3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

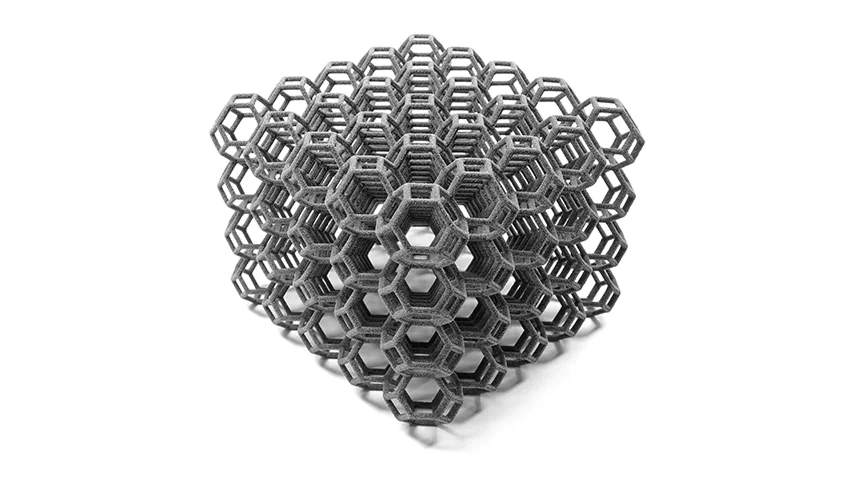

Print without design limitations

SLS lets researchers create highly complex geometries — including internal channels, lattices, or moving parts — without support structures. This opens up possibilities for experimental models, functional mechanisms, and form-factor validation that FDM or SLA simply can’t handle.

Reliable mechanical performance

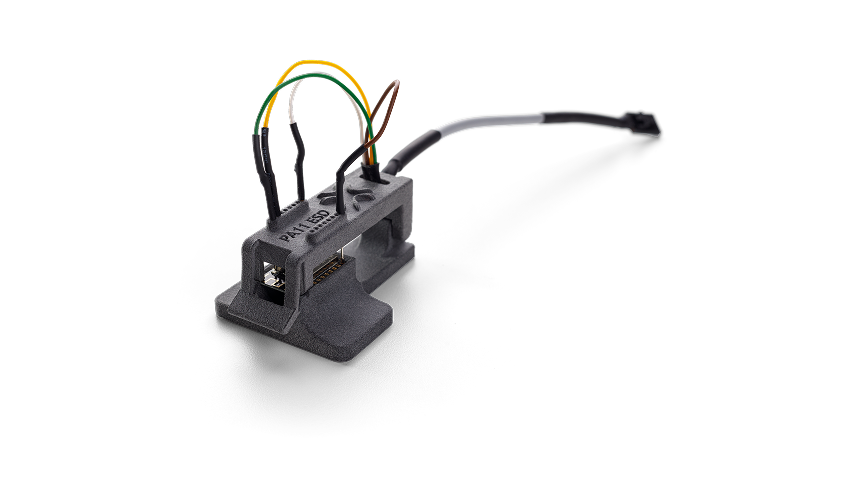

Sinterit printers use industrial-grade materials like PA12, PA11 Onyx, or PA 11.5, which offer excellent strength, temperature resistance, and durability. You can conduct real-world functional testing directly on printed parts, which is essential in engineering research or product feasibility studies.

Rapid, iterative development in-house

Researchers can go from CAD to the tested part in under 24 hours — enabling same-week validation of multiple hypotheses or design variants. No outsourcing, no waiting for suppliers. This dramatically improves feedback loops and accelerates experimentation cycles.

Adapted for lab environments

Sinterit systems are compact, accessible, and easy to integrate into research labs. With intuitive software, multi-material support, and no tooling requirements, they offer full control over prototyping and material studies — whether you’re exploring mechanical behavior or functional integration.

Trusted by research teams for structural testing, fit validation, and functional prototyping with excellent dimensional accuracy and mechanical reliability

Unlock full process control for experimental research, material testing, and sintering behavior exploration with customizable printing profiles

Research 3D printing refers to the use of additive manufacturing in scientific and engineering environments where experimentation, testing, and iteration are key. In this context, SLS allows researchers to move from digital concept to physical prototype quickly, reliably, and with full geometric freedom — enabling exploration and validation of ideas without reliance on tooling or external services.

A research material is typically used to test and evaluate behavior under controlled conditions. In additive manufacturing, this may include standard powders, modified formulations, or experimental blends analyzed for printability, sintering consistency, strength, or durability. With systems like Sinterit’s, researchers can adjust open parameters to suit specific experimental needs and gain deeper insight into material performance.

SLS technology offers exceptional stability and repeatability, making it ideal for studying powder behavior, thermal effects, and microstructure evolution. Its open parameters allow researchers to control the sintering process and tailor it to new materials or blends, while high-quality prints support precise post-analysis and mechanical validation.

SLS delivers mechanically strong, isotropic parts that require no support structures, making it more suitable for functional prototypes, test specimens, or integrated assemblies. Compared to FDM or SLA, it offers better surface quality, dimensional consistency, and design freedom, all of which are essential in research workflows focused on real-world validation.

Yes — one of the biggest advantages of SLS in R&D is the ability to print, test, and iterate within extremely short cycles. Teams can print multiple versions of a concept overnight, validate physical performance the next day, and adapt designs quickly — all without the delays or dependencies associated with outsourcing or tooling changes.

SLS is widely used in structural research, material development, functional testing, and integration studies. It supports applications in sectors such as medical devices, aerospace, robotics, and electronics — wherever physical testing, rapid iteration, or design freedom are important.

Absolutely. With Sinterit’s open parameters and stable thermal management, researchers can run controlled tests on new powders, evaluate powder reuse and sintering profiles, and generate accurate physical samples for tensile testing, microscopy, or process development. This flexibility makes it a valuable tool in any material science or process engineering lab.

Yes — SLS parts printed with materials like PA12 Industrial or PA11 Onyx offer real-world mechanical performance. This means they can be used not just for form or visual inspection, but also for fit testing, load-bearing scenarios, or endurance experiments, all of which are common in R&D environments.