FDM vs SLA vs SLS: which 3D printing technology is right for you?

When choosing a 3D printing technology, it’s crucial to understand the strengths and trade-offs of each method. This comparison of FDM vs SLA vs SLS highlights key differences in materials, surface finish, cost, speed, and design freedom. Whether you’re deciding between stereolithography vs FDM or evaluating SLS vs SLA for functional prototypes, this guide provides a clear overview to help you choose the right solution for your application.

FDM (Fused Deposition Modeling): affordable 3D printing for prototypes

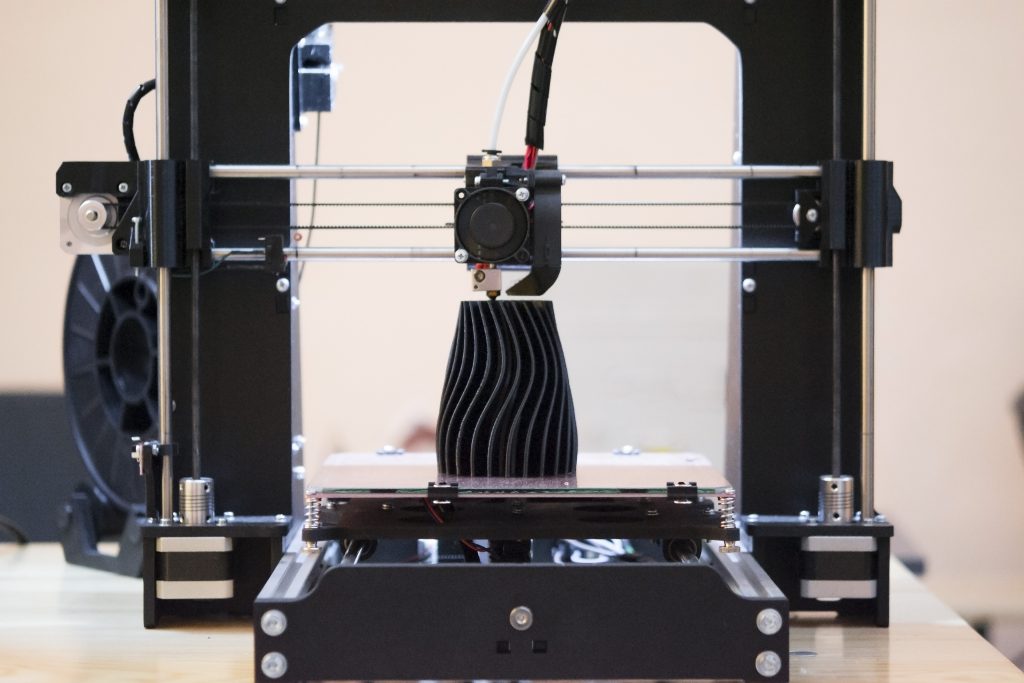

Fused Deposition Modeling (FDM), also known as FFF (Fused Filament Fabrication), is the best-known technology, and a part of the Material Extrusion process. It uses thermoplastic materials, typically in the form of spools of filaments. The heated nozzle of the extruder melts the material which is then deposited onto a substrate. There are several advantages of FDM. The printing process is easy to learn, medium-fast and usually doesn’t require a lot of space. The majority of printers are desktop-sized which makes them ideal for the office. But on the other hand, FDMs are also used as big industrial machines, to support manufacturing processes. In such cases, pellet form of the build material can be used rather than a filament.

Businesses and individual users use FDM for creating functional prototypes, product concept models or rapid tooling. Medical models are getting to be popular as some of the producers got the FDA approval.

Designing for FDM

To create models for FDM 3D printers you need to use a computer-aided design (CAD) or a 3D computer graphics software. This technology has some troubles with hollow parts, undercuts and overhangings, so support structures like boxes, ceilings or webs must be designed and fabricated, in order for the models to be printed.

Fortunately, software analyzes the models and based on their geometry designs appropriate support structures for us. FDM 3D printers with only one extruder create supports from the same material as the whole model is made. In this case, they must be mechanically detached.

Devices with dual or even more extruders are becoming more and more popular nowadays. It makes it possible to use supporting material that dissolves in water, but the process is rather long, sometimes it is more than water you need to use, like a citric acid.

Finally not every printing material sticks to the dissolving support material. The other important factor is the model orientation on the building platform. It must be arranged in a way that it doesn’t require a vast amount of supports.

Advantages of FDM

- Non-toxic, but some filaments like ABS produce toxic fumes. Usually it is environmentally safe process.

- Wide range of colorful printing materials, not so expensive, and with high utilisation.

- Low or moderate costs of equipment.

- Low or moderate post-processing costs (support removal and surface finishing).

- Best for medium-sized elements.

- The porosity of the components is virtually zero.

- High structural stability, chemical, water and temperature resistance properties of materials.

- Rather big build volume comparing to