How to expedite research and development of new products?

- showing a design concept transformed in few hours into a real piece

- prototype new products and test them within a short time

- perform functional tests on modified pieces

Background

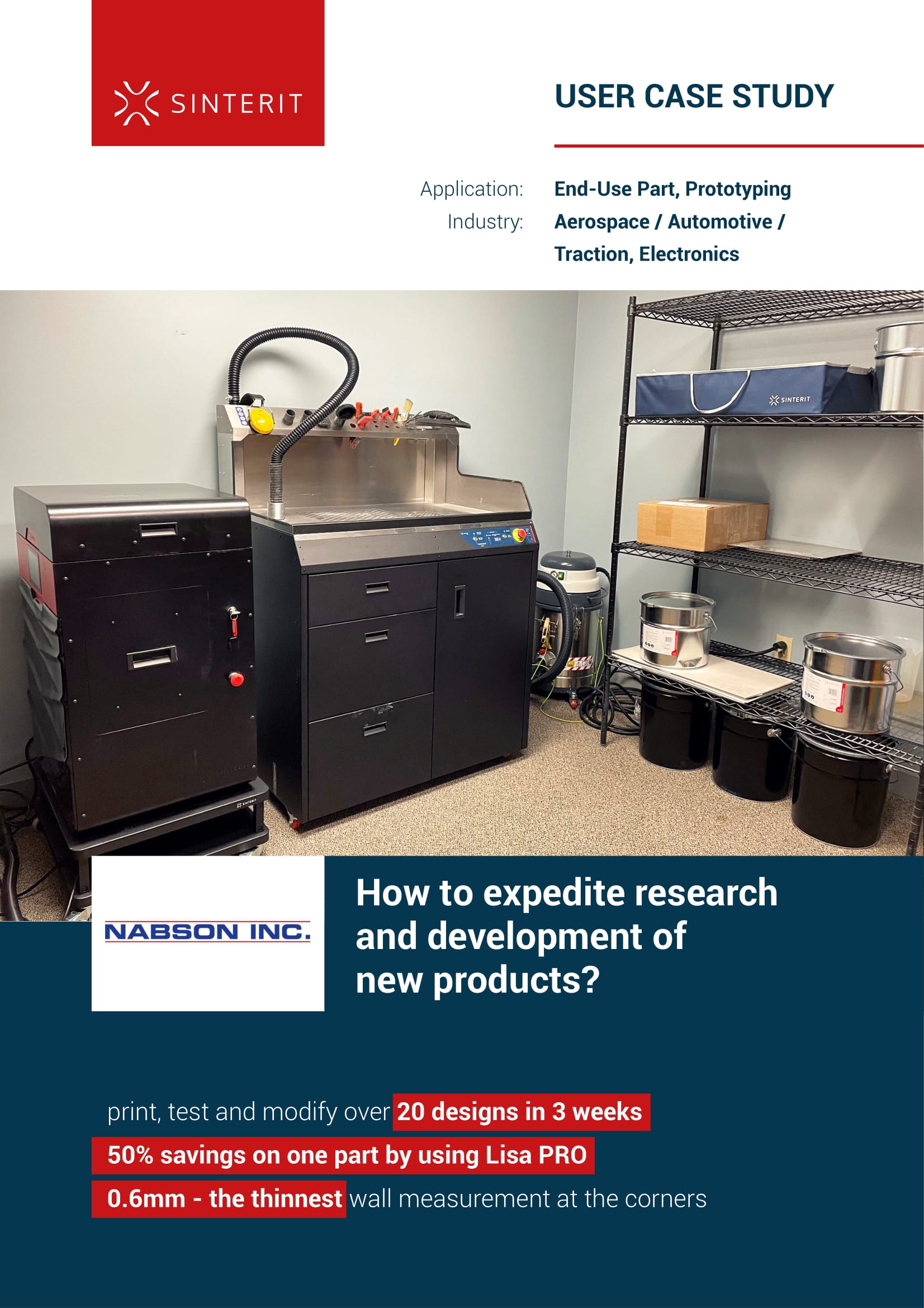

Nabson’s largest business operation is manufacturing ground power cable assemblies and connectors for the commercial and defense aviation industry.

