3D printing specialized tools for the biotechnology sector with the Lisa PRO

-

Flexible scaling of production parts

-

Print up to 400 parts at a go

-

Simple pre- and -post processing that does not require expert skills

Background

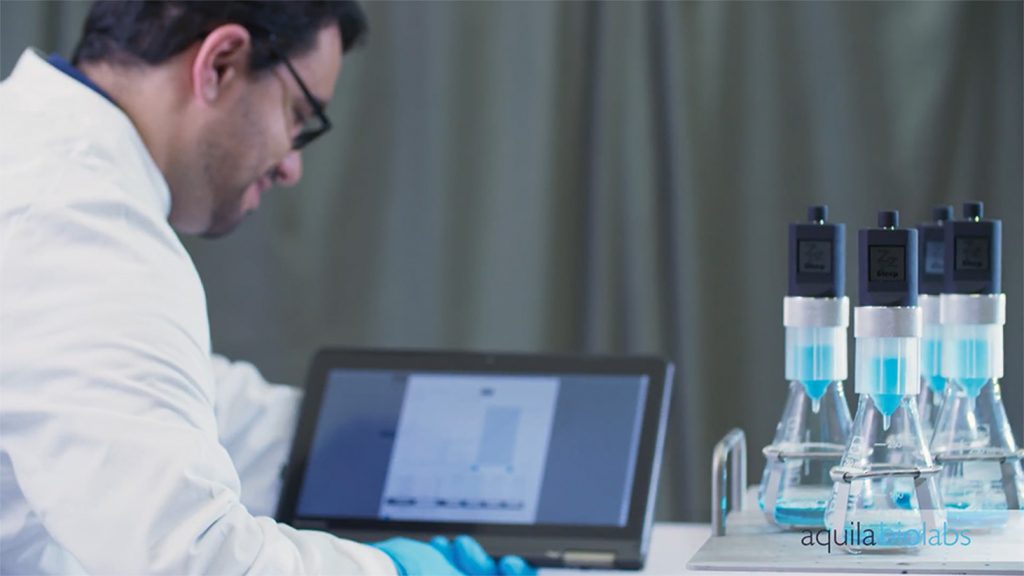

Aquila biolabs GmbH is a German sensor technology developer of smart sensors and state-of-the-art data analytics software for bioprocessing applications. As a subsidiary of the life sciences tool provider, Scientific Industries, Inc., aquila biolabs takes the guesswork out of bioprocessing and pioneers digitally simplified bioprocessing by providing actionable insights from lab to production floor.

