Real-world 3D printing examples that are shaping today’s industries

3D printing is no longer a novelty. It’s a transformative force powering innovation across engineering, healthcare, aerospace, and even art. Below, we explore the most compelling examples of 3D printing in real life, showing how this technology solves real problems, speeds up production, and personalizes solutions like never before.

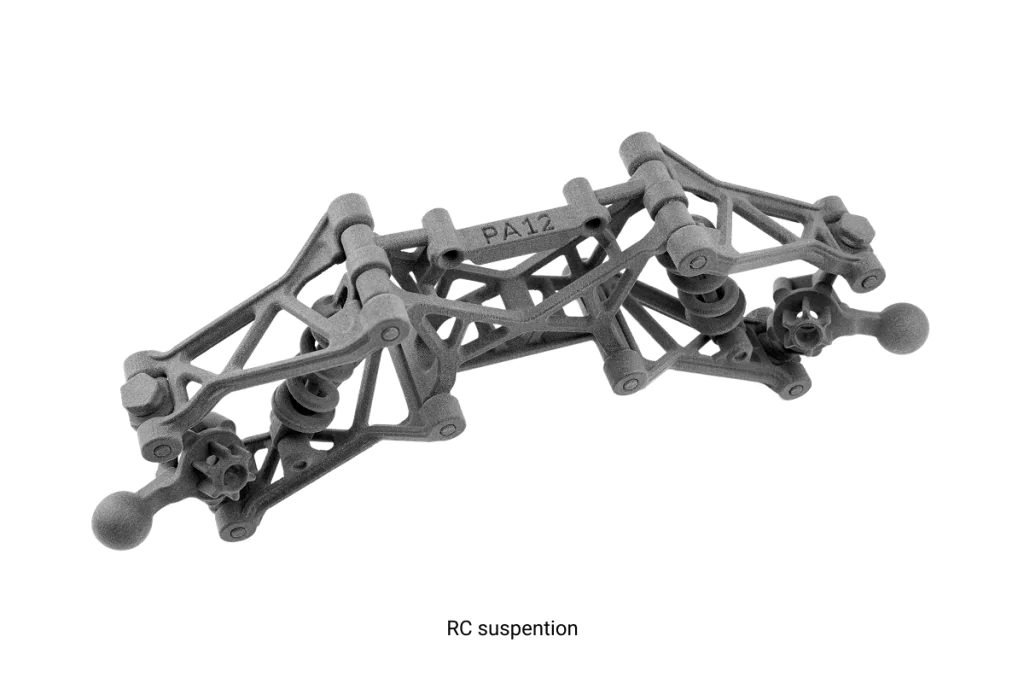

1. Rapid prototyping in product development

Perhaps the most established use case of 3D printing is rapid prototyping. Companies in automotive, consumer electronics, and industrial design leverage 3D printers to create early-stage prototypes that can be tested, iterated, and refined — all within 24 to 48 hours.

Instead of waiting weeks for machined prototypes, engineers can move from CAD design to physical model in a day, drastically cutting down development cycles and enabling faster innovation.