In early 2019, Nabson purchased a dual-head FDM 3D printer to expedite research and development of new products and the development of one of its product lines.

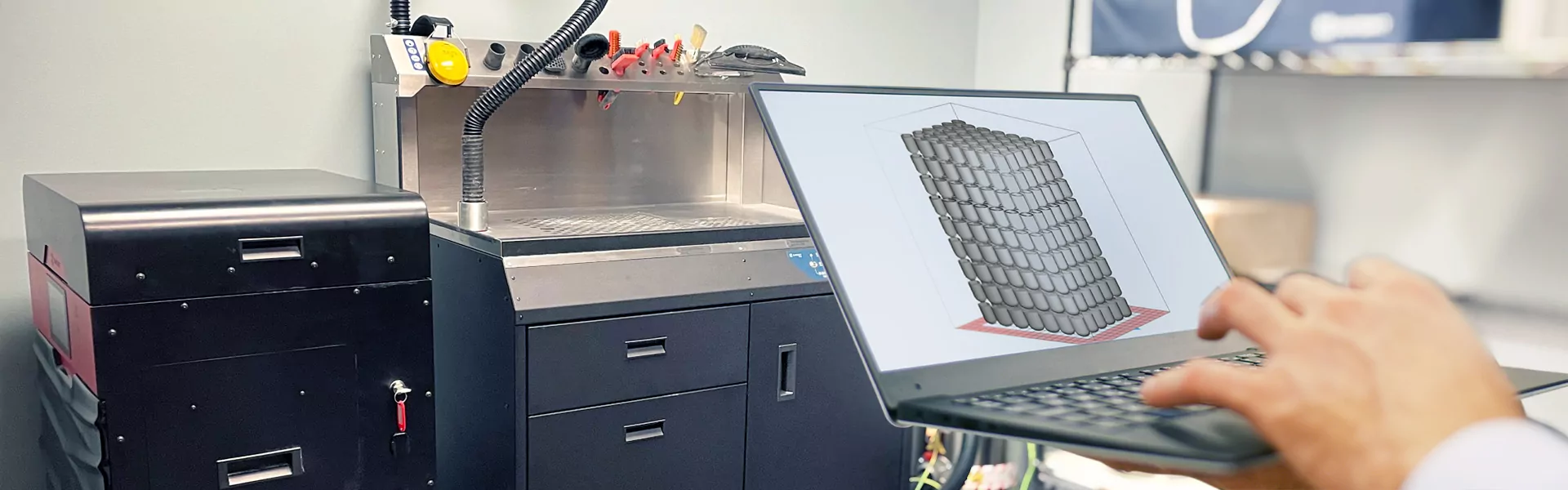

Based on the success of the FDM printer, in late 2019, Nabson looked to expand their 3D printing capability with an SLS printer that could produce small run parts and prototypes with better accuracy. After conducting extensive market research they selected the Lisa PRO to balance cost and capabilities. Sean Higgins, the manager of Organizational Effectiveness, explained how the LISA PRO has helped the business in 2020.

Learn more

Why Lisa PRO is perfect for prototyping?

