How much can you print from 1kg?

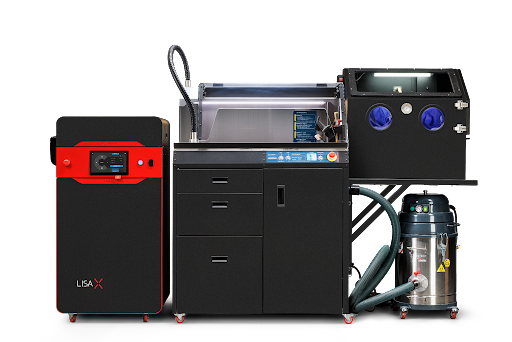

Let’s find out. First of all it may be a little bit tricky to operate in kilograms as the main unit we operate in SLS 3D printing is one liter. Let us therefore assume, in accordance with the facts, that 1 kg of PA12 powder corresponds to 2,2 liters of PA12 Smooth, and about 1,99 liters of PA12 Industrial available with Lisa X. With the last one we can begin.

Smaller base surface, the higher model

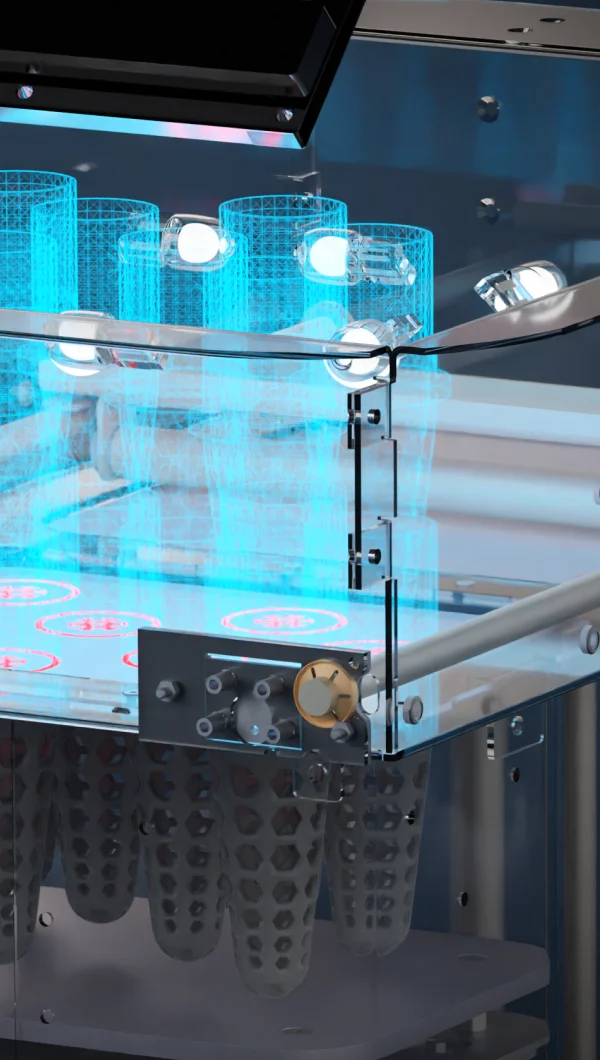

Our calculations are based on Lisa X which is Sinterit’s flagship compact SLS 3D printer. The print volume in Lisa X has 130 x 180 x 330 mm. But it is not the size of a printing chamber, which is slightly wider – 150 x 200 mm. The first important acknowledgement is that with a larger base surface of the printing chamber you will get a lower printout assuming the same volume of the powder.

It is important to remember that in SLS 3D printing technology the model orientation is the king. Some models need to be printed almost vertically to maintain the best quality. It can mean using more powder, as you need to accommodate the required height.

