What is the future of 3D printing?

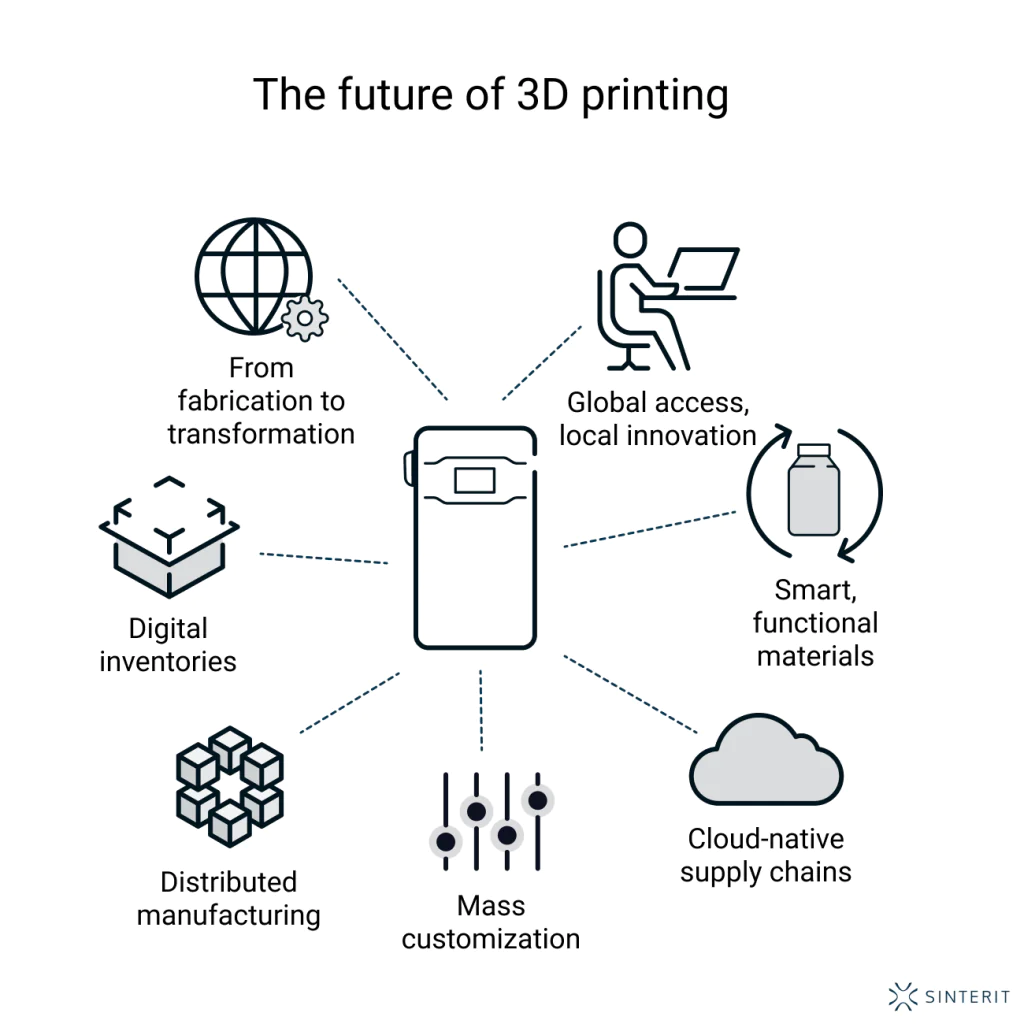

Additive manufacturing has already proven itself as a tool for prototyping and small-batch production. But the next frontier isn’t just about printing better parts — it’s about reshaping how entire industries design, source, and deliver products. So how will 3D printing change the world? By changing the systems that make it run.

The future of 3D printing lies in decentralization, digitization, and on-demand capability — and those shifts are already underway.

Manufacturing anywhere, anytime

Perhaps the most transformative potential of 3D printing is its ability to bring production closer to the point of need. Instead of relying on centralized factories, goods can be manufactured locally, even remotely, using digital files and compact, versatile equipment.

