3D printing in medical industry

3D printing in the medical industry is no longer a future concept — it’s an essential tool that’s actively reshaping modern healthcare. From surgical planning and patient-specific implants to drug development and dental applications, the use of 3D printing in medicine brings new levels of personalization, speed, and precision that traditional manufacturing simply can’t offer.

Let’s explore how this technology is changing the landscape of clinical care, biomedical engineering, and medical research.

What is 3D printing in medicine?

3D printing in medicine refers to the process of creating physical, medical-grade objects directly from digital models using additive manufacturing. These objects can include anatomical models, surgical tools, dental devices, orthotic supports, or even implantable components.

Because parts are made layer by layer, they can be tailored to an individual patient’s anatomy with unprecedented accuracy — a concept known as patient-specific or personalized healthcare.

How is 3D printing used in medicine?

The medical use of 3D printing spans a wide range of disciplines and applications. Some of the most impactful areas include:

- surgical planning – 3D printed anatomical models from CT or MRI data help surgeons rehearse complex procedures before entering the operating room,

- custom implants and prosthetics – devices such as cranial plates, dental implants, and limb prosthetics can be printed to match individual patient anatomy,

- medical tools and guides – drill guides, positioning templates, and surgical instruments are made faster and more accurately with 3D printing,

- tissue engineering research – experimental bioprinting uses living cells and scaffolds to explore regenerative applications.

In short, 3D printing in medical technology offers a powerful toolkit to improve outcomes, reduce surgery times, and enable new treatment approaches.

3D printing in medical devices

Additive manufacturing is widely used in the design and production of medical devices, particularly for low-volume, high-complexity parts where traditional methods fall short. These include:

- orthopedic implants,

- spinal cages,

- patient-matched surgical tools,

- hearing aids,

- dental surgical guides and models.

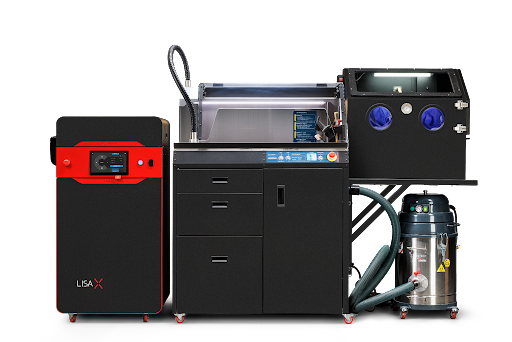

Because many of these products require biocompatibility and sterilization, material selection and process validation are critical. Technologies like SLS (for PA12), SLA (for Class I resins), and metal printing (for titanium) all play a role depending on the application.

Use of 3D printing in healthcare and pharmaceuticals

Beyond devices, 3D printing is influencing the broader healthcare and pharmaceutical sectors. In clinical education, lifelike printed models help train medical students and prepare surgeons for rare or difficult procedures. In diagnostics, labs are using 3D printed tools and platforms to miniaturize testing and reduce cost. In pharmaceuticals, researchers are exploring on-demand manufacturing of personalized pills with layered drug-release profiles. This approach could eventually support tailored therapies for individual patients — one of the most promising frontiers in medical science and pharmaceutical innovation.

Benefits of 3D printing in medicine

The benefits of 3D printing in medicine are numerous and growing. Key advantages include:

- customization – parts can be made to match the patient’s exact anatomy,

- speed – surgical models or guides can be produced in a matter of hours,

- cost-effectiveness – reduced need for inventory or custom tooling,

- minimally invasive solutions – improved surgical planning and fit mean shorter procedures and faster recovery,

- innovation – enables research and development of treatments that were previously unfeasible.

It’s important to know that 3D printing for medical purposes is one of the most dynamic and impactful applications of additive manufacturing. From enhancing surgical precision to enabling next-generation pharmaceuticals, it represents a shift toward more intelligent, adaptable, and patient-centered healthcare.

As the technology continues to mature, the question isn’t just how can 3D printing be used in medicine — it’s how soon it will become the standard of care.

Explore also

Related categories