We finalized major order and secure fresh financing amid industry challenges

Even in today’s turbulent global market, we’ve achieved a major milestone: FIT Additive Manufacturing Group in Germany, one of our key shareholders, has placed an order for more than thirty of our Lisa X and Suzy 3D printers. Alongside this order, FIT has also provided us with a working capital loan to fuel our next stage of growth.

Carl Fruth, CEO of FIT AG, highlighted why this partnership matters: “The additive manufacturing market is extremely challenging for many companies at the moment. But we believe that a new industry is emerging, in which the combination of AI and 3D printing will deliver the additive manufacturing promise: High specification products with short lead-times and competitive cost. Sinterit’s range of SLS machines delivers exactly that. We will continue to invest in additive manufacturing, and Sinterit will be a player in our industry.”

Expanding portfolio with new powder innovation

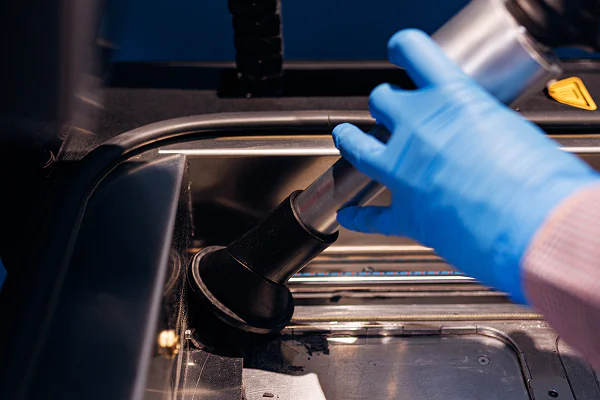

One of the highlights in our evolving portfolio is PA11.5 powder. Designed specifically for our Lisa X and Suzy printers, this powder makes it possible to create highly complex nylon parts that combine dimensional accuracy, strength, and flexibility. Even better, Sinterit PA11.5 is priced far below any other PA11 powder currently available in the industry.

Even though PA11.5 has only just entered the market, we want to share an interesting case study showing its impact. This story demonstrates how the implementation of PA11.5 powder and the SUZY printer in the production process can be highly cost-effective. We invite you to read the full story here.

As our CFO Łukasz Adach explained: “There is only one success factor in today’s selective sintering market: You have to offer the lowest cost for a specific manufacturing application. The time where you could sell a machine and the customer would figure out what to do with it is over. As are the times, where success meant that you managed to make something, no matter what the cost. Cost of parts is the overriding criteria for people to move to additive manufacturing.”

SLS technology poised for next stage

While filament-based printers remain the go-to choice for many applications, we see strong demand for SLS in areas requiring intricate geometries and superior surface quality.

Adach added: “In most cases now customers choose filament based printers for all the right reasons, but where intricate shapes with high surface specifications are required, SLS cannot be beaten. Sinterit will continue to offer customers the best cost and quality in the industry. This cannot be achieved just with printer technology, AI and specific powders will play an increasing role in the future. Sinterit is prepared for this.”

With bold steps on both the business and product side, we’re showing that we don’t just plan to ride out the current market challenges — we’re here to actively shape the future of additive manufacturing.