Before you start printing with a SLS 3D printer: 3D printer health and safety, 3D software

When it comes to setting up your SLS printer, safety should be your number one concern. Whether you’re a first-time user or an experienced operator, following the right safety procedures is essential for protecting both people and equipment. From handling fine powders and ensuring proper ventilation to preparing for high temperatures and electrical risks, every step in the setup process matters.

In this post, we’ll guide you through the core safety rules for working with SLS 3D printers and highlight why understanding the software — like Sinterit Studio — is equally important. With the right knowledge and preparation, you’ll create a safer, more efficient workflow and achieve better printing results.

3D printer safety rules

Start off by gearing up with the right protective equipment like gloves, dust masks, and safety glasses to shield yourself from powders and fumes. Handling materials carefully is key to steering clear of any health hazards, especially with fine powders that can be risky if inhaled. To safeguard your surroundings, make sure to use a vacuum system specifically designed for fine dust, as SLS printing materials carry a potential explosion risk. It’s crucial to work in a well-ventilated space, preferably with a good ventilation system to reduce the inhalation of fumes and airborne particles.

Given the high temperatures involved in SLS printing, it’s a smart move to have a fire extinguisher nearby, just in case things heat up. Ensure all electrical connections are properly grounded for safety, and put anti-static measures in place to prevent any damaging static discharge on the printer or other equipment.

Don’t forget about ergonomics – setting up your printer and equipment at comfortable heights can ease strain on your team and boost workspace efficiency. Keep the area tidy and organized to steer clear of any accidents or trip hazards.

Lastly, familiarize yourself with industry-specific safety rules and ensure everyone involved in the installation process is well-trained in proper handling procedures. Being prepared for emergencies and upholding safety measures will help ensure a smooth and secure installation process.

More on safety with Sinterit you’ll find on our blog: Safety in SLS 3D printing.

Software & trainings

Before fulfilling any order using an SLS (Selective Laser Sintering) 3D printer, it is crucial to ensure that the operator is fully familiar with the software ecosystem and receives proper training if needed. This is particularly important when working with professional systems.

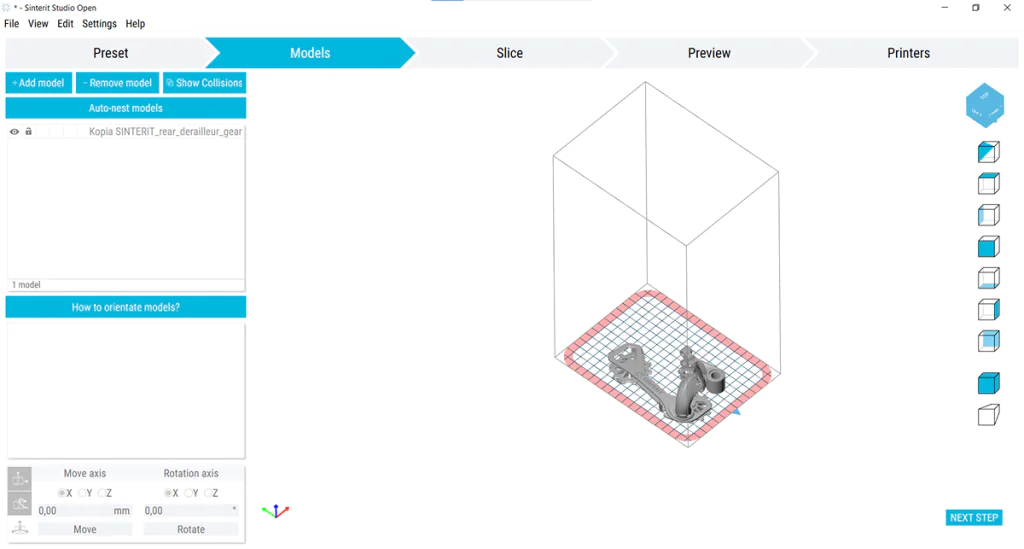

Sinterit’s workflow is powered by its proprietary software, Sinterit Studio, which plays a central role in the printing process – from preparing and slicing 3D models to setting advanced printing parameters and managing print jobs. While the software is designed to be intuitive, in both basic and advanced mode, it also offers a range of advanced settings that allow experienced users to optimize print quality, mechanical properties, and material usage.

Familiarity with Sinterit Studio is essential not just for loading and slicing models, but also for understanding part orientation, powder distribution, support-free design optimization, and post-processing steps. Mistakes in the setup phase can result in failed prints, increased material waste, or mechanical issues in the final parts. That’s why manufacturers also provide comprehensive training programs – both in-person and online – to ensure users can confidently operate their systems. These training sessions cover everything from unpacking the printer and performing calibrations to troubleshooting and maintaining consistent print quality over time.

In short, before committing to customer orders, any operator working with an SLS system – should prioritize gaining hands-on experience with the software and ensure all involved personnel are properly trained. This not only protects your investment and ensures product reliability but also maximizes the printer’s potential and enhances customer satisfaction.

Quick Q&A summary

What safety steps should be taken before installation?

Use appropriate personal protective equipment like gloves, dust masks, and safety glasses, especially when handling powders. Set up good ventilation, have a dust-rated vacuum system available, ensure proper grounding for electrical connections, and install anti-static measures.

Are 3D printers safe to use indoors?

Yes, they are safe if used correctly. Ensure proper ventilation, use protective gear for resins or powders, and follow manufacturer guidelines. Different printer types (FDM, SLA, SLS) have different safety needs.

Are there specific health risks of 3D printing SLS I should be aware of?

Yes – SLS printing involves high temperatures and laser radiation, so it’s important to follow laser safety standards, mark the workspace properly, and limit access to trained personnel. Powders used in SLS are also flammable and potentially hazardous if inhaled, so proper storage, handling, and workspace cleanliness are crucial.

Why is it important to understand the software and receive training before fulfilling orders with an SLS 3D printer?

To ensure reliable print quality and avoid costly errors. The software controls aspects like model preparation, print settings, and job management. Without proper knowledge, mistakes in setup can lead to failed prints, material waste, and delays. Training helps operators confidently handle the full workflow, ensuring efficient and successful production.

Learn more what to prepare before the SLS printer installation.