3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

An SLS system finally accessible to students

Most universities can’t afford to give students real hands-on time with powder-bed systems. Sinterit solves this with a compact, easy-to-use SLS printer that’s designed to run safely and independently in teaching labs — without needing a dedicated operator or technician.

No more fear of industrial machines

While some institutions own large-format additive systems, students rarely interact with them due to safety restrictions, scale, or complexity. Sinterit makes SLS approachable and manageable, so learners can take full ownership of the print process — from design to finished part.

Teach true SLS workflows, not simulations

Unlike FDM or SLA, Sinterit enables students to understand and apply powder-based additive manufacturing as it’s used in real R&D and production environments. They gain experience with real sintering, material handling, nesting strategies, and post-processing — not just a simplified analogy.

Designed for education, used in industry

Sinterit printers bridge the gap between education and application. They’re used by leading universities and R&D labs worldwide, giving students access to the same tools they’ll encounter in engineering jobs — but in a format that supports learning, not just output.

A go-to material for mechanical and structural exercises, ideal for teaching load-bearing design and functional prototyping

Perfect for visual design and presentation tasks, helping students evaluate surface quality, aesthetics, and dimensional accuracy

Used in impact or endurance testing, this material supports hands-on validation of strength-critical applications in student research

Yes. Sinterit printers are fully enclosed, compact, and designed for safe use in university or classroom environments. No industrial-scale infrastructure is needed — only standard power and a clean space.

Absolutely. After a short onboarding, students can prepare builds, launch prints, and manage post-processing under supervision. This gives them real ownership of the process and boosts learning through direct experience.

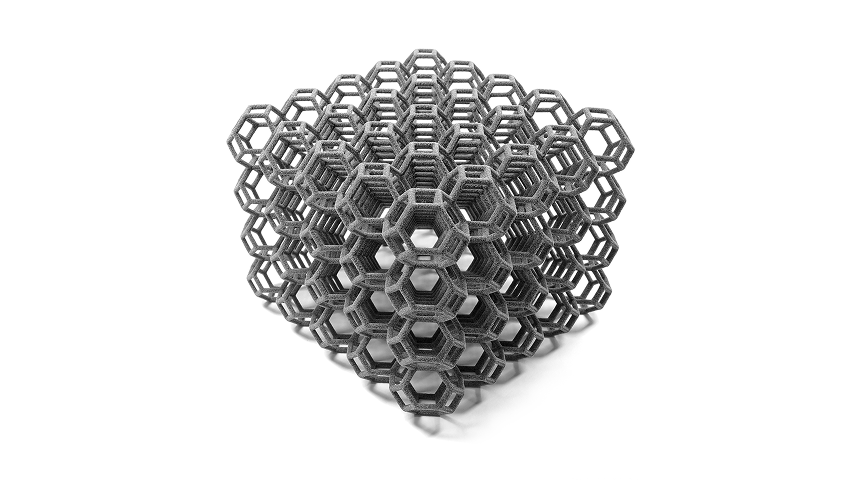

SLS allows students to print geometrically complex, functional parts with no support structures. This better reflects how additive manufacturing is applied in industry — from medtech to aerospace — and teaches real-world problem-solving beyond basic extrusion printing.

Yes, we provide academic institutions with tailored pricing and bundles that often include training, support, and sample materials. Contact us for details specific to your region or curriculum needs.

PA12 Industrial is ideal for structural components and functional projects, while PA12 Smooth offers high surface quality for design and presentation. PA 11.5 is used in mechanical stress tests and is great for student projects involving performance validation.

Definitely. Many institutions use Lisa X or Suzy for a mix of hands-on education and advanced research. With open parameters and repeatable accuracy, it serves both learning and experimentation equally well.

Yes. Sinterit systems require only standard power and minimal space. There’s no need for dedicated ventilation or heavy infrastructure, making it easy to integrate even in shared lab environments.

Yes — and that’s exactly what sets SLS apart. From powder loading and nesting to sintering and cleaning, students get real insight into professional AM workflows used in R&D and production labs.

SLS is used in mechanical and biomedical engineering, product design, robotics, architecture, and materials science programs. It’s a valuable teaching and prototyping tool wherever real part function matters.

Yes. With open printing parameters, educators and researchers can tweak sintering settings, experiment with powders, and conduct controlled studies. This is especially useful for material testing and process optimization.

Yes. They’re ideal for project-based and team-based teaching. Students can prototype, test, and improve their designs iteratively — just like in real product development.

Common use cases include prototyping in design courses, mechanical validation exercises, DfAM workshops, and multidisciplinary capstone projects. Lisa X helps bridge academic theory and hands-on practice.

Of course. Its versatility makes it useful across faculties — one unit can serve engineering, design, material science, and even medical programs. That makes it a great investment for shared labs or tech hubs.

Lisa X prints full build volumes overnight, allowing students to test parts the very next day. This keeps academic projects moving without long lead times or production bottlenecks.

Yes. We offer online onboarding, documentation, and optional on-site training. Educators can quickly learn how to integrate SLS into teaching without technical overhead.