8 gears for 1 kg

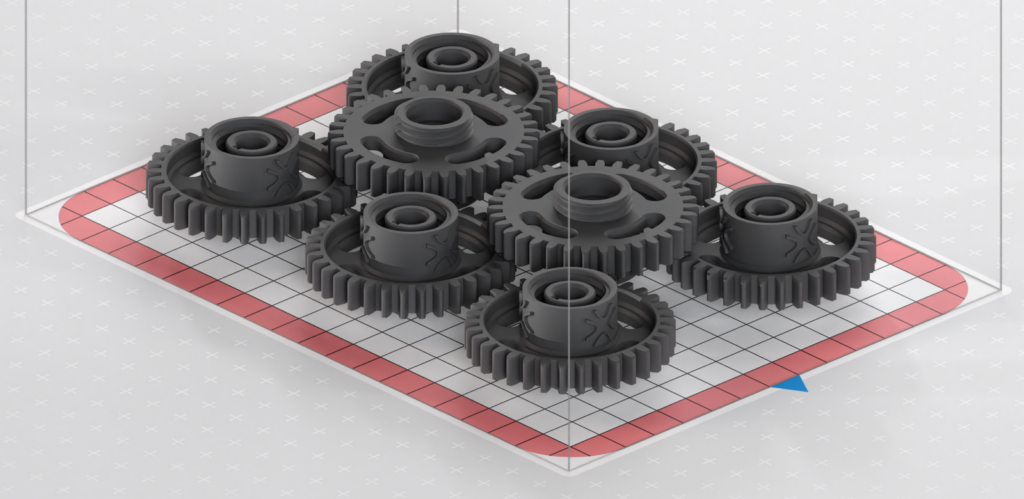

To present how much you can print with 1 kg (2 l) on Lisa X we choose a relatively low model that can be printed flat. Why is this orientation good? First of all, it guarantees the sharpness of the gears itself. Secondly, with holes and perforations, the heat can escape upwards, preventing the printout from bending and warping. The archetype of this model is a cylinder which is also not prone to banding, and as the model is quite small, it also influences great quality of the printout.

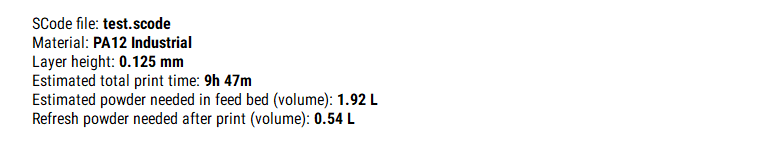

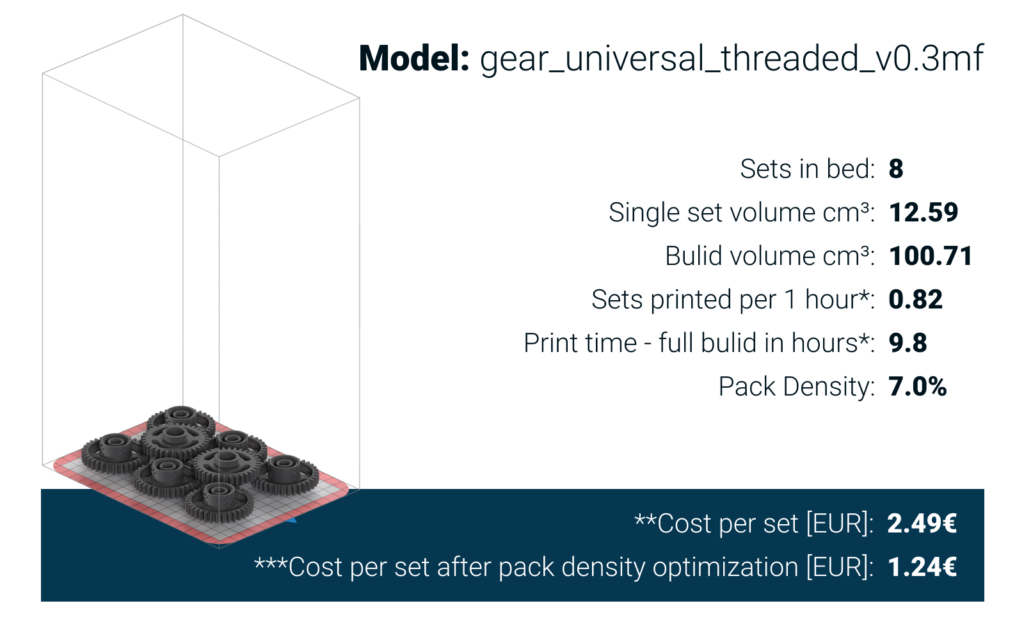

In this scenario we fitted eight parts. After slicing, with the layer height of 0,125 mm, we know that the estimated amount of needed powder is about 1,92 l so slightly less than 1 kg. We also learn, that after printing ends, that we will need to refresh the unsintered powder with about 0,54 l of a new, fresh one.

