3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

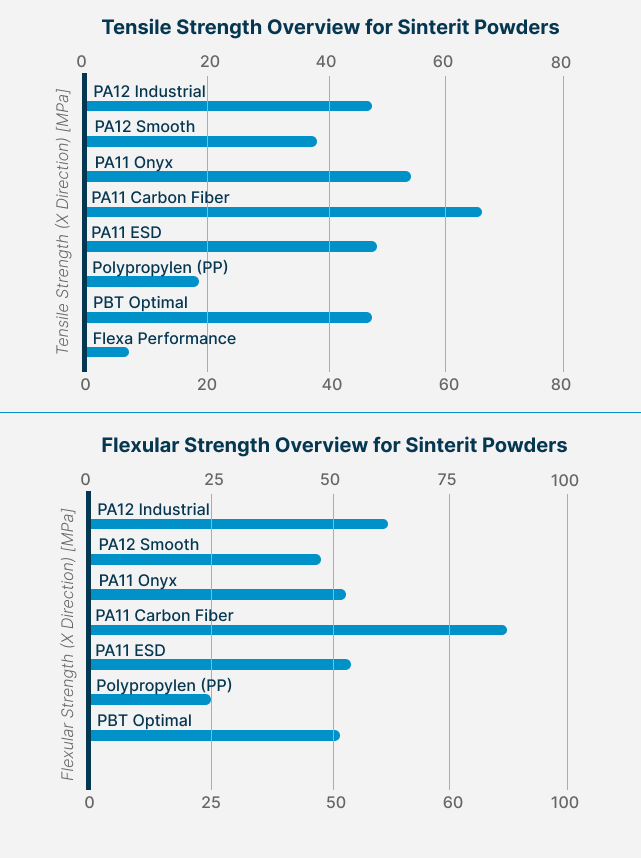

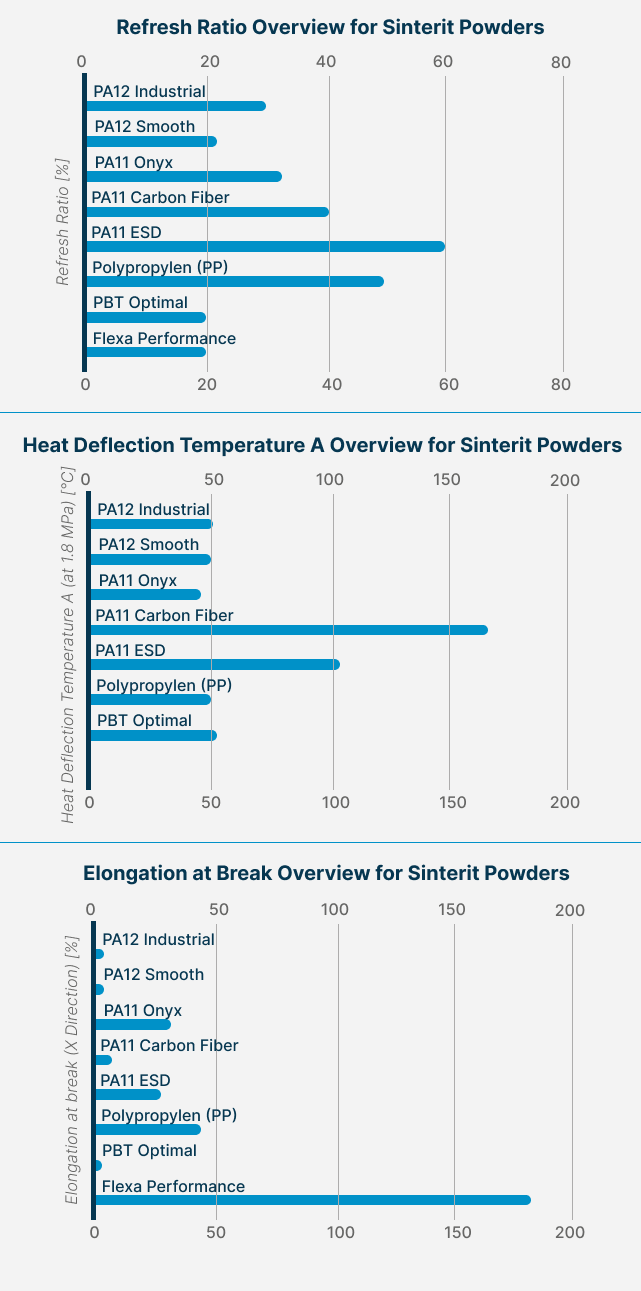

| Powder | Tensile Strength (X) [MPa] | Flexural Strength (X) [MPa] | Elongation at Break (X) [%] | Heat Deflection Temp A (1.8 MPa) [°C] | Refresh Ratio [%] |

