3D Printers

SLS 3D Printers

Peripherals

Printers ecosystem

Customer Zone

Start by removing the cake with the IO box so it can be smoothly moved from the printer area and put on the Multi PHS to depowder the prints. After removing the unsintered powder from the print, turn on the Multi PHS to begin collecting the powder. The sifting and refreshing process take place in the Multi PHS. You only need to fill in the powder chamber with the refresh powder; Multi PHS will mix it for you. After refreshing, move the container with refreshed powder out to reuse it for the next print.

Contact with the powder was limited at each stage of the process.

The IO Box (added to the printer) helps move the print cake out carefully and slowly, limiting the powder mess. Once you have a print cake on the Multi PHS space cleaning the print, the unsintered powder goes down so you don’t have to move the powder to another place.

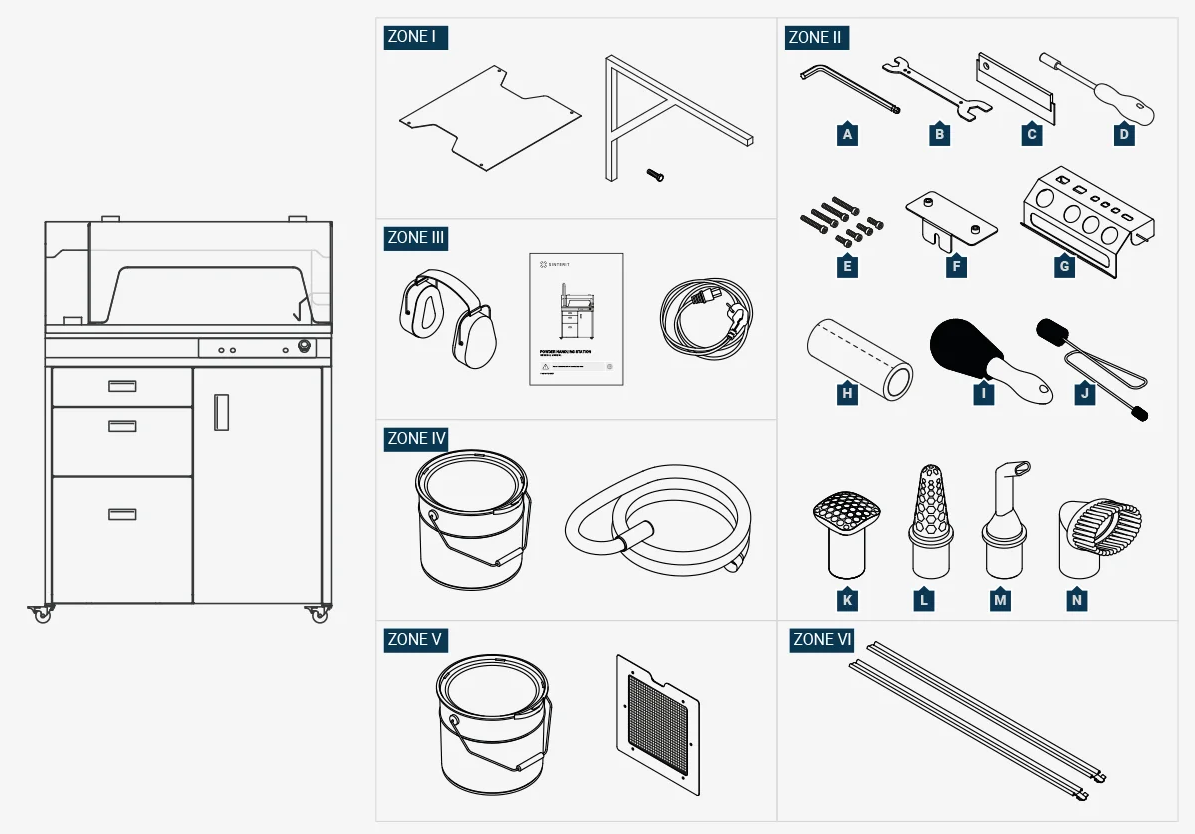

The suction hose and powder wiper (attached to the Multi PHS) help you clean up after the depowering stage.

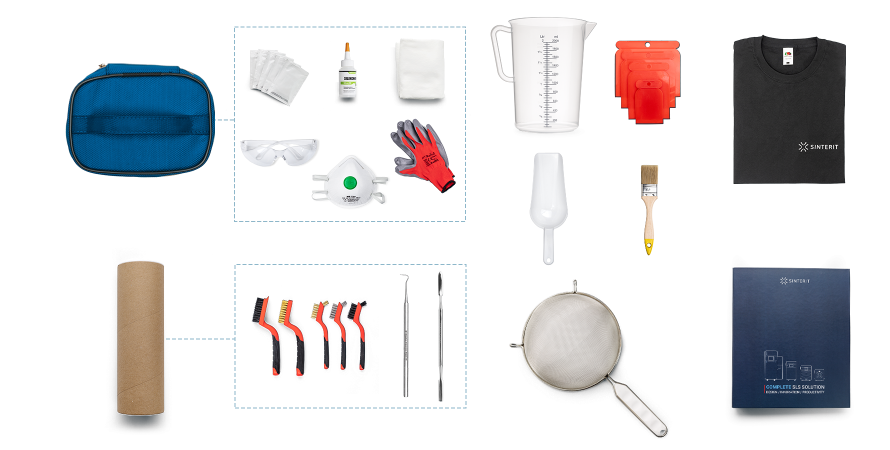

To limit the spread of powder, use the funnel when adding fresh powder from the container to sifted, unsintered material. The funnel is available in our Dedicated Powder Tools set.

