3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

What is the refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.rn

How does it work?

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material

With proper storage and refreshment of 20% with each cycle, there is no need to replace the base, unless there are print imperfections or a reduction in the mechanical parameters of the prints.

No, you should not mix the materials.

According to the manual, carry out the cleaning and sealing replacement cycle of both the printer and the cleaning station.

Flexa Performance is a high-strength, flexible TPU powder designed for Selective Laser Sintering (SLS). It’s ideal for parts that require both flexibility and durability, such as gaskets, joint covers, and vibration dampers.

Flexa Performance is specifically optimized for the Sinterit Lisa X printer, ensuring the best results in terms of part quality, speed, and mechanical performance.

– Tensile strength: ~8 MPa

– Elongation at break: 173–183%

– Shore hardness: 88A

These values provide a strong balance between flexibility and toughness — suitable for both static and dynamic parts

No, nitrogen is not required to print with Flexa Performance on Lisa X.

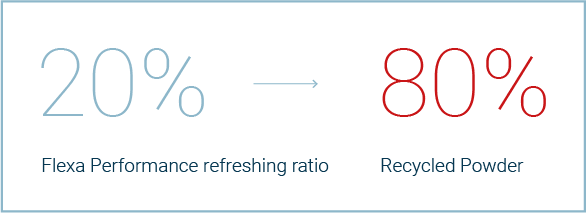

The recommended refresh ratio is 20%, meaning you should add 20% fresh powder to the unsintered material after each print. While the powder is technically 100% reusable, adding fresh powder helps maintain optimal print quality.

– Shoe soles and insoles

– Flexible protective covers

– Functional grippers

– Production tools and fixtures

– Vibration isolation components

All of these benefit from the material’s excellent tear resistance and resilience to repeated bending.

– Density: 1.05–1.11 g/cm³

– Water absorption: 0.87–1.66%

These values indicate a dense, durable structure with moderate moisture sensitivity — suitable for most indoor industrial uses.

– Melting point: 120–150 °C

– Softening point (Vicat A50): 96 °C

These parameters support moderate heat resistance, making Flexa Performance suitable for warm environments but not high-temperature applications.

– Color: Light grey

– Mean particle size: 70–90 µm

This ensures a clean surface finish and high-quality sintering performance.