3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

Outstanding Impact Resistance

With the highest impact strength among rigid polymers in our portfolio (excluding TPU), this material is built to handle sudden shocks, drops, and repeated mechanical stress without damage.

High Flexibility and Elongation

Elongation at break of up to 27% ensures that parts remain resilient, bending instead of breaking — ideal for orthopedic insoles, braces, and other applications requiring elasticity.

Excellent Durability

Strong mechanical properties guarantee reliable long-term performance, even in demanding environments where parts must last.

Smooth Surface Finish

Parts come out with a refined, even surface quality, reducing the need for heavy post-processing and making them ready for functional use straight from the printer.

Cost-Efficient Printing

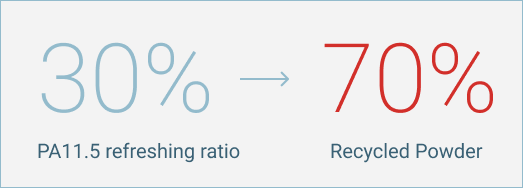

No nitrogen required and a refresh ratio of just 30% make it economical to use, keeping operational and material costs low.

Versatile Applications

From medical and footwear industries to consumer electronics and engineering, this powder adapts to a wide range of use cases — wherever strength and flexibility are equally important.

PA11.5 is designed for industries where durability, elasticity, and affordability are critical:

Medical & Orthopedics – orthopedic braces, orthoses, and insoles that must withstand repeated stress while ensuring patient comfort.

Footwear Industry – custom insoles and inserts combining long-term comfort, flexibility, and toughness. (See our case study with Fußorthopädie Paul Hast GmbH.)

Consumer Electronics – protective housings, covers, and enclosures where impact resistance extends product lifespan.

General Engineering – functional prototypes and end-use parts exposed to dynamic loads, requiring a balance of strength and resilience.

Whether you’re prototyping or moving into series production, PA11.5 gives you the freedom to design stronger, safer, and more resilient products—without overspending.

PA11.5 is a versatile SLS powder that combines outstanding impact resistance, high durability, and an excellent surface finish. Designed for robust, long-lasting applications, it gives engineers, designers, and manufacturers the freedom to create parts that don’t just look good—they perform reliably under real-world stress.

A X, PA11.5 expands your design possibilities with a smart balance of performance and cost-efficiency.

Curious how PA11.5 performs in real-world scenarios? Dive into our case study showing its use in producing orthopedic insoles with the SUZY printer.

You’ll discover how its unique combination of flexibility, impact resistance, and durability delivers superior comfort, resilience, and long-term performance in medical-grade applications.

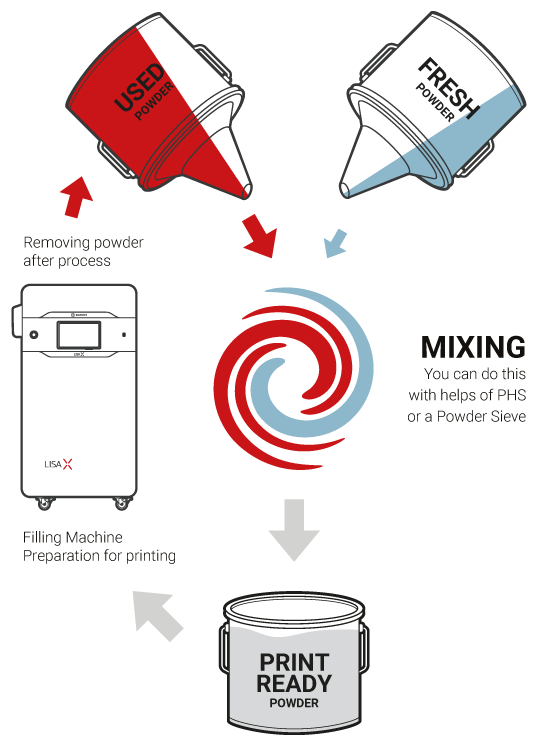

What is the refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.

How it works

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material.

To start SLS 3D printing you need the powder starter pack. After that, you’ll only need to refresh the powder you own with fresh powder.

PA11.5 offers the highest impact resistance of all our rigid polymers (excluding TPU). It combines toughness, flexibility, and affordability, making it a balanced choice for functional parts that must withstand dynamic loads.

Yes. PA11.5 is well suited for both rapid prototyping and durable end-use applications thanks to its strength, elasticity, and reliable long-term performance.

No. Unlike some demanding powders, PA11.5 does not require nitrogen, which makes the printing process simpler and more cost-efficient.

The refresh ratio is 30%. This means only 30% of new powder needs to be mixed with unsintered material, helping to keep material usage and overall printing costs low.

PA11.5 is widely used in medical and orthopedic applications (such as braces and insoles), footwear (custom inserts and insoles), consumer electronics (protective housings and covers), and general engineering where durability and flexibility are key.

Compared to PA12 Smooth, PA11.5 offers higher flexibility.

Compared to PA12 Industrial, it delivers superior impact resistance.

Compared to PA11 Onyx, it is a more economical and practical choice while still providing excellent toughness.

Yes. Its combination of high elongation and durability makes PA11.5 ideal for medical devices that need to withstand repeated stress while remaining comfortable for the user.

PA11.5 provides a smooth surface finish that reduces the need for intensive post-processing. Parts come out with an even, professional look suitable for functional use.

PA11.5 is available for both SUZY and LISA X printers. It delivers reliable performance on both platforms, giving SUZY users access to a flexible, impact-resistant material and offering LISA X users a cost-efficient, versatile option for professional workflows.

PA11.5 parts can be easily polished, dyed, or coated, allowing you to achieve the desired look and finish. Its smooth surface quality ensures excellent results with standard SLS post-processing techniques.