Rapid Finish: a new era of speed for Lisa X and PA12 Industrial

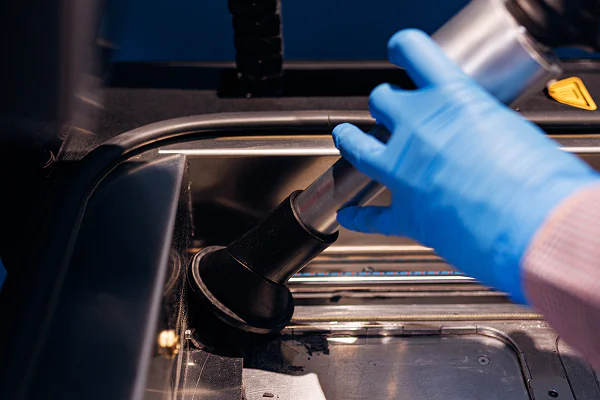

As additive manufacturing continues to push the boundaries of efficiency and sustainability, more and more companies are looking for smart ways to cut costs without sacrificing part quality. One promising area of innovation is powder reuse — specifically, repurposing used PA12 powder from Multi Jet Fusion (MJF) processes for Selective Laser Sintering (SLS) on open-platform printers like the Sinterit Lisa X.

From Suzy’s speed to Lisa X’s versatility

Suzy was built with a singular mission — to be the fastest SLS printer for PA12 Industrial. In doing so, we developed new print strategies and optimizations that have now been adapted for the Lisa X.

While Suzy remains faster — about 35 – 40% faster than the old Lisa X “Quality” profile — Rapid Finish closes much of the gap, delivering a 25 – 30% speed improvement. This is achieved even though Lisa X is a more general-purpose machine with an open environment, multi-material support, and easy material changes.

It’s worth noting that Suzy is mechanically optimized for PA12 Industrial and benefits from design choices aimed purely at maximizing throughput and reducing operating costs for that single material. Lisa X, on the other hand, balances speed with flexibility — making Rapid Finish a powerful tool for users who need both.

Replacing the old “Quality” profile

The new Rapid Finish profile replaces the old “Quality” profile for PA12 Industrial. Our tests showed that “Quality” no longer brings any real-world advantages over Rapid Finish. With the same cost per build but much faster turnaround, Rapid Finish is now the best choice for high-detail PA12 Industrial prints on Lisa X.

Return on Investment – Rapid Finish in action

The Rapid Finish profile isn’t just about saving hours—it’s about unlocking real business value.

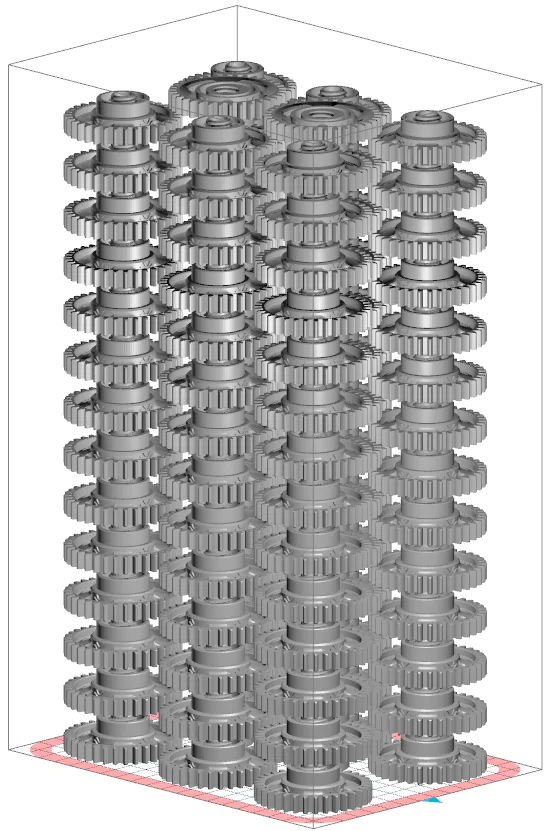

Example 1 – 112 small gears

With Rapid Finish, Lisa X completes this job in 38h 36m, compared to 51h 18m with the old “Quality” profile—a 25% faster turnaround. Suzy does it in 28h 59m, but the gap has closed considerably.

In-house cost per build: €111.59.

Outsourcing costs (examples from five anonymized providers): €290–€1,287, with lead times from 3 to 30 days.

Even with the slowest in-house setup, Lisa X production is up to 11× cheaper than outsourcing—and Rapid Finish gives you the parts several days sooner.

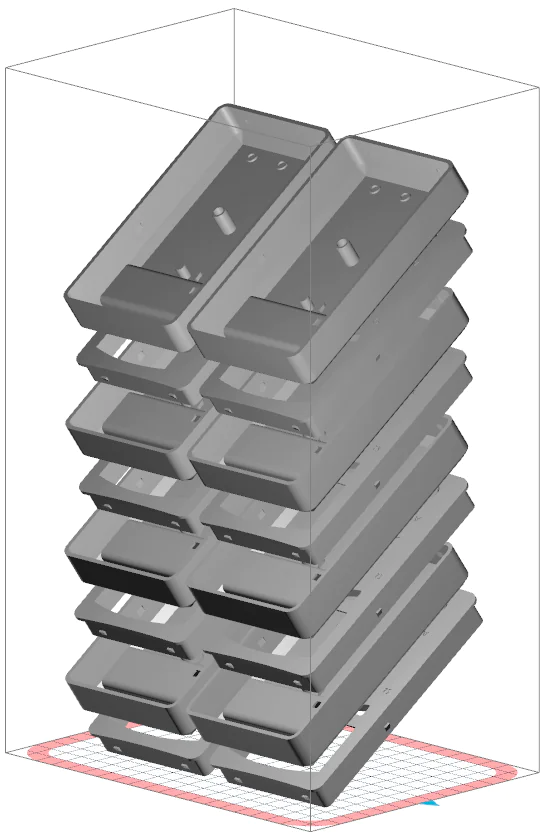

Example 2 – 8 two-part multimeter housings

Rapid Finish completes this job in 28h 59m, versus 40h 9m with the old “Quality” profile—28% faster. Suzy still leads at 20h 50m.

In-house cost per build: €105.64.

Outsourcing costs (five anonymized providers): €109–€548, with lead times from 3 to 30 days.

With Rapid Finish, Lisa X delivers finished parts in just over a day, making it an ideal solution for urgent production needs.

Key ROI takeaways

- 25–30% faster printing with PA12 Industrial on Lisa X increases weekly throughput and reduces customer lead times.

- Stable in-house production costs keep pricing predictable while speeding up delivery.

- Substantial savings vs outsourcing—often covering the printer’s cost in avoided service fees within months.

- Control over delivery—no shipping delays, no external queues, no minimum order restrictions.

Lisa X vs. Suzy – different strengths, shared DNA

Lisa X advantages:

- Open printing environment for process flexibility

- Multi-material capability

- Quick and simple material changeovers

Suzy advantages:

- Unmatched printing speed for PA12 Industrial

- Optimized mechanical design for reduced per-part costs

- Built for maximum throughput and affordability in dedicated PA12 production

Summary

The Rapid Finish profile brings Lisa X users a significant speed boost for PA12 Industrial—without changing hardware or increasing costs. While Suzy remains the fastest Sinterit printer for this material, Lisa X now offers a performance level that makes it a competitive choice for time-sensitive, high-quality production, especially when flexibility is also a priority.

This update is free for every Lisa X user and is available now. Download here.