This decentralization reduces reliance on global supply chains, shortens lead times, and allows for true just-in-time manufacturing. It also holds enormous potential in disaster zones, rural areas, or even space missions — where shipping spare parts is impractical or impossible.

Will 3D printing change the world? It already is — by redefining what “production” means and where it can happen.

From standardization to personalization

Mass production was built on the logic of identical parts. But consumers and industries are demanding more tailored solutions — whether it’s a custom medical implant, ergonomic tool, or uniquely styled consumer product.

3D printing enables mass customization at scale. Designs can be adjusted digitally with no tooling changes or added setup costs. This unlocks new business models based on personalization, short-run editions, or regionalized product variants — without sacrificing efficiency.

How is 3D printing changing the world? By shifting the design paradigm from “one-size-fits-all” to “fit-for-one”.

Smarter digital supply chains

In the near future, physical warehouses may give way to digital inventories — where spare parts, tools, and fixtures are stored as files rather than stock. These parts can be printed on-demand, close to where they’re needed, reducing overproduction and obsolescence.

This approach not only saves material but also strengthens resilience. Companies gain agility in responding to disruptions, market shifts, or design updates — with far less friction. Additive manufacturing becomes a key enabler of more responsive, digital-first logistics.

Material innovation and functional integration

While hardware will continue to evolve, the real leap lies in functional 3D printing — where parts are not just structures, but systems. Multi-material printers capable of embedding sensors, conductors, or actuators will allow us to create parts that sense, communicate, or respond to their environment right off the build plate.

We’re also seeing progress in bio-printing, conductive polymers, and smart composites that bring entirely new functionality into play. These advances blur the line between manufacturing and material science — and redefine what a “part” even is.

Education, democratization, and the next generation of makers

The accessibility of 3D printing is cultivating a new generation of engineers, designers, and problem-solvers. With affordable machines, open-source platforms, and cloud-based design tools, innovation is no longer confined to large R&D labs.

Students, startups, and hobbyists can now prototype and iterate on ideas with the same tools used in high-end industries. This democratization of manufacturing knowledge may be one of the most powerful long-term impacts of 3D printing — empowering local innovation on a global scale.

Looking ahead

So, what is the future of 3D printing? It’s not just more accurate printers or faster builds. It’s a fundamental shift in how we create, deliver, and experience the physical world. As the technology matures, its greatest influence may not be in how parts are made — but in how industries, economies, and people rethink what’s possible.

Explore also

- Is 3D printing the future?

- Future uses of 3D printing

- 3D printing vs traditional manufacturing

- What will 3D printers be used for in the future

- Trends in additive manufacturing

- AI in 3D printing

- Automation 3D printing

- Next-generation 3D printing materials

Related categories

Austria

Austria  Bosnia and Herzegovina

Bosnia and Herzegovina  Bulgaria

Bulgaria  Croatia

Croatia  Czech Republic

Czech Republic  Denmark

Denmark  Estonia

Estonia  Finland

Finland  France

France  Germany

Germany  Greece

Greece  Hungary

Hungary  Ireland

Ireland  Italy

Italy  Latvia

Latvia  Lithuania

Lithuania  Poland

Poland  Portugal

Portugal  Romania

Romania  Slovakia

Slovakia  Slovenia

Slovenia  Spain

Spain  Sweden

Sweden  Switzerland

Switzerland  United Kingdom

United Kingdom  Ukraine

Ukraine  China

China  Hong Kong

Hong Kong  India

India  Israel

Israel  Japan

Japan  Malaysia

Malaysia  Philippines

Philippines  Saudi Arabia

Saudi Arabia  South Korea

South Korea  Taiwan

Taiwan  Thailand

Thailand  Turkey

Turkey  United Arab Emirates

United Arab Emirates  Egypt

Egypt  South Africa

South Africa  Tunisia

Tunisia  Canada

Canada  Mexico

Mexico  United States

United States  Brasil

Brasil  Colombia

Colombia  Australia

Australia  New Zealand

New Zealand