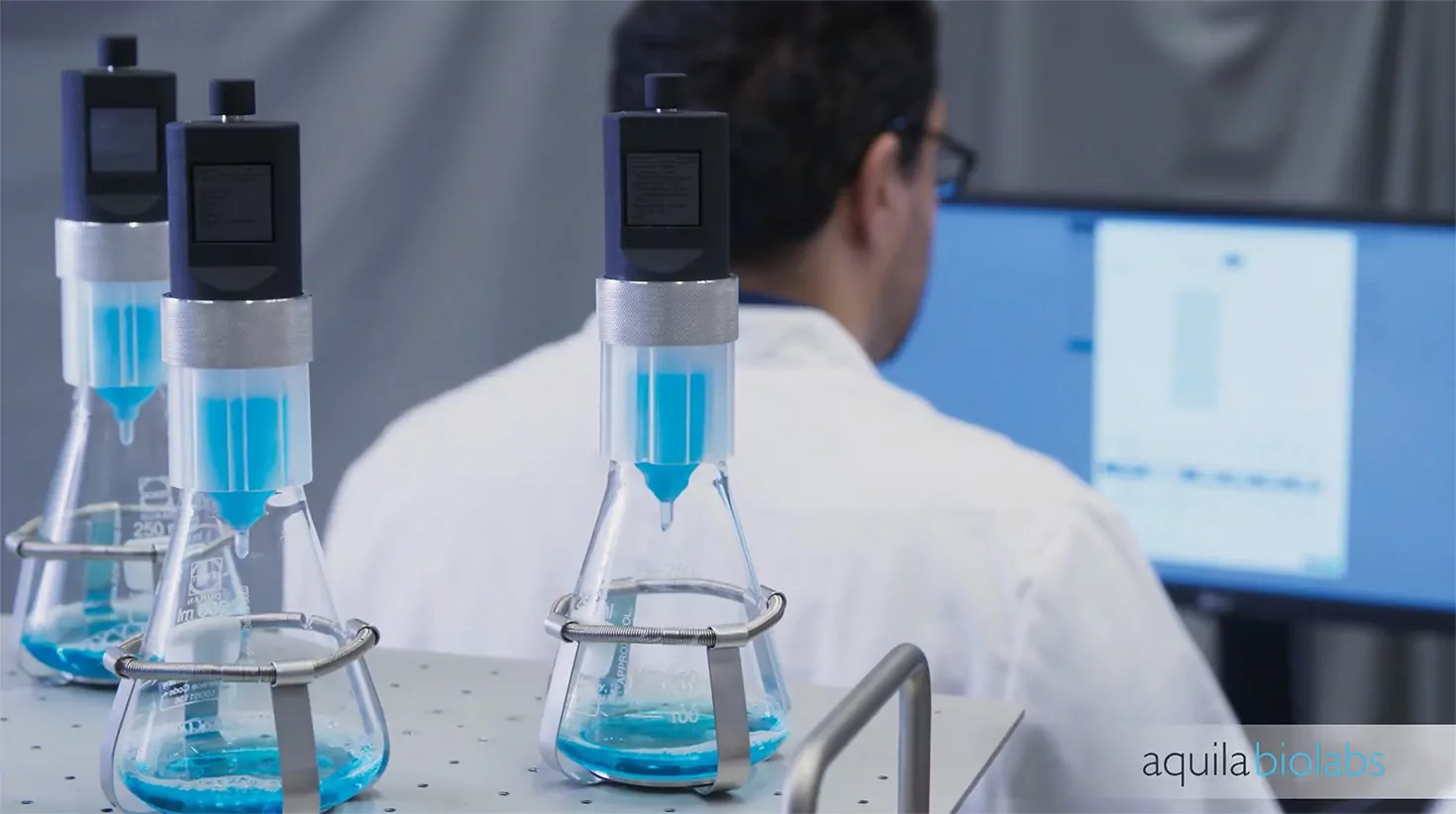

One of aquila biolabs’ products is Cell Growth Quantifier (CGQ), a complete setup of sensors that helps in:

- analyzing biological cultures in shake flasks or bioreactors

- non-invasively plotting the growth of microorganisms inside vessels.

