Learn how your sample may cost.

Send your model to us and our experts will provide a detailed prediction of costs for several scenarios.

ContactPonieważ drukowanie 3D w technologii SLS staje się coraz bardziej popularne, dzielimy się naszymi spostrzeżeniami, wskazówkami i trikami, abyś mógł z nich skorzystać.

Case StudiesDzięki czterocyfrowej skali instalacji drukarek 3D Sinterit na całym świecie tutaj znajdziesz niektóre z opowieści naszych klientów.

Technologia SLSZapoznaj się z podstawową wiedzą na temat selektywnego spiekania laserowego (SLS). Twoja podróż zaczyna się tutaj. Sprawdź, czy jest to odpowiednia technologia dla Twoich potrzeb.

Send your model to us and our experts will provide a detailed prediction of costs for several scenarios.

Contact

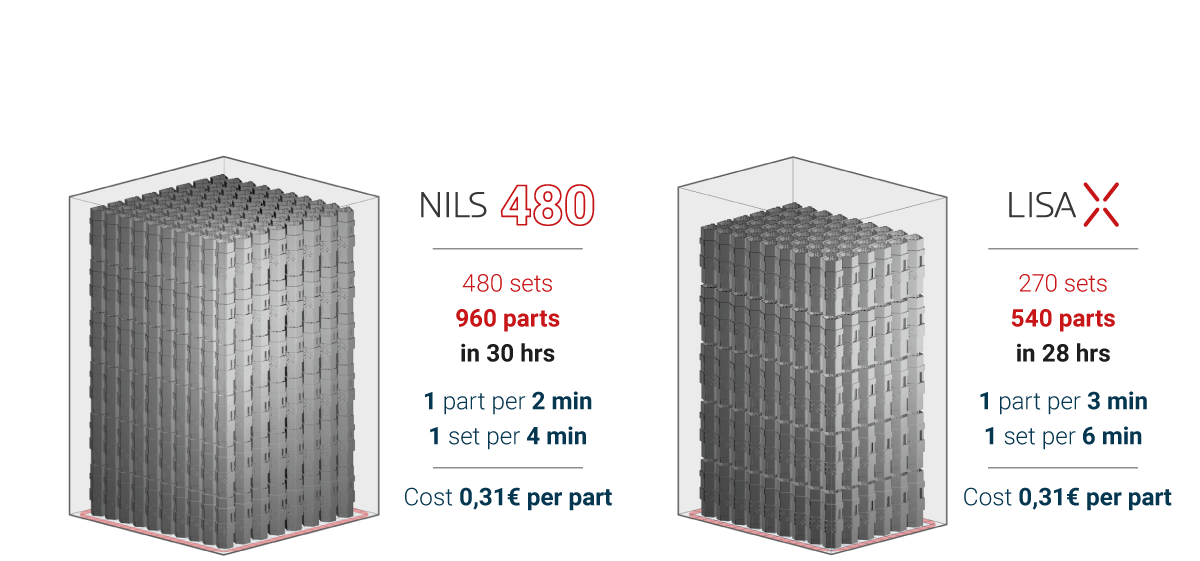

A new industrial SLS 3D printer with the best ROI on the SLS technology market.

Priced individually

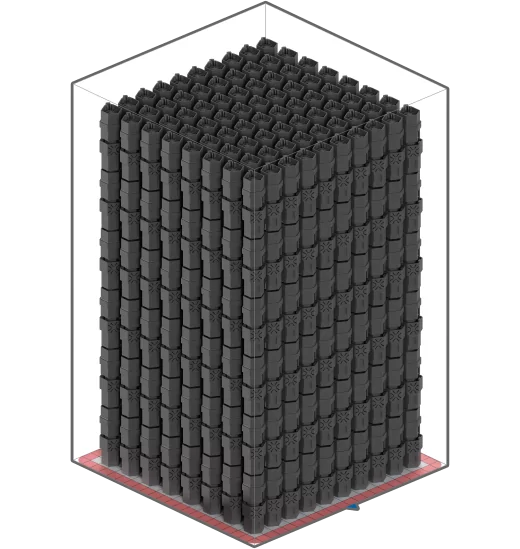

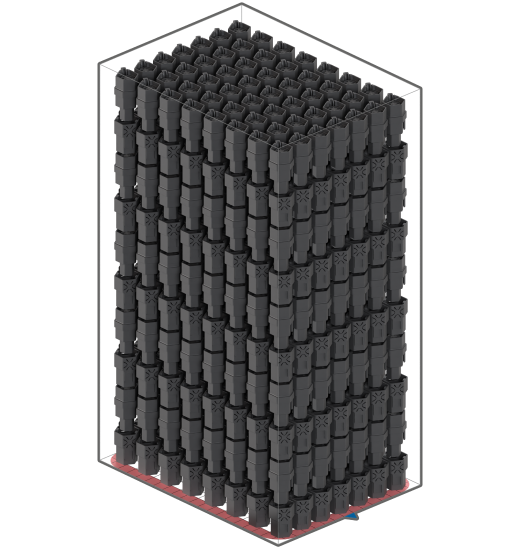

Print batches of top quality SLS parts faster. Larger print volume and revolutionary fast rapid prototyping.