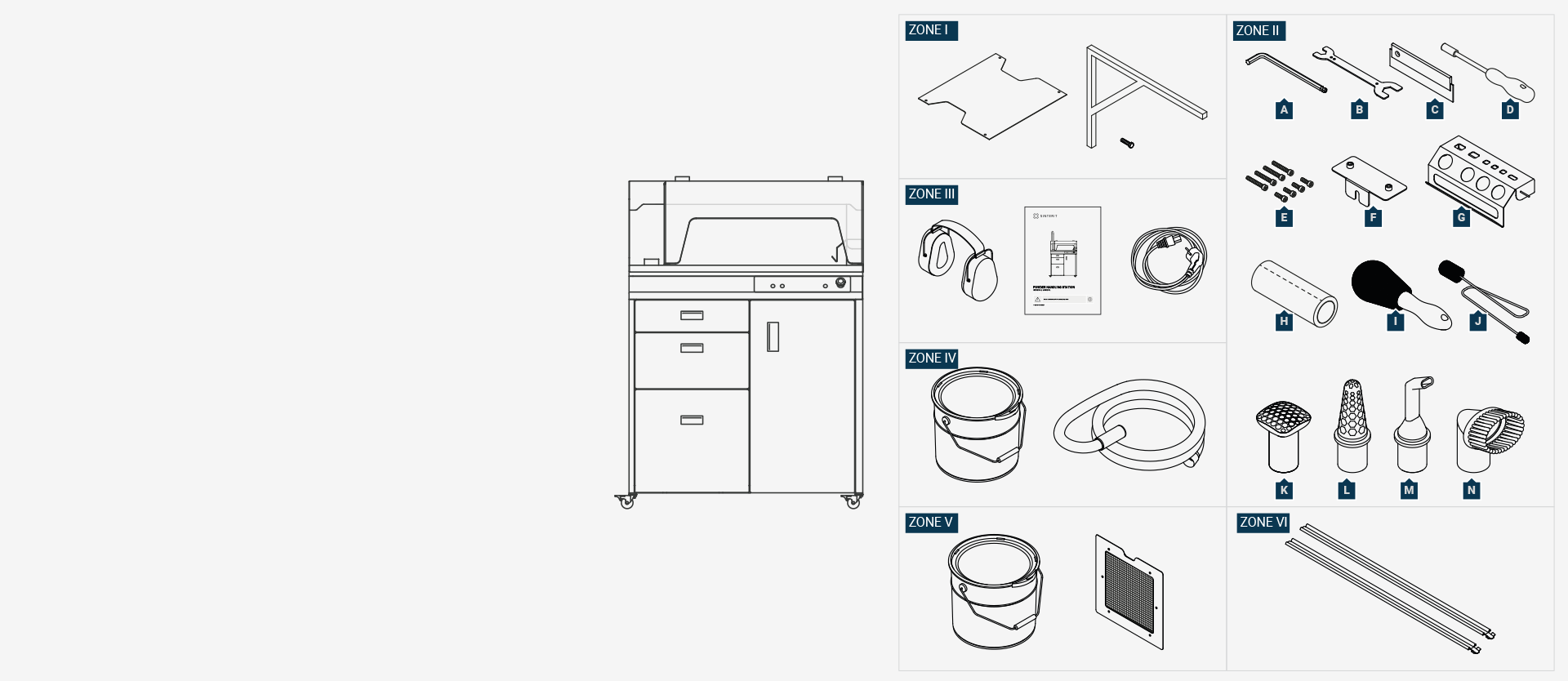

There are several new features added to Multi PHS:

– Plexiglass cover to minimize the spread of dust.

– Movable tool holder.

– Adjustable workspace compatible with printouts from LisaX and 3rd party SLS printers.

– 5 sifting programs for morphologically different materials.

– Ability to separate the sieve for solo-sifting.

– Overall improvements in UX/UI and workstation construction.

You can unplug the sieve from the Multi PHS, slide it outside on the guides and use as a separate sifting unit. It’s a useful feature if you print from rarely used material, and don’t want to clean the whole workstation just for it. You can clean the printout separately (eg. on folding tray) and then sieve the remaining powder for further use.

No, you can post-process printouts without the workstation. Your decision to purchase depends primarily on your specific printing requirements.If you plan on printing a large number of parts or using multiple types of SLS powders during the printer’s lifetime, it’s advisable to consider purchasing the Multi PHS. It saves your time, effort, material, and consequently, money.

Up to 98%, on average it can be closer to 95%.

Cleaning time can range from 10 to 30 minutes, depending on the used material.

Yes, the use of Multi PHS is completely safe. The main risk factors like vapors, airborne dust, ignition, and explosion are thoroughly tested to ensure they are contained within safety guidelines. In addition, Multi PHS is ATEX attested as a part of the Performance set.