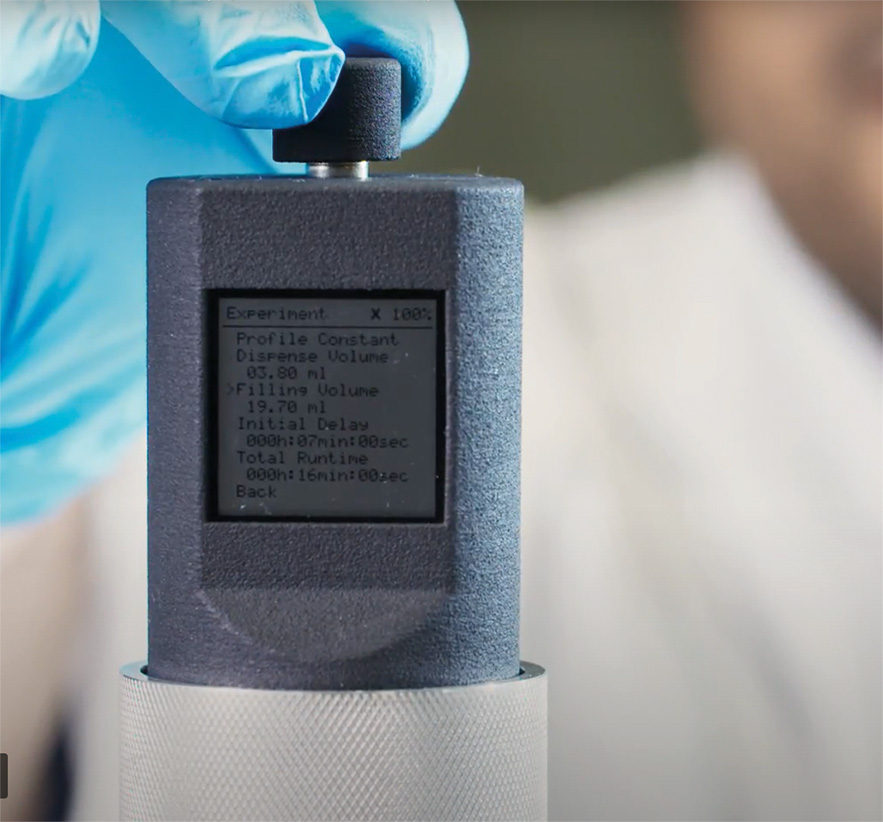

Another of their products is the Liquid Injection system (LIS), an automated miniature pumping system that dispenses fluid directly into a vessel.

Problem

The company’s products are designed to be compatible with a variety of laboratory glassware and equipment. As such, they require flexible production techniques, particularly as customers have wide-ranging expectations of both systems. On a global scale, there are numerous specifications and limitations on shake flasks and bioreactors. In the ever-changing biotechnological world, companies that build sensors for analyzing these vessels, and the cultures within them, need to adapt. 3D printing allows them to produce adapters and parts used in attaching sensors to a wide array of vessel types.

The demand for such elements at relatively low volumes has put aquila biolabs in a tricky position. Custom manufacturing of each configuration would be costly and time-consuming. Also tooling for mass production for so many variants would be too large an investment.

The Covid-19 pandemic is another factor that has driven aquila to rely more on 3D printing. Like many other companies, it has suffered supply chain disruptions. While they have continued to supply work to the biotechnology industry, the future has been murky for many of their own suppliers.

Being acquired by Scientific Industries has helped aquila biolabs ramp up production of the supplies for their products with 3D printing technology, thus becoming more independent. Such production was intended to be flexible enough to meet the changing demand for their products. This was important as it meant they wouldn’t have parts in storage and their Kanban production would be efficient.

All of this led them to search for a 3D printer for their application. Selective Laser Sintering technology seemed to meet their needs in terms of customization for the complex structures their 3D models require.

Learn more

Why the Lisa Pro is ideal for your research

Solution

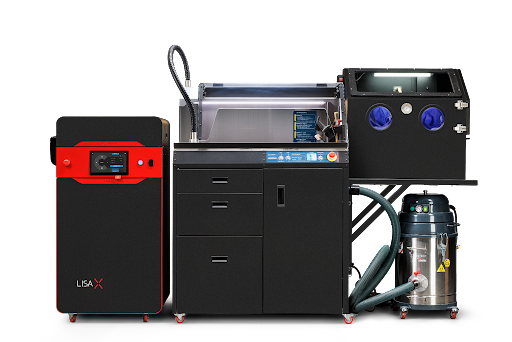

Aquila biolabs appointed its Head of Production, Sayantan Dutta, to lead the charge to produce end-use parts of varying sizes. These would be used to meet the increased demand for adapters and parts for sensors. After thoroughly researching the 3D printer market, Mr. Dutta decided to buy the Lisa PRO for this venture.

The compact size of the printer allowed aquila to meet the changing demand for its parts. If they needed 10 units of variant A and 5 of variant B, Mr. Dutta and his team could plan it and optimize the production accordingly.

