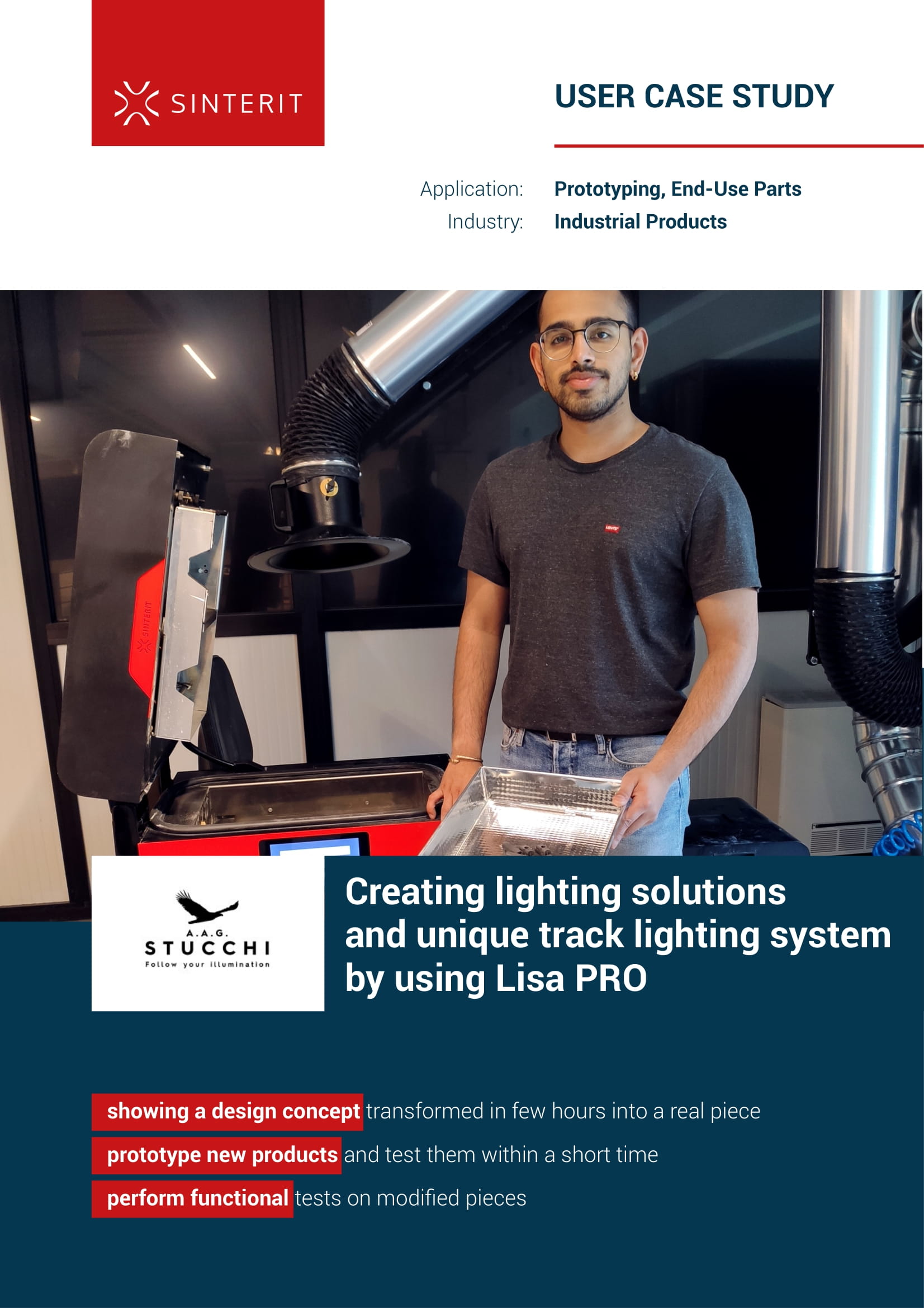

Creating lighting solutions and unique track lighting system by using Lisa PRO

- showing a design concept showing a design concept transformed in few hours into a real piece

- prototype new products prototype new products and test them within a short time

- perform functional perform functional tests on modified pieces

Background

A.A.G. Stucchi has been an active leader in the field of lighting for more than 70 years, producing “Made in Italy” quality components. They have evolved from being a component supplier to a reliable partner in creating lighting solutions.

LED technology presented Stucchi with a real challenge. They have faced head-on by expanding their product range without changing their core business. A.A.G. Stucchi systems for track lighting, ONETRACK, and MULTISYSTEM, are the best examples of this approach.

Their success enabled them to expand abroad. They now have three subsidiaries and 80 specialized distributors all over the world.

Learn more

Why Lisa PRO is perfect for prototyping

Problem

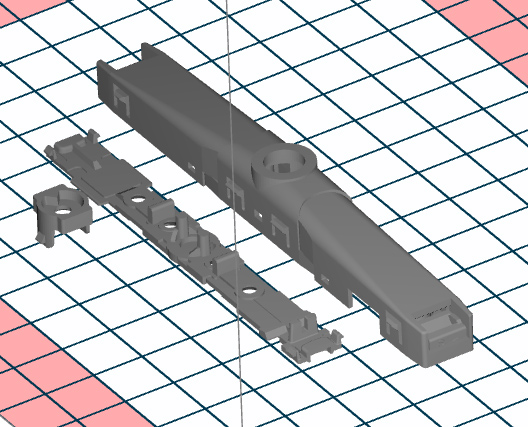

Fast prototyping has been a critical factor to reduce the time of product development. They used to have a couple of suppliers for 3D printing, but they needed more efficiency. They design products and molds internally, so the opportunity to have a real piece even in an early stage of the project is beneficial. Showing the customers a design concept transformed in a few hours into a real piece has changed their approach to projects.

In the past, they would have to manually modify the pieces to simulate the modification, but it was not possible in some cases, or the result was not realistic. If in a hurry, they would modify the molds step by step until reaching the final result.

Solution

A.A.G. Stucchi looked for a solution that would avoid the construction of molds until the final version of the new project. After getting acquainted with the offer, they decided to purchase the SLS Sinterit Lisa PRO 3D printer.

With 3D printing technology, they can prototype new products and test them in a short time. When they are 100% satisfied, they can build the mold. Even if they do their best to freeze product

specifications at the beginning of the project, a change request can also occur when the molds are already prepared. In this case, the cost of modification increases a lot, so with the Lisa PRO printer, they can perform functional tests on modified pieces before the transformation on molds becomes effective.

A.A.G. Stucchi creates a unique track lighting system to give the best solution to their customers. In their case, the Lisa PRO printer is essential during the design, but with the advancement of 3D printing technology, it could replace the injection molding technique.

Visit our customer’s website:

- showing a design concept transformed in few hours into a real piece

- prototype new products prototype new products and test them within a short time

- perform functional perform functional tests on modified pieces