How to bring products to the market sooner?

- showing a design concept 3x faster product implementation time

- prototype new products £30,000 savings on a project that would cost £50,000

- perform functional 223 parts printed in 1 print

Background

Rotite is an innovative low profile, high strength, polymer fastening technology used in various applications (e.g., hermetic USB connectors, strap fastenings for baby seats to composite panel fastening in the automotive sector). It features a unique patented geometry that is logical and easy to use. Rotite can be integrated into many products and therefore manufactured in many ways but is unmatched when partnered with the design freedom of SLS.

Rotite integrates its technology into other companies’ products, which saves them time, space, weight, and ultimately cost. More recently, they have created their own brand Spyn, designing and delivering their own end-use products for consumer use.

Learn more

Why Lisa PRO is ideal for designing prototypes

Problem

As an agile business, development time and time to market are critical in developing their products. Furthermore, the cost of tooling to produce parts can be prohibitively expensive for their Lean balance sheet. The geometry of their Patented technology requires careful planning and expensive specialized tooling to manufacture using injection molding. Other methods of manufacture have substantial price barriers.

Solution

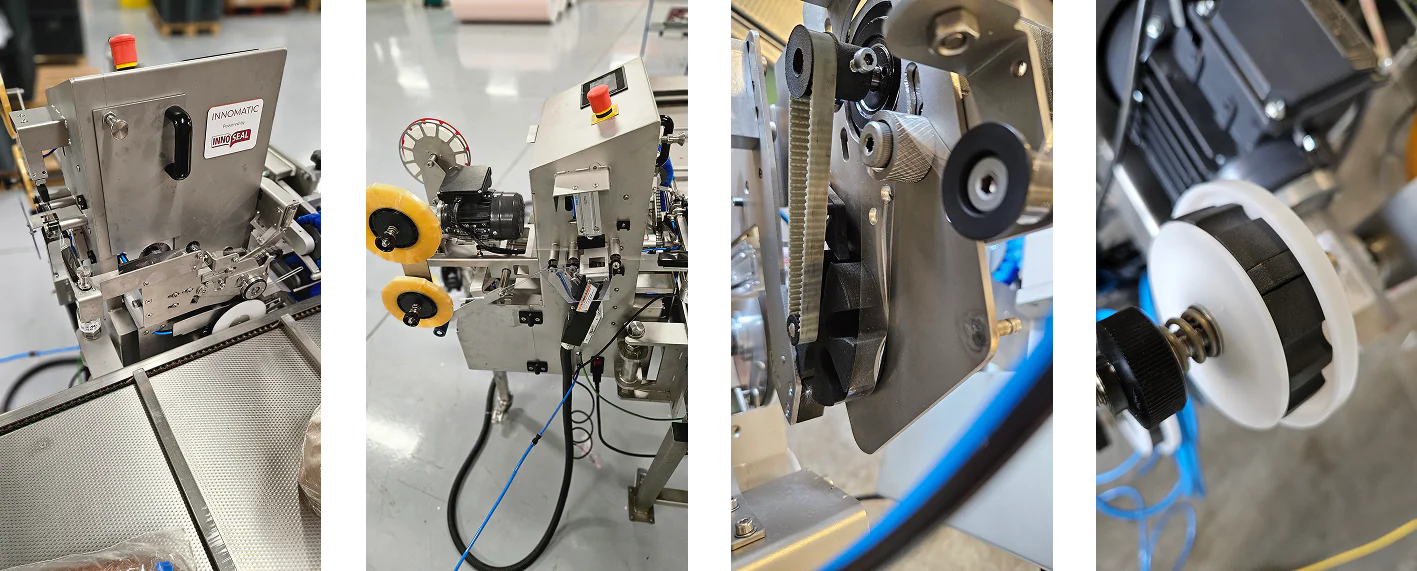

During the proof-of-concept stage, Rotite initially had its designs manufactured by a 3D print service provider on an MJF machine. As the project developed, Rotite won government funding for innovation and directed the funds to purchase a Sinterit Lisa PRO.

Now with the ability to print in-house, they can manage the whole process internally – conception, design, development, and production can take place in their own office space. It gives £30,000 savings on a project that would cost us £50,000. This is based upon the cost of getting injection molding tools for the parts minus the cost of the Sinterit equipment. As a lean operation, the ability to bring a product to market without investing in injection molding tooling has been critical to their success. Now they have 223 parts printed in 1 print.

Rotite is able to pivot on an idea, make changes to production, and add a broader range of products with essentially no sunk costs on redundant tooling. The professional quality and mechanical performance of Sinterit PA12 powder enable companies, like Rotite, to develop consumer products without the high entry costs associated with injection molding. By purchasing a Lisa PRO, they positioned themselves in a price range funded by innovation grants and was a key enabler to their business. Now, product implementation time is three times faster. They can develop and improve alongside production and sale.

Consequently, thanks to the Lisa PRO’S cost, efficiency, and flexibility benefits, the company has effectively been able to expedite its manufacturing workflow while creating end-use-ready products at a much higher standard than before.

Visit our customer’s website:

- showing a design concept 3x faster product implementation time

- prototype new products £30,000 savings on a project that would cost £50,000

- perform functional 223 parts printed in 1 print