3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

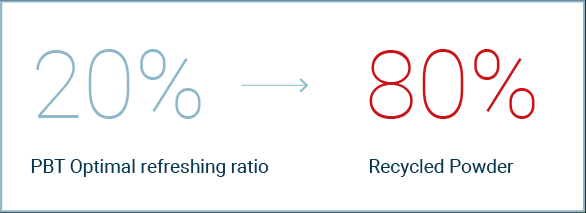

What is the refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.

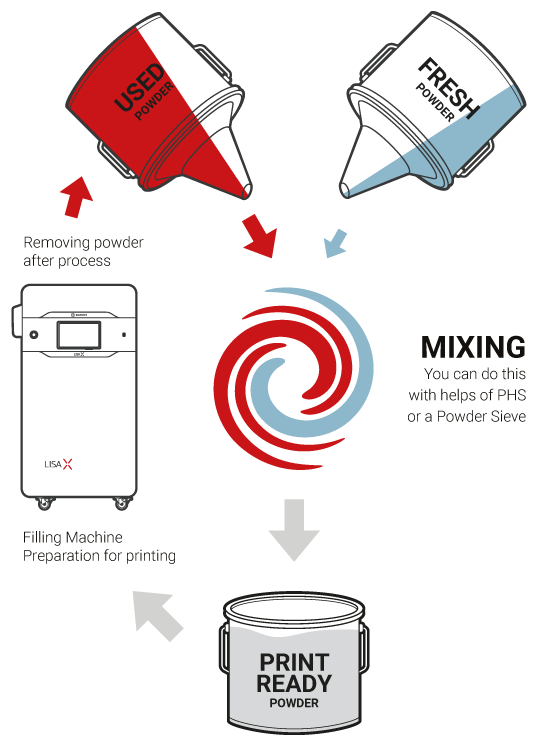

How it works

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material

To start SLS 3D printing you need the powder starter pack. After that, you’ll only need to refresh the powder you own with fresh powder.

PBT Optimal is a Polybutylene Terephthalate (PBT) powder designed for SLS 3D printing with the Lisa X. It offers high rigidity, great detailing, excellent chemical resistance, and very low cost per part, making it ideal for cost-conscious applications.

PBT Optimal is engineered for cost-effective prototyping and production. It features:

– The lowest printing cost per part among Sinterit’s compact SLS materials

– Low refresh ratio (20%), meaning minimal waste and reduced material usage

– Excellent stiffness and fine detail resolution, ideal for precision components

PBT Optimal is specifically optimized for use with the Sinterit Lisa X SLS 3D printer.

No, nitrogen is not required when printing with PBT Optimal.

PBT Optimal is suited for a wide range of technical and industrial applications, including:

– thermoforming molds

– electrical and electronic components

– electronic enclosures

– dental applications

– prototyping and rigid tooling components

– Tensile strength: ~49 MPa

– Tensile modulus: ~2700 MPa

– Flexural strength: ~50 MPa

– Impact resistance (Charpy unnotched): up to 11.12 kJ/m²

– Shore hardness: 77D

These figures indicate high stiffness, moderate impact strength, and excellent dimensional stability

PBT Optimal performs reliably under moderate heat:

– Melting temperature: 172 °C

– Heat deflection temperature (HDT A): 52 °C

– Softening point (Vicat A50): 93.2 °C

These values make it suitable for applications involving moderate thermal stress

Yes — when used as intended with a 20% refresh ratio, PBT Optimal allows for sustainable printing with no powder waste, making it an environmentally and economically responsible choice.

– Color: Dark Charcoal

– Mean particle size (D50): 57 µm

This ensures consistent surface quality and high printing resolution