How much does it cost to print those parts?

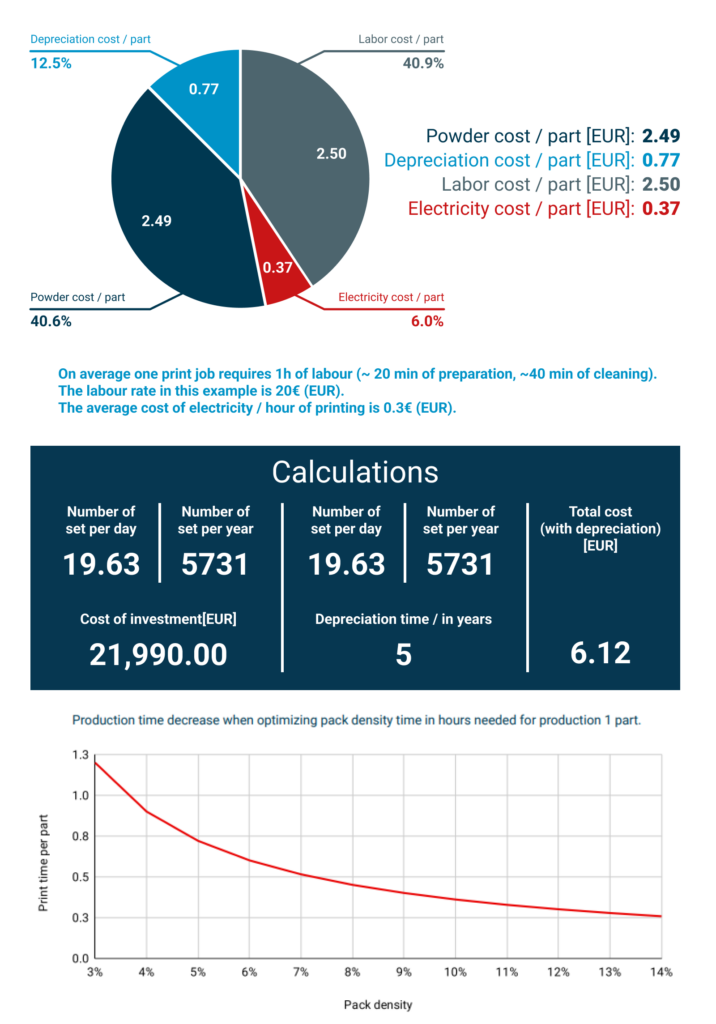

The cost per part depends on many factors, but one of the most important is pack density. The chart below shows the relationship between the price and the degree of packing in the bed. As you can see, the more dense the arrangement, the lower the price. Our set has 7% pack density which results in a price of 2,49 EUR per part.

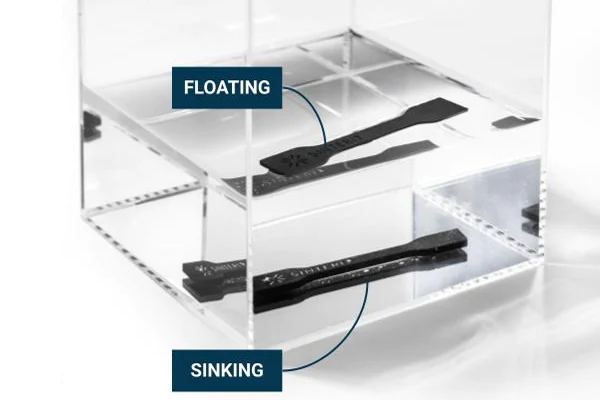

How much powder is left after the printing ends?

Assuming that two liters of powder has 2000 cm3 and the printed parts have all together 100 cm3 we still have about 1,8 l of unsintered powder to use. Why 1,8 l instead of 1,9 l? The SLS 3D printing process makes the sintered powder double its density. So we need to assume that 100 cm3 will finally reach about 200 cm3.

How much of it can we regain? If we use dedicated post-processing tools – most of it will be ready for the next prints.

Conclusion

Compact SLS 3D printers are very cost effective in terms of printing small batches. You don’t have to invest much in the materials to start printing. As you can see below, the labor costs are in this example equal to the powder costs. But our job was to estimate the number of printouts we can achieve from 1 kg of powder. To optimize labor costs you need to print more models at once. Greater density will also make the final part cheaper.