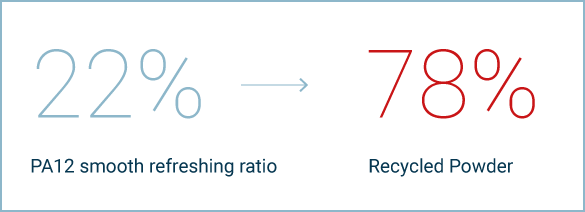

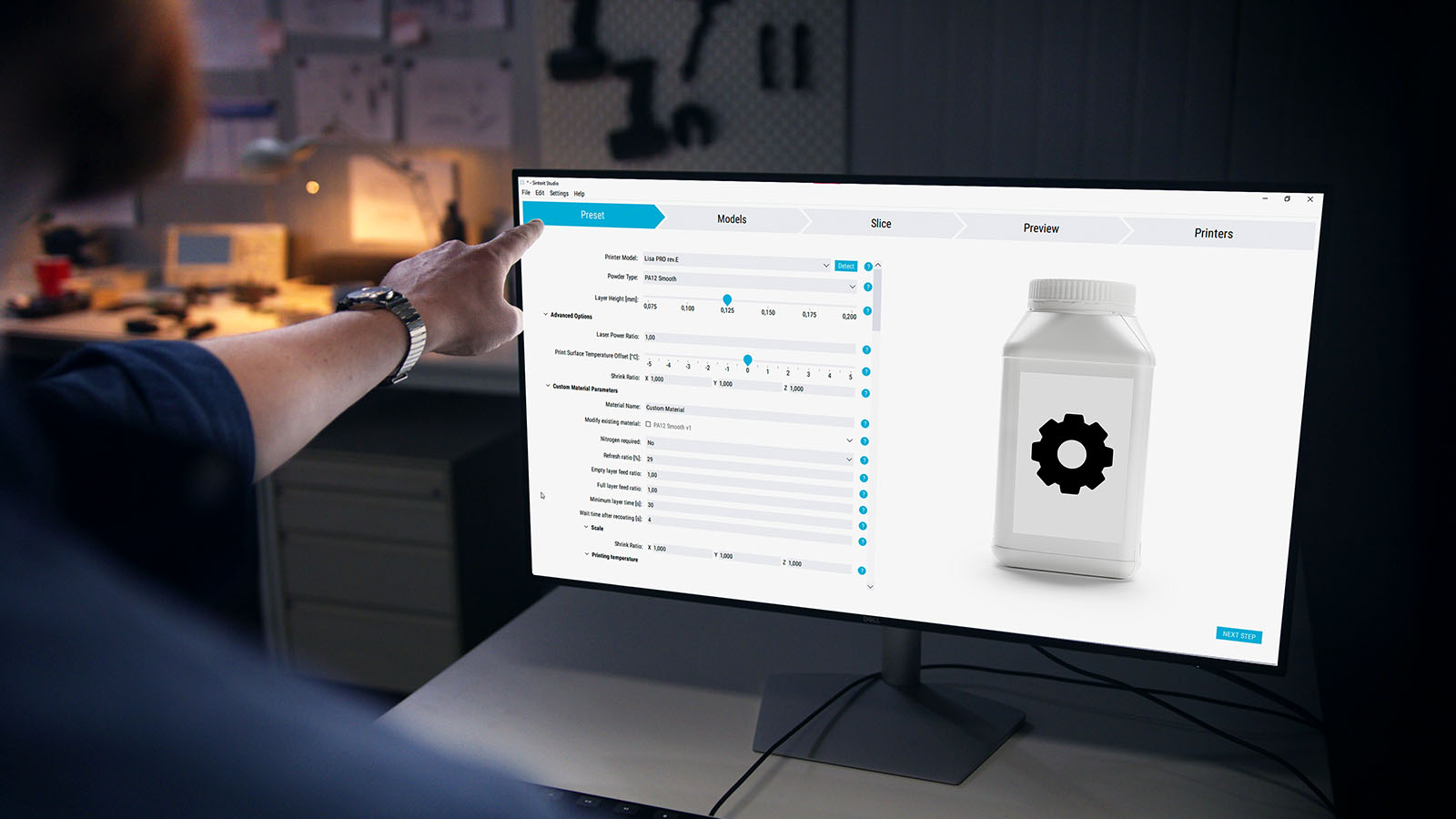

Starter powder is basically a print-ready powder.

In Sinterit we distinguish three powder conditions: print-ready, used, and fresh.

Used is a type of powder that you get after the printing, present in overflow bin or remaining after printout cleaning.

Fresh is a type of powder that is being used for refreshing the powder. After mixing this powder with used powder you will receive print-ready.

Print-ready is a type of powder that you can simply pour into the printer and start printing.

Although printing using Fresh is possible it’s not economically optimal therefore Sinterit printers are optimized for using a refreshed (print-ready) powder.

Austria

Austria  Bosnia and Herzegovina

Bosnia and Herzegovina  Bulgaria

Bulgaria  Croatia

Croatia  Czech Republic

Czech Republic  Denmark

Denmark  Estonia

Estonia  Finland

Finland  France

France  Germany

Germany  Greece

Greece  Hungary

Hungary  Ireland

Ireland  Italy

Italy  Latvia

Latvia  Lithuania

Lithuania  Poland

Poland  Portugal

Portugal  Romania

Romania  Slovakia

Slovakia  Slovenia

Slovenia  Spain

Spain  Sweden

Sweden  Switzerland

Switzerland  United Kingdom

United Kingdom  Ukraine

Ukraine  China

China  Hong Kong

Hong Kong  India

India  Israel

Israel  Japan

Japan  Malaysia

Malaysia  Philippines

Philippines  Saudi Arabia

Saudi Arabia  South Korea

South Korea  Taiwan

Taiwan  Thailand

Thailand  Turkey

Turkey  United Arab Emirates

United Arab Emirates  Egypt

Egypt  South Africa

South Africa  Tunisia

Tunisia  Canada

Canada  Mexico

Mexico  United States

United States  Brasil

Brasil  Colombia

Colombia  Australia

Australia  New Zealand

New Zealand