Problem

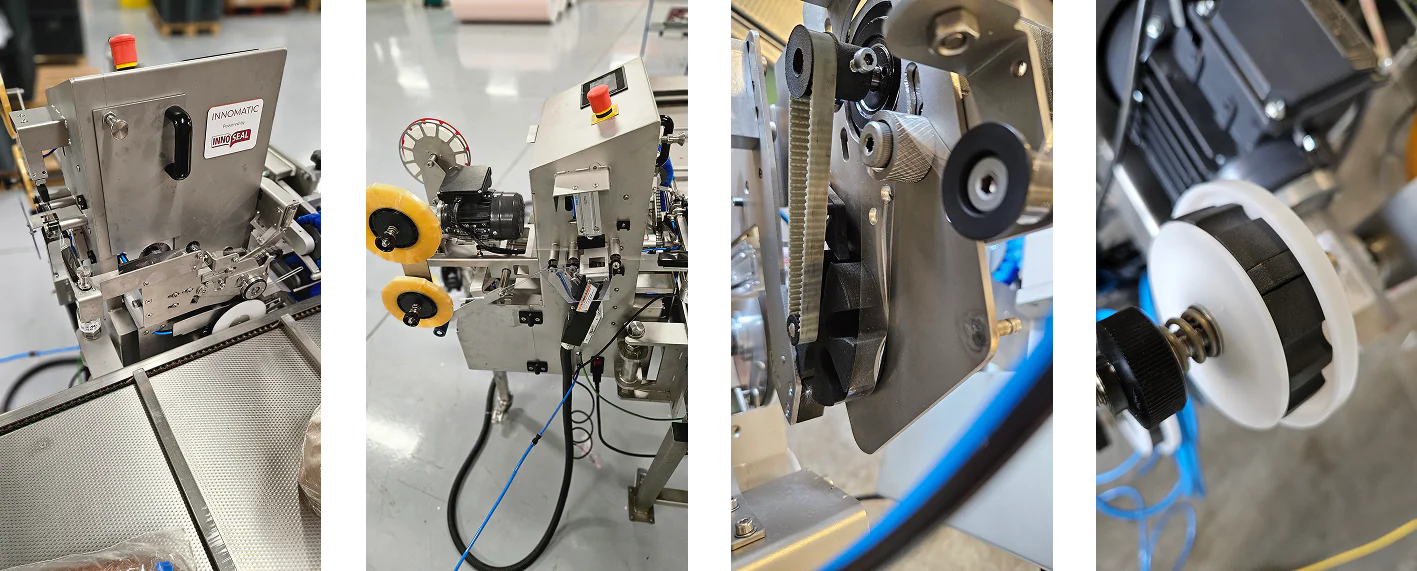

To increase safety in a specific product line Nabson was asked to install a series of thermal switches that shut down power to the aircraft if the connector overheats.

There were two issues that they had to resolve:

– The amount of free space in the rubber over-molded connector is severely limited;

– The thermal switches had to be encased in epoxy to protect them from the pressure exerted on the switches during the rubber injection process.

They tasked their Engineer, to work with their assembly team and develop a housing unit that when filled with epoxy, would protect the thermal switch during the injection process and allow sufficient heat transfer to the switch itself.

Solution

“In a three-week period, we were able to print, test, and modify over 20 designs.”

Because of the part size, they decided to use the Lisa PRO and manufacture the part in-house as outsourcing costs were estimated at $2.28 per sleeve in quantities of 1000. Although they do not have an exact cost, they estimated that they are saving almost 50% per sleeve and have the option to modify the design (which they have done twice) since October.

The Lisa PRO provided the accuracy we required, over an FDM, as the thinnest wall measurement at the corners was 0.6mm. The workflow allowed us to print three to four designs overnight, fill them with epoxy, and test for results the same day.

“In order to keep up with our production demand, we have been operating the Lisa PRO almost 7 days a week for the past couple of months, without incident, and produced over 1500 sleeves.”

Visit our customer’s website:

- showing a design concept transformed in few hours into a real piece

- prototype new products and test them within a short time

- perform functional tests on modified pieces

Austria

Austria  Bosnia and Herzegovina

Bosnia and Herzegovina  Bulgaria

Bulgaria  Croatia

Croatia  Czech Republic

Czech Republic  Denmark

Denmark  Estonia

Estonia  Finland

Finland  France

France  Germany

Germany  Greece

Greece  Hungary

Hungary  Ireland

Ireland  Italy

Italy  Latvia

Latvia  Lithuania

Lithuania  Poland

Poland  Portugal

Portugal  Romania

Romania  Slovakia

Slovakia  Slovenia

Slovenia  Spain

Spain  Sweden

Sweden  Switzerland

Switzerland  United Kingdom

United Kingdom  Ukraine

Ukraine  China

China  Hong Kong

Hong Kong  India

India  Israel

Israel  Japan

Japan  Malaysia

Malaysia  Philippines

Philippines  Saudi Arabia

Saudi Arabia  South Korea

South Korea  Taiwan

Taiwan  Thailand

Thailand  Turkey

Turkey  United Arab Emirates

United Arab Emirates  Egypt

Egypt  South Africa

South Africa  Tunisia

Tunisia  Canada

Canada  Mexico

Mexico  United States

United States  Brasil

Brasil  Colombia

Colombia  Australia

Australia  New Zealand

New Zealand