3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

SLS 3D printing for research

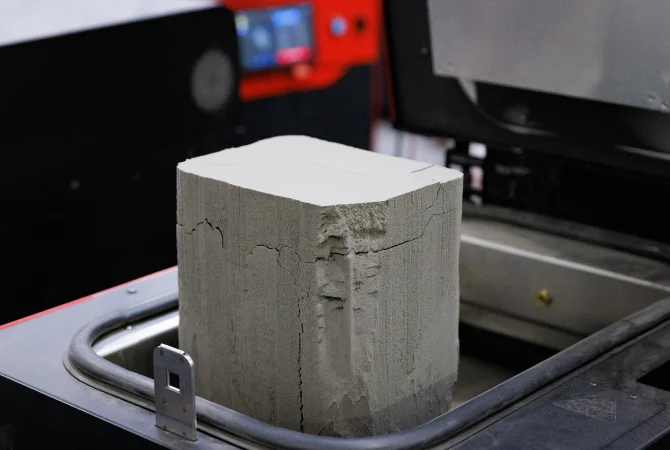

No support structures

The freedom of creation is especially important for education and research. SLS technology allows for functional complex designs, without the need for support structures. Movable parts operate correctly, and intricate internal structures are achievable, eliminating the need for post-processing that could disrupt dimensions or surface quality.

Adjustable powder volume

With adjustable powder volume, you can tailor the amount of powder to match your model’s height, eliminating the need to fill the entire bed. This flexibility allows you to start with as little as 0.5 kg of material, optimizing resource use and reducing waste while enhancing research and prototyping.

Easy materials switch

Typical SLS systems lock users into a one printer = one material framework. If you need to use multiple materials, you face two choices:

Sinterit offers a better solution. Our system enables fast material changes between jobs and allows you to bypass certain steps for less frequently used powders.

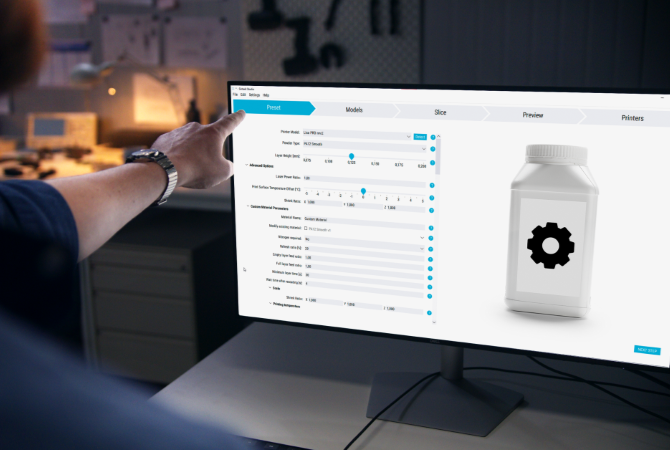

Open parameters

Sinterit’s solution provides precise control with 32 adjustable printing parameters. This feature allows users to fine-tune the printing process to meet their specific needs. Whether you’re using a custom material or modifying profiles for Sinterit’s materials, these parameters let you adjust the mechanical, functional, and aesthetic properties of your prints. Save and reuse your custom profiles for consistent results every time.

3rd party materials

The Lisa X SLS 3D printer supports third-party materials and custom material development. This flexibility enables users to create tailored material profiles for specific applications, ensuring optimal performance and expanding the range of possible projects. Whether using ready-made material profiles or experimenting with new ones, the Lisa X adapts to your needs.

The printing process is not complicated and can be learned in a short time even by staff members with no 3D printing experience. We offer 5-hour online training split into 2 sessions (basic + advanced, 2 weeks apart) as a part of the premium service plan.

The exact printing speed is dependent on a couple of factors, like layer height and build pack density. In almost all cases the whole process of printing, cooling, and post-processing takes up less than 24 hours, so you should be able to produce at least 5 full print beds per workweek.