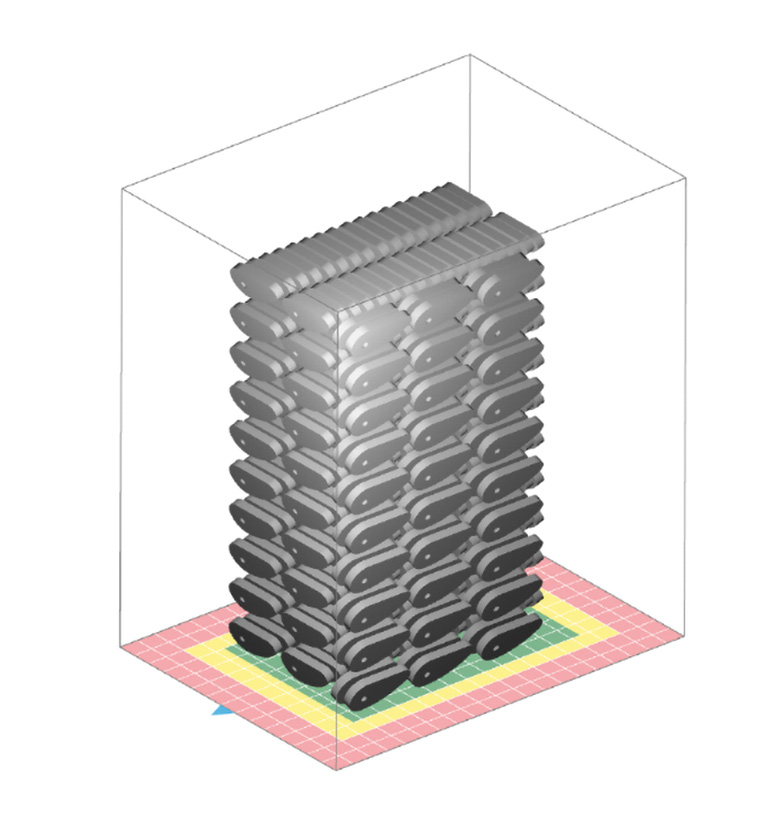

Aquila used the 3D printed elements in its LIS, a complex device containing an internal skeletal structure with electronics and other components and a barrel structure for the outer housing. SLS 3D printing technology could print this structure while the Lisa PRO handled the top details required for the print. As a result, aquila can now produce the devices in-house from start to finish.

Side by side: the metal clamping lever (Left) aquila used to use and that 3D printed PA12 clamping lever (right) they’re using now.

The Lisa PRO also helps the company manufacture small parts with good resolution and quality. For example, it has a clamping lever structure that is a part of an adapter used to hold a sensor plate. The lever was once produced out of aluminum and then anodized and coated black. But Sayantan and his team have found a way to use Sinterit’s SLS technology to print the same part out of PA12. The large quantity of printing possible with the Lisa PRO helps aquila biolabs produce 400 pieces in a single print run. Such improvement radically decreased the man-hours aquila needed for printing and post-processing.

The compact size of the Lisa PRO fits in nicely with their other equipment and is close to the rest of the production stages. While investment in new hardware may be expensive, investing in a newer, larger workshop or modifying a current workspace could be even more financially demanding for them. With the compact Sinterit Solution, aquila biolabs has been able to expand its manufacturing capabilities without having to add special infrastructure.

Aquila has standardized its procedures for producing these parts with Sinterit’s SLS printer. The chemical and mechanical durability of Sinterit’s nylon PA12 has made it aquila’s material of choice.

According to the company’s users, the pre-processing and post-processing of these prints are simple and do not require expert-level skills. It is also important for them that the 3D prints are easy to clean with the Sinterit Sieve and powder handling tools, which together speed up the post-processing.

For producing metal clamping levers, aquila Biolabs follows even further post-processing steps. The parts are sieved from the PA12 material and then placed in a large flask with water and sand. The flask is then placed on top of an orbital shaker and agitated overnight. The small structures strike each other while agitating, displacing and dislodging the leftover powder on the surface of the structure and releasing it into the water. Following the overnight agitation cycle, cleaning up the prints is as simple as rinsing them off – they don’t need to be individually brushed or cleaned.

What is also interesting, after the successful implementation of the project, more people are being involved in SLS 3D printing at aquila. For example, Ms Kiersten Bradnam, Hardware engineer is trained to start prototyping and manufacturing of small structures so the company may use the Lisa PRO on a larger scale.

„The Sinterit system is a comprehensive system covering both the printer to all needed parts related to the printing and postprocessing. With this solution, we saved hours of work, and have gained the ability to be independent of external suppliers.” – Sayantan Dutta Head of Production, aquila biolabs GmbH

Visit our customer’s website:

-

Flexible scaling of production parts

-

Print up to 400 parts at a go

-

Simple pre- and -post processing that does not require expert skills