5 most common myths about SLS powder handling

3D printing is a relatively new technology, and as such, it brings a lot of questions to the table. People aren’t sure how it works, if it’s safe, or what it requires. Lack of knowledge often gives life to myths, making the technology seem much more cumbersome and threatening, than it really is. In case of the SLS method used for sintering polyamide and other plastic powders, one of the most commonly discussed and demonized topics is powder handling. Let’s take a look at the issue and clarify what’s real and what’s not.

Myth #1 It’s toxic, I don’t want it near me

One of most commonly made errors is the assumption that powders used in SLS 3D printing are toxic. One source of that myth actually comes from a different 3D printing technology – ultra-fine particles emitted by FDM printers can indeed have harmful effects when breathed in, similar to smoking12. That doesn’t happen in our case, because particles used during SLS printing are much larger – over 40 microns in diameter (78 microns in average), which makes them harder to lift into air (and you’d have to take a good sniff inside the printer when it’s working anyway). The other reason behind that misconception – and possibly its root cause – is the fact, that we recommend using protective gloves, glasses and masks. But that actually isn’t because of the powders’ toxicity – they’re completely safe, meet all the standards, have all the required safety certificates. So, why, you might ask, all these protective measures? Because it’s practical. You see, when it comes to consistency, our powders are kinda like flour. The fact that flour isn’t toxic doesn’t exactly mean, that you want it in your eyes, mouth (at least before it’s baked) and on your clothes, right? The same applies to our products.

Myth #2 It makes a mess, who has time for so much cleaning

It kind of does, there’s no way around that. But it’s definitely not as bad as some are making it seem3. Since we mentioned flour above, let’s use a comparison to baking. When a baker makes bread, he uses a certain place for it and there’s a reason for that. When you bake yourself (or your wife / husband does), you usually do it in the kitchen, right? For a moment there, it can look a bit messy – the flour is everywhere, pots and dishes need some scrubbing – but it’s nothing that can’t be cleaned in an hour or so. Our powders are usually even less problematic. So, technically – yes, there can be a bit of a mess at times – but it’s nothing major. Usually you just have to clean the tools, a single table that’s used for post-processing (cleaning and dusting off of printed structures) and maybe a little bit of floor around it – just like how it is after baking.

Myth #3 It requires a lot of space, it won’t fit in my office

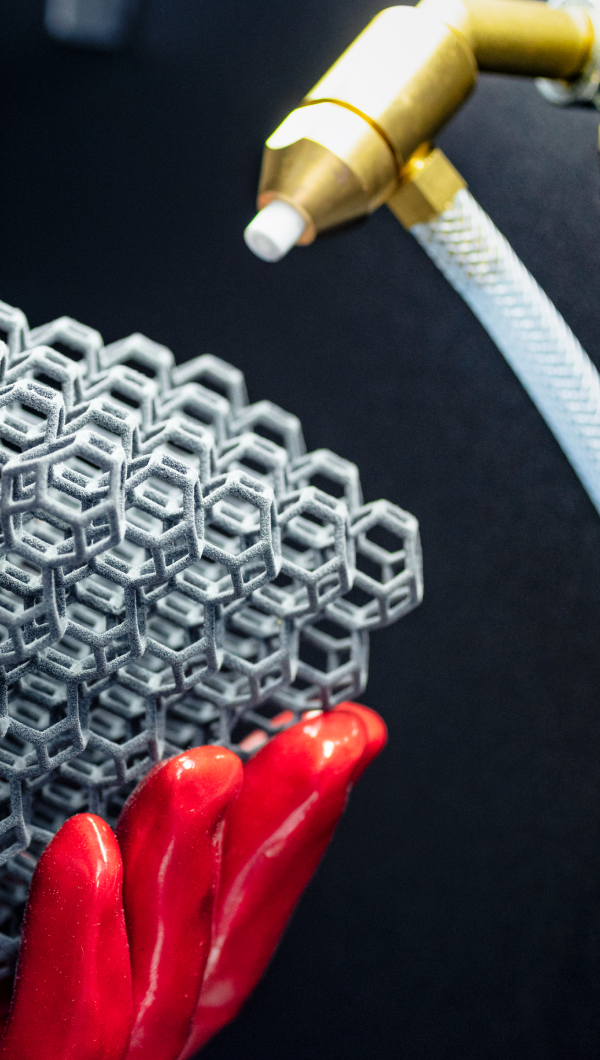

This one used to be true – before we came around, that is. SLS machines used to be these large, industrial monsters, completely unfit for home/office use, with a whole company infrastructure dedicated just for powder handling4. Now, thanks to Sinterit Lisa, all you need is a place for the printer (it can stand on a large enough desk or near a wall/in a corner of the room), a single table for post-processing work, and a little bit of space for an optional sieving station (it’s about a knee length high, the size of a small kitchen closet). And with that, you’re all set.

Myth #4 Powder handling is complicated, requires complex knowledge and instructions

It really isn’t and it really doesn’t. In essence, you just remove the unused/unsintered powder from the printer, put it in the sieve, add some fresh material (the correct ratio is 7/3 – seven parts used to three parts new – it’s mentioned in the documentation that comes with the printer) and let the station do its magic. Even if you were to sieve it all manually, it actually wouldn’t be all that complicated. You don’t need a Master’s Degree in chemistry, you don’t need any engineering knowledge – you just need a sieve, a simple instruction and a little bit of common sense.

Myth #5 Powder handling is time consuming – it’s time I don’t have

Once again – not really. Of course, sieving everything manually would definitely take quite a bit of your time and make things bit more dusty, but that’s precisely why we created our automated sieve. With it, you pretty much just dump everything inside (beside the printed objects of course), press a button – and forget. It doesn’t require any kind of supervision, so you can go about your day normally, doing whatever you want – working, watching kids relaxing etc. Then, after a while (one sieving cycle takes about 15 minutes), you come back, and just collect the ready-to-use powder. In essence, all the work is done for you, so your time isn’t affected at all.