Is SLS 3D printing a good fit for durable end-use parts?

Selective Laser Sintering (SLS) is no longer limited to rapid prototyping – today, it’s a viable solution for producing durable, functional end-use parts with 3D printing. As industries demand faster turnaround, higher customization, and supply chain flexibility, SLS 3D printing has positioned itself as a bridge between prototyping and low-to-mid volume production. But is it always the right choice for end-use applications?

Material properties close to injection molding

A core advantage of Selective Laser Sintering is its ability to produce parts with mechanical properties comparable to injection-molded plastics, making it a compelling choice for manufacturing 3D printed end-use components. This is largely due to high-performance materials used in the SLS process, such as polyamide 12 (PA12), polyamide 11 (PA11), and composite variants reinforced with carbon or glass fibers.

These materials offer excellent strength-to-weight ratios, high thermal resistance, and robust chemical durability.

- PA12 offers toughness and fatigue resistance, ideal for load-bearing parts like automotive brackets or electronic housings.

- PA11 adds flexibility and impact resistance, making it great for sports gear or living hinges.

- Carbon-fiber-filled nylons increase stiffness and heat resistance – perfect for UAV frames or high-stress automotive parts.

Because SLS builds parts without the need for support structures and allows for complex geometries, these mechanically robust materials can be used in intricate, customized designs without compromising structural integrity.

As a result, SLS has evolved from a prototyping tool into a reliable method for manufacturing low- to mid-volume batches of end-use parts in industries where performance and precision are critical.

Surface finish and post-processing needs

Parts directly off the SLS printer typically have a slightly rough, grainy texture due to the nature of the powder-based sintering process. This finish, while sufficient for many internal or functional components, may not meet the aesthetic or tactile requirements for consumer-facing products or components used in environments where friction, hygiene, or chemical sealing are concerns.

As a result, post-processing becomes an important step in transforming SLS-printed parts into fully viable end-use products. Techniques such as media blasting are commonly used to smooth and unify the surface texture, while dyeing can provide uniform color throughout the part without masking fine details – unlike surface paints or coatings. For higher-end applications, vapor smoothing chemically polishes the outer layer, reducing surface porosity and enhancing both visual appeal and resistance to moisture and contaminants.

For a deeper look at how vapor smoothing enhances the surface quality and performance of SLS-printed parts, check out our dedicated article on the topic here.

Practical advantages of SLS for end-use production

Beyond material performance and design freedom, SLS 3D printing offers practical advantages for manufacturing functional end-use parts.

Convenience is one of SLS’s key benefits. Unlike injection molding, which requires a custom mold for each part and confines production to one geometry per cycle, SLS allows multiple different parts to be printed simultaneously – as long as they fit within the machine’s build volume. This is ideal for custom components, assemblies, or product variants without extra setup costs or downtime.

Additionally, since SLS does not require support structures, there’s no need to design or remove them. This support-free printing expands design possibilities and results in consistent surface aesthetics without blemishes or marks that supports often leave behind.

From a time-saving perspective, SLS enables highly efficient production workflows. It allows tightly nested parts in the build chamber, regardless of shape or orientation. This “batch printing” capability supports overnight or weekend production, without supervision. Unlike some additive technologies that require frequent intervention, SLS enables longer, uninterrupted print cycles, leading to higher throughput with minimal operator involvement.

Cost efficiency

SLS also delivers strong economic benefits, particularly when compared to traditional manufacturing methods.

The cost of injection molds can range from thousands to tens of thousands of euros, creating a major barrier for startups or companies developing new products. With SLS 3D printing for end-use parts, this tooling cost is completely eliminated – parts go directly from design to production.

This is especially valuable in early-stage development, where frequent iterations are needed, and in low-volume manufacturing where tooling investment is hard to justify. Additionally, with optimized nesting and powder reuse, SLS can be surprisingly cost-efficient – especially when producing multiple parts in one print run.

Together, these benefits – ease of use, production efficiency, and cost-effectiveness – make SLS an accessible, scalable solution for companies looking to produce durable, high-quality end-use parts without the cost or rigidity of traditional methods.

What sbout disadvantages?

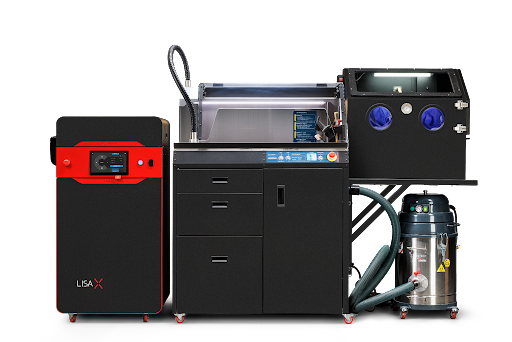

While SLS offers many advantages for end-use production, certain limitations may remain difficult and considered in long-term manufacturing strategies. One of the main challenges is the cost of industrial SLS machines, which can be prohibitive for small businesses or those not operating at scale. Health and safety concerns around powder handling might also present a barrier, as the fine particles require strict environmental controls, protective equipment, and proper ventilation, adding complexity to facility setup and operation. Build size constraints are another factor, requiring oversized parts to be split into segments and assembled, which can weaken structural integrity and increase labor costs. These limitations are not easily resolved with simple process improvements or post-processing steps. Understanding these challenges is essential to making informed decisions about where and when SLS is truly the best fit for end-use manufacturing.

Conclusions

SLS 3D printing is a strong option for producing end-use parts, combining durability, design freedom, and efficient batch production. It’s especially useful when moving quickly from prototype to product without investing in molds.

While it has some limits – like surface finish and machine accessibility – its advantages often outweigh the trade-offs.

With the right application and realistic expectations, SLS can be a smart, flexible solution for manufacturing functional 3D printed parts that meet real-world demands.