3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

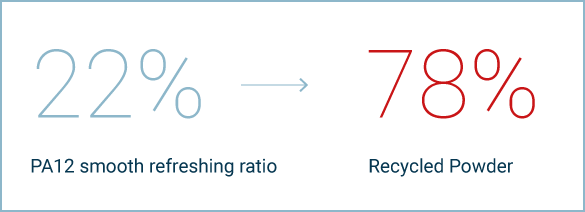

What is the refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.

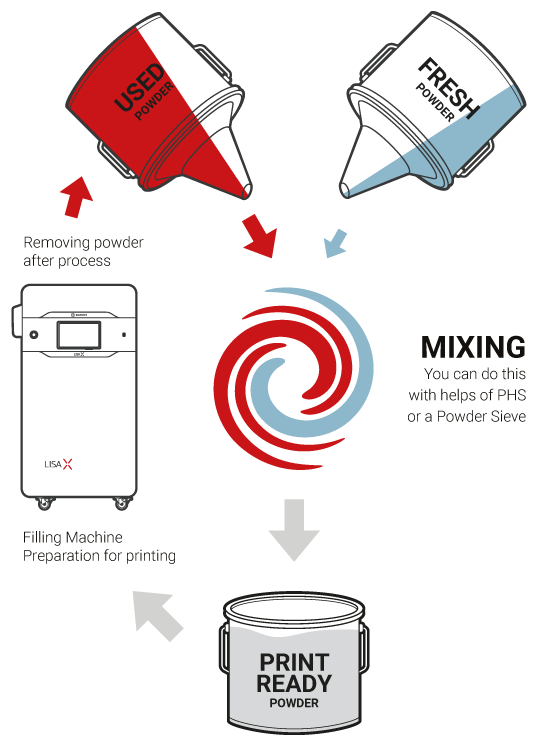

How it works

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material

To start SLS 3D printing you need the powder starter pack. After that, you’ll only need to refresh the powder you own with fresh powder.

– Store the powder at room conditions ( ~23°C and 50% humidity – the lower humidity the better)

– Always store the material in a sealed dry box/container.

– Do not leave the container open.

– Clean the machine directly after printing and store the material immediately after removing the print cake.

– Do not let the powder stay in the printer for more than a couple hours.

– Put a few silicone absorbers in the container (but don’t add them to the printer)

Contact Sinterit support with your questions.

Starter powder is basically a print-ready powder.

In Sinterit we distinguish three powder conditions: print-ready, used, and fresh.

Used is a type of powder that you get after the printing, present in overflow bin or remaining after printout cleaning.

Fresh is a type of powder that is being used for refreshing the powder. After mixing this powder with used powder you will receive print-ready.

Print-ready is a type of powder that you can simply pour into the printer and start printing.

Although printing using Fresh is possible it’s not economically optimal therefore Sinterit printers are optimized for using a refreshed (print-ready) powder.

SLS polyamide powder used for 3D printing is considered particulate matter because of its size. Polyamide powder particles are generally 40 micrometers or smaller. If vacuumed in an ordinary vacuum cleaner, the powder could cause an explosion.

Such materials are subject to labor regulations on air quality and occupational safety. The procedures call for appropriate maintenance of powder at work. Only certified industrial vacuum cleaners should be used to clean such materials. More information about the ATEX Vacuum cleaner can be found here.

Contact Sinterit support with your questions.

PA12 Smooth is a cost-effective Nylon 12 powder offering excellent surface resolution, good chemical resistance, and a great quality-to-price ratio. It’s ideal for detailed prints and general prototyping.

Yes, it has been tested under ISO 10993 standards and found to be non-cytotoxic and non-irritant—but final use applications must be validated by the manufacturer.

It is compatible with the Sinterit Lisa X, as well as older printer generations: Lisa and Lisa Pro.

No, nitrogen is not required when printing with PA12 Smooth.

PA12 Smooth works well for structural or mechanical elements, complex shapes, final parts, and chemically resistant prototypes.

The refresh ratio is 22%, meaning 22% fresh powder should be mixed with 78% unsintered material from the previous print.

It offers high chemical resistance, suitable for parts exposed to various chemicals. For detailed resistance data, contact Sinterit.

PA12 Smooth is specifically formulated to deliver excellent surface quality and fine detail reproduction, even on complex geometries.