|---|---|---|---|---|---|

| PA12 Industrial | 47.61 | 62.31 | 5.86 | 51 | 30 |

| PA12 Smooth | 38.44 | 49.18 | 4.55 | 50 | 22 |

| PA11 Onyx | 55.00 | 54.20 | 31.60 | 47 | 33 |

| PA11 Carbon Fiber | 65.93 | 87.35 | 8.23 | 167 | 40 |

| PA11 ESD | 50.00 | 56.00 | 28.00 | 103 | 60 |

| Polypropylen (PP) | 19.30 | 25.60 | 44.40 | 50 | 50 |

| PBT Optimal | 49.04 | 52.08 | 2.56 | 52 | 20 |

| Flexa Performance | 7.99 | – | 182.63 | – | 20 |

1. Tensile Strength

Indicates the maximum stress a material can withstand when stretched before breaking. For the user, this shows how resistant to pulling or tension the printed part will be – crucial for clips, housings, and structural elements.

2. Flexural Strength

Measures how much bending force a material can handle before failing. Important for slender or beam-like parts that may be bent or flexed in use.

3. Elongation at Break

Tells you how much the material can stretch before it breaks – a measure of flexibility or ductility. A high value = flexible and impact-resistant parts. A low value = stiff and brittle.

4. Heat Deflection Temperature A (HDT A)

This shows the temperature at which a material starts to deform under pressure. High HDT means the part is suitable for high-temperature environments, such as engine compartments or electronic housings.

5. Refresh-Rate

Describes how much fresh powder needs to be added to used material to maintain print quality. Lower values = more cost-effective and sustainable powder usage.

PA12 Industrial

Well-balanced mechanical performance. Great strength and moderate flexibility.

Best for: functional prototypes, mechanical parts, everyday engineering applications.

PA12 Smooth

Slightly lower strength than Industrial, but with a lower refresh ratio. Great value for budget-conscious users.

Best for: concept models, parts with fine surface details, general prototyping.

PA11 Onyx

High flexibility (31.6%) with solid strength.

Strong but more forgiving than rigid fibers.

Best for: snap fits, live hinges, parts requiring impact resistance.

PA11 Carbon Fiber

Top performer in all mechanical and thermal categories.

Stiff, heat-resistant, and durable.

Best for: end-use parts in engineering, automotive, motorsports, and industrial settings.

PA11 ESD

Balanced strength and high flexibility, plus ESD protection.

Best for: electronic casings, enclosures, and ESD-safe tooling.

Polypropylene (PP)

Lower strength, but very flexible and chemically resistant.

Best for: lightweight, chemical-exposed parts like tanks, tubes, or lab tools.

PBT Optimal

Rigid and precise, with low ductility.

Best refresh ratio = economical for low packing density prints.

Best for: technical precision parts, clips, electrical connectors.

Flexa Performance

Ultra-flexible, stretchable, and durable.

Best for: seals, dampers, soft mechanisms, cushioning components.

Tensile Strength

PA11 Carbon Fiber (65.93 MPa) ➡

Offers the highest resistance to pulling forces – ideal for structural, load-bearing components.

Flexural Strength

PA11 Carbon Fiber (87.35 MPa) ➡

Delivers excellent resistance to bending – perfect for parts like brackets, frames, and housings.

Elongation at Break

Flexa Performance (182.63%) ➡

Extremely flexible – recommended for hinges, seals, and impact-absorbing elements. At the other end of the spectrum, PBT Optimal (2.56%) ➡ Remarkable stiffness for all applications requiring high rigidity.

Heat Deflection Temperature A (HDT A)

PA11 Carbon Fiber (167 °C) ➡

Withstands high temperatures – great for technical or automotive applications.

Refresh Ratio

PBT Optimal (20%) ➡

Most cost-efficient in powder reuse – ideal for economical prototyping workflows.