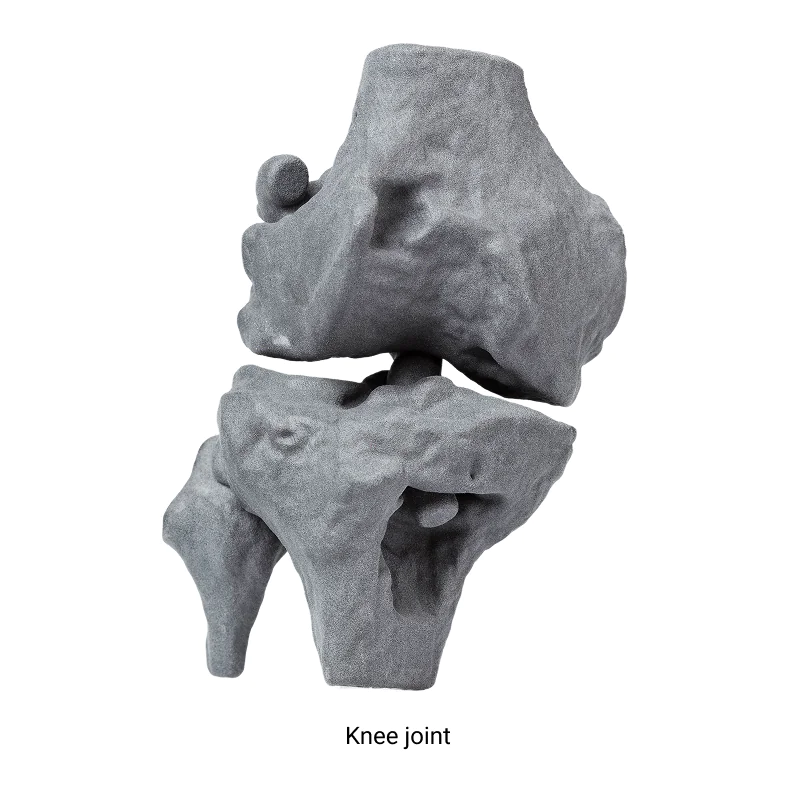

2. Customized medical devices

One of the most meaningful 3D printing examples in real life is its application in healthcare. From patient-specific prosthetics to surgical models and orthopedic implants, 3D printing empowers doctors to deliver care with a level of precision that traditional manufacturing can’t match.

With the ability to print directly from CT or MRI scans, clinics can now produce:

- custom-fit orthotics,

- dental aligners and crowns,

- biocompatible surgical guides.

The result? Better patient outcomes, faster recovery times, and lower production costs.

3. End-use functional parts in aerospace and industrial sectors

Gone are the days when 3D printing was limited to prototypes. Today, it’s being used to manufacture fully functional end-use parts — particularly in aerospace, automotive, and heavy industry.

Real example:

Airbus and SpaceX use 3D printed metal brackets, fuel nozzles, and housings that are:

- lighter than machined parts,

- topology-optimized for strength,

- manufactured with less waste.

This ability to print high-performance components on demand is changing how supply chains operate.

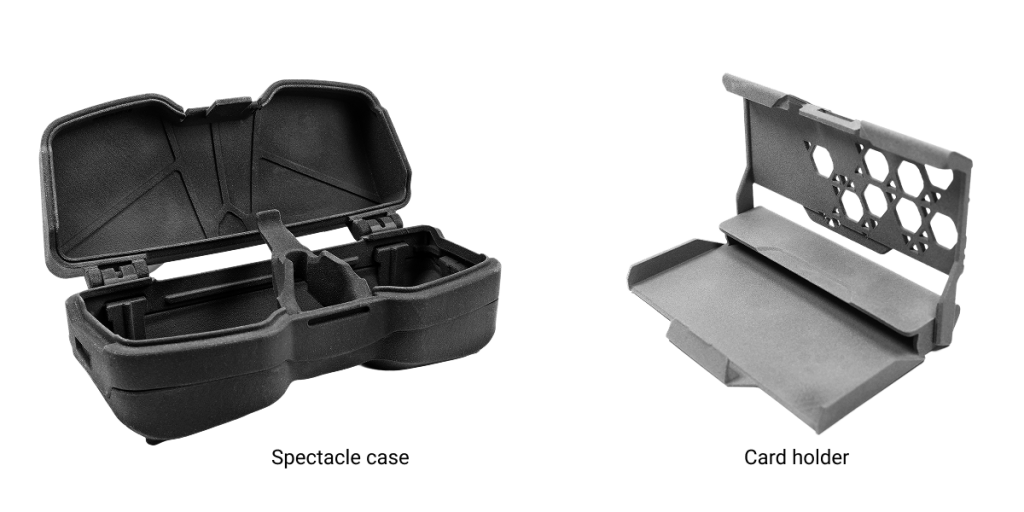

4. Educational and creative everyday uses

While high-tech industries drive much of the spotlight, 3D printing also impacts everyday life in subtle but powerful ways:

- replacement parts for home appliances,

- personalized smartphone stands or cable organizers,

- anatomical models for STEM education,

- custom décor and fashion accessories in art and design.

From classrooms to living rooms, 3D printing enables anyone to go from idea to object with astonishing ease.

Why these 3D printing examples matter

Across all these industries, the core advantage of 3D printing is the same: freedom from traditional manufacturing constraints. Whether it’s a hospital customizing a bone plate or an engineer testing a new drone propeller — 3D printing makes it possible to innovate faster, smarter, and more efficiently.

Explore also

- What is print 3D? Concept of 3D printing

- What does “3D printed” mean?

- How does 3D printing work?

- Slicing in 3D printing

- What do you need for 3D printing?

- 3D printing benefits

- Is 3D printer dangerous? Understanding the real risks

- 3D printing issues

- 3D printing history

- 3D printing facts

- Who uses 3D printers? Not just for engineers anymore

- Where 3D printing is used

- 7 common 3D printing myths

- 3D printing global market

- Cultural impact of 3D printing

- Hybrid manufacturing (CNC + AM)

Related categories