Industry 4.0 with Lisa X

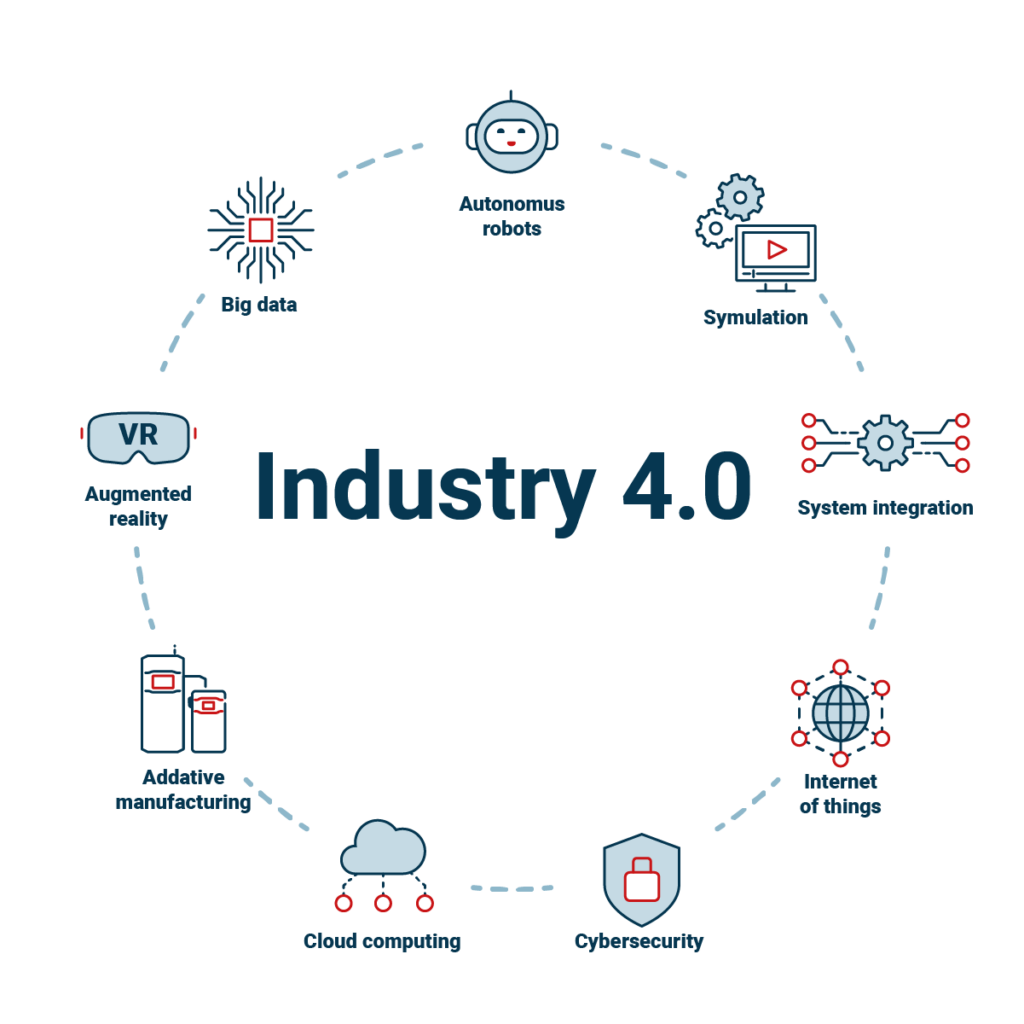

Industry 4.0, also known as the Fourth Industrial Revolution, represents a significant transformation in the way industries and businesses operate. It is characterized by the integration of digital technologies, data, and automation into various aspects of manufacturing and production processes. What are the substantial benefits and advancements of Industry 4.0? How does it change the additive manufacturing industry? Let’s find out.

10 benefits of industry 4.0

Industry 4.0 represents smart, connected manufacturing system designed to report, predict and detect potential problems. The main reason companies should consider its implementation is to increase productivity, energy efficiency, safety of the employees and production. Below you can find ten reasons why industry 4.0 can help you make better decisions that support your production in real time.

Increased Efficiency

Industry 4.0 technologies such as IoT (Internet of Things), big data analytics, and automation can optimize production processes, reduce waste, and enhance overall operational efficiency. Those benefits are well known for additive manufacturing users who as well choose 3D printing technology for optimizing processes and waste reduction.

Cost Reduction

There are many tasks across various companies that are repetitive and can be easily automated. Industry 4.0 is the way for optimizing resource usage, companies can reduce labor costs and operational expenses.

Quality Improvement

One of the goals of implementing 3D printing in the company is to speed up prototyping time which results in achieving better quality in given time. Real-time data monitoring and analytics enable better quality control, reducing defects and ensuring higher product quality.

Innovation

Industry 4.0 encourages innovation by fostering the development of new products, services, and business models. Companies can leverage data insights to create products tailored to customer preferences.

Supply Chain Optimization

Improved data sharing and visibility across the supply chain lead to better inventory management, demand forecasting, and logistics optimization.

Customization

Industry 4.0 technologies allow for greater customization of products, meeting individual customer needs more effectively.

Competitive Advantage

Companies that adopt Industry 4.0 practices can gain a competitive edge by responding faster to market changes and customer demands.

Sustainability

Enhanced resource management and reduced waste contribute to more sustainable manufacturing practices, which are increasingly important in a world focused on environmental conservation.

Global Connectivity

Industry 4.0 promotes global connectivity and collaboration among businesses, allowing for the exchange of knowledge and best practices.

Customer Satisfaction

With the ability to offer personalized products and quicker response times, companies can enhance customer satisfaction and loyalty.

Industry 4.0 in AM projects

3D printing is by design very close to the prerogatives of industry 4.0 but there is still enough space for improvements. Why should you consider implementing industry 4.0 in your additive manufacturing projects?

First of all, it will allow you to fully integrate 3D printing with your company structure. It will give you a better understanding of the whole manufacturing process. It goes hand in hand with achieving full transparency. With industry 4.0 implemented in your additive manufacturing projects you can predict maintenance needs and proceed with them smoothly. It also brings cost reduction through better use of equipment and optimization of production batches in your machine park.

Sinterit’s R&D team developed an API which makes Lisa X ready for industry 4.0 integration. The printer shares data with your production system thanks to two-way communication.

API allows queuing of printouts, so you can add more print jobs to the printer. There is also a possibility to live monitor 20 most important operational and security parameters. For security reasons, printing starts manually.

With Lisa X industry 4.0 ready SLS 3D printer you get higher performance with better use of resources and fewer quality problems due to faster response to potential process disruption. Optimizing schedules results in faster production, and with reduced handling costs it becomes an even more desirable solution. Not to mention, that for users residing in EU countries it is also possible to apply for Industry 4.0 subventions.