The SLS 3D printer for top-quality functional prototypes, research work, and to speed up the product engineering process.

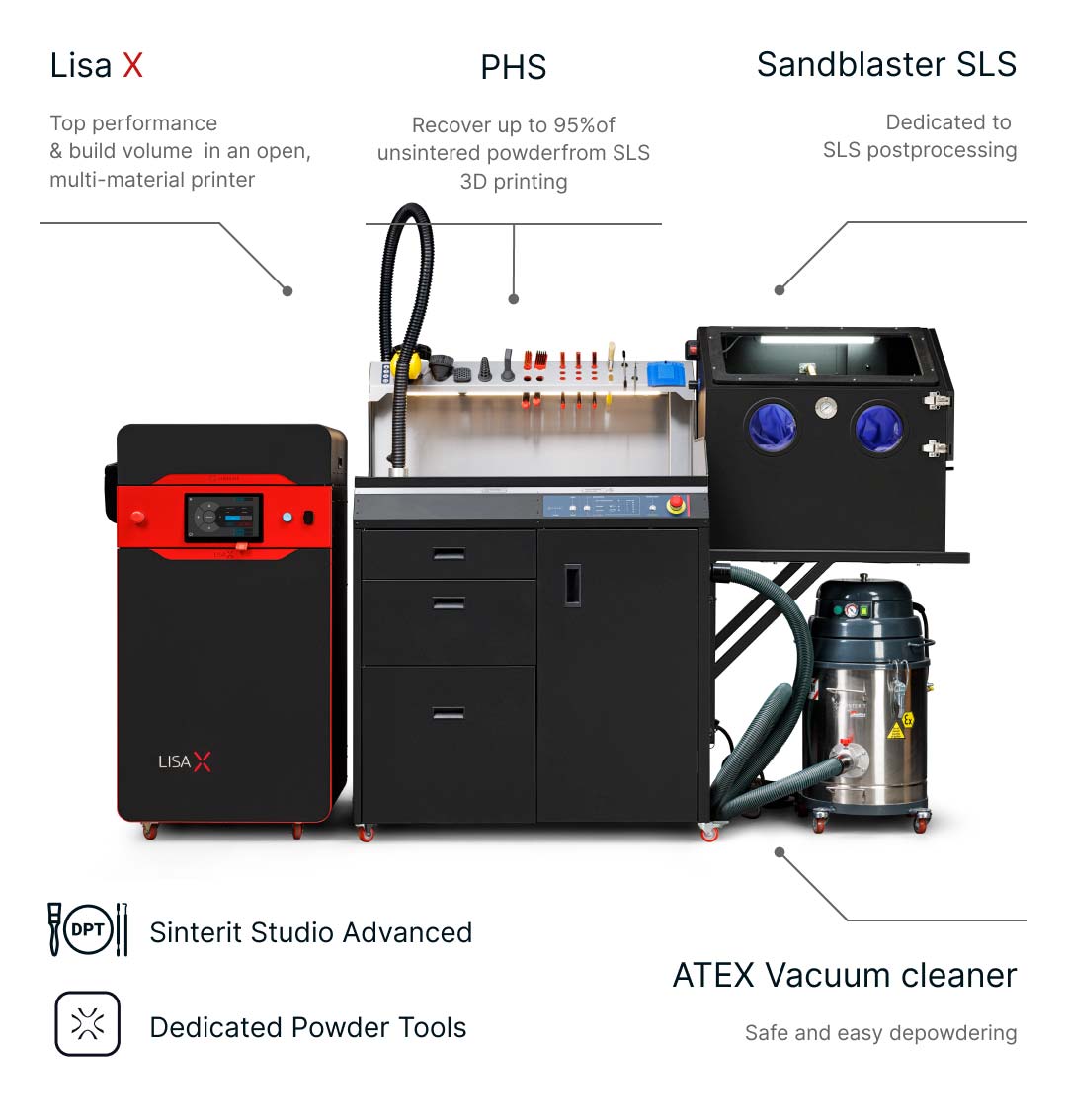

Top performance & build volume in an open, multi-material printer. It offers large build volume and industrial speed & quality

Supporting device designed for dustless work with 3D printouts post-processing and powder recovery

Universal cabinet solution for the surface treatment and depowdering process by glass balls blasting of 3D printed parts

Sinterit Studio Advanced

Sinterit Studio Advanced  Dedicated Powder Tools

Dedicated Powder Tools Universal cabinet solution for the surface treatment and depowdering process by glass balls blasting of 3D printed

Print more, earn faster

Print more, earn faster