit Studio) – fast iteration without tooling

- Printing (LISA X / SUZY) – material range and volume flexibility

- Depowdering (MULTI PHS) – powder recovery and preparation

- Surface cleaning (AMT POSTPRO DPX) – uniform surface finish

- Vapor smoothing (AMT POSTPRO SFX) – premium, end-use appearance

- Powder preparation (CADMIX II) – controlled refresh and reuse

- Nitrogen generation (CADMIA Nitro) – advanced material enablement

This integrated workflow ensures repeatability, cost efficiency, and professional finish across production runs.

Materials: Engineering for Real-World Performance

Indulite primarily uses industrial polyamides for functional parts:

We do used mostly use PA 12 Industrial and PA 11.5 powders.

For higher-performance requirements, carbon-filled materials are produced on LISA X with nitrogen assistance:

PA11 CF parts (using Lisa X with Nitro)

The ability to switch materials in-house allows Indulite to adapt quickly to different mechanical and application needs.

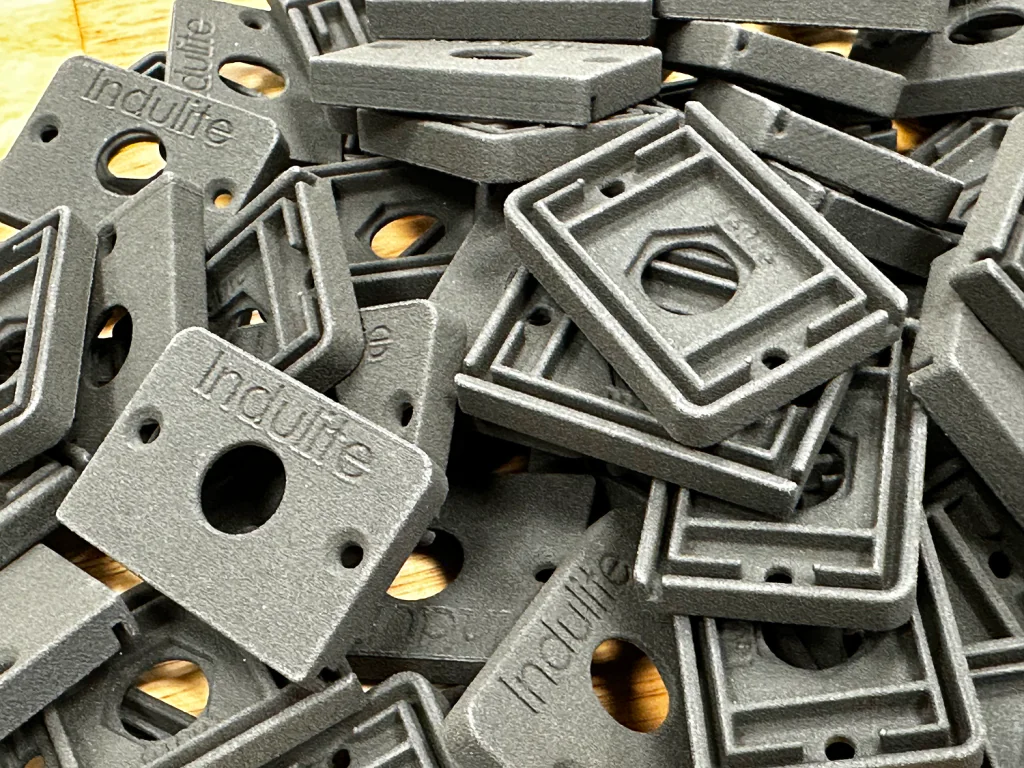

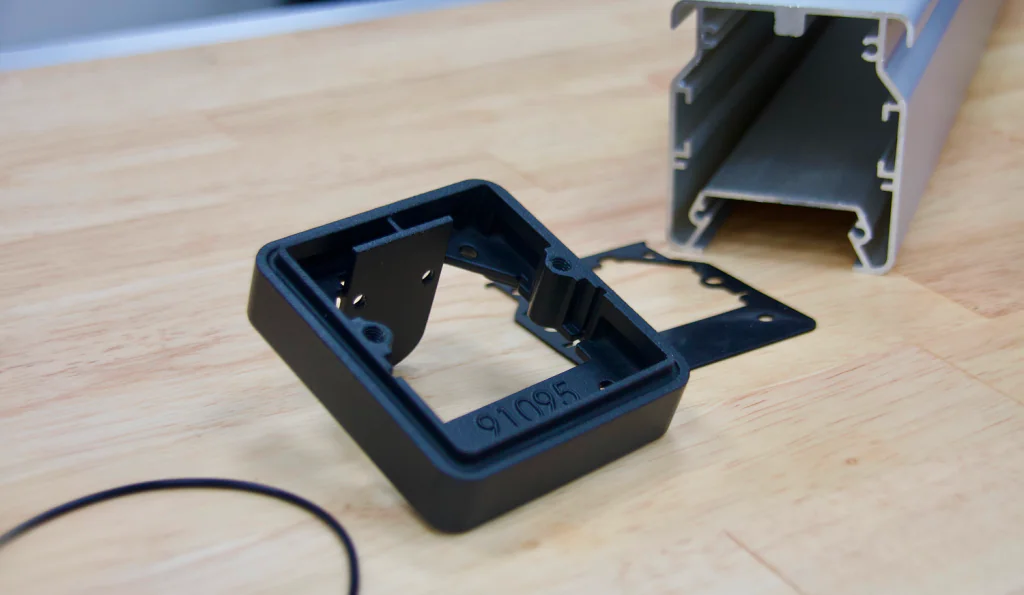

What Indulite Produces with SLS

Primary application: end-use components for LED products

We do print End Caps (3 types of parts) for our INDUSTRIA LED Line.

Additional application: internal tooling and spare parts

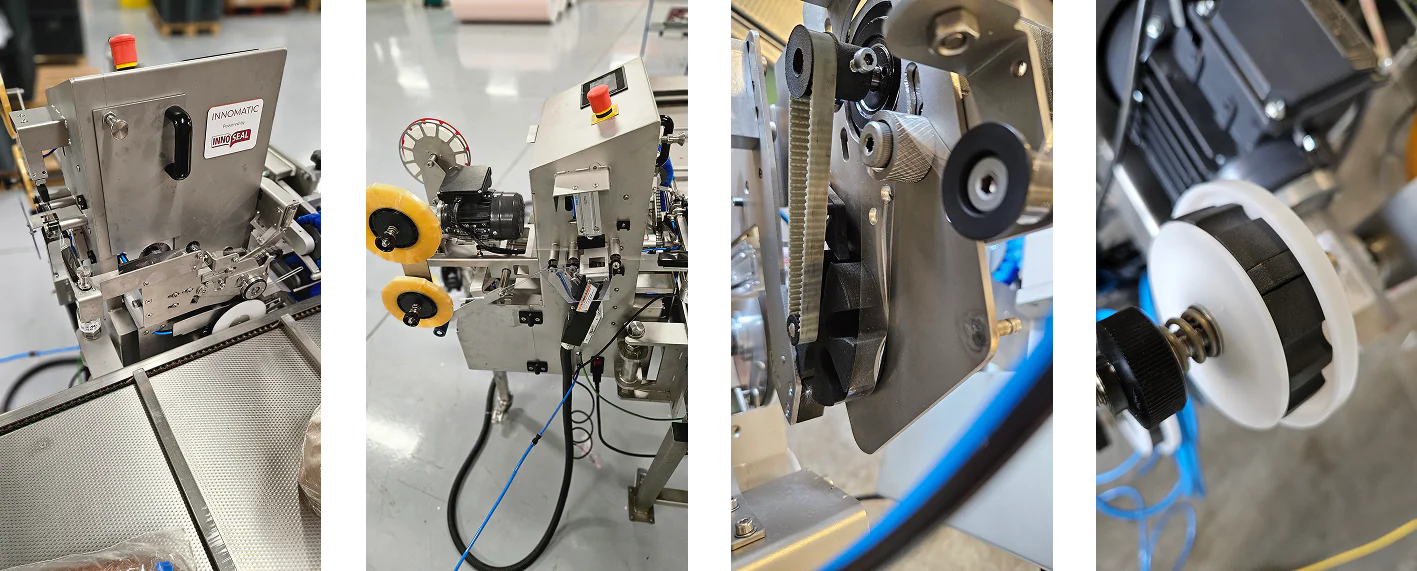

Functional spare parts for our in-house own build cable loom machine…

Monthly output:

We do approximately like 300 parts in the month average…

This confirms SLS as a true production technology — not just a prototyping tool.

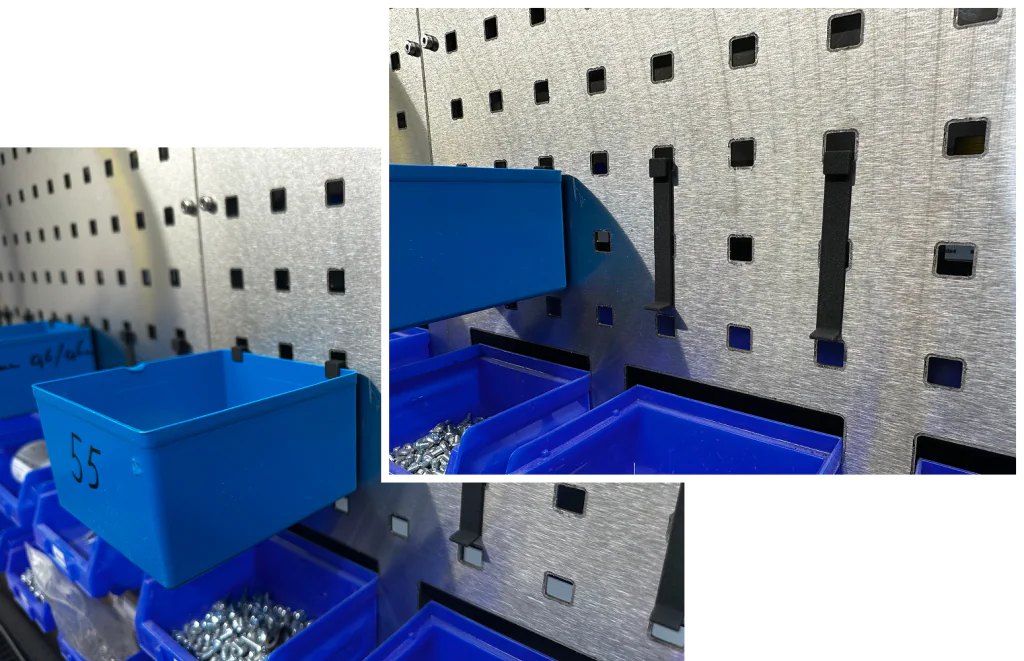

We invite you to watch the video below, which presents Indulite’s complete post-processing workflow and day-to-day SLS manufacturing process. The company uses Sinterit printers and the full SLS ecosystem not only to produce end-use components for customer products, but also to manufacture functional parts for internal use — such as components for new workbenches designed to mount storage bins on pegboards — further optimizing efficiency, flexibility, and overall production flow.

Results: Measurable Impact on Speed and Flexibility

Lead time reduction: 35 days → ~2 days

Indulite provides a clear comparison between overseas injection-molded ordering and in-house SLS:

If we do order injection molded parts in China for example it will take at least 35 days… now we do can print them in house and will take about 2 days…

This is not just incremental improvement. It’s a shift from a month-long wait to a couple of days—transforming how fast manufacturing can start and how quickly designs can evolve.

Faster prototyping & production readiness

We do save a lot of time with Prototyping and producing parts in house instead of long lead time…

Higher flexibility for customization

The flexibility of changing parts and or adjusting them to our customer needs.

The strategic result: Indulite can respond to customer demands rapidly—without the cost and schedule burden of outsourcing or tooling.

Why This Matters for the LED Lighting Industry

The Indulite case demonstrates a repeatable model for manufacturers producing customized, geometry-rich components:

- Use SLS for complex parts that are difficult or costly to mold

- Keep iteration and production in-house to shorten development cycles

- Combine printing with post-processing for premium finish

- Scale output with complementary machines

- Improve sustainability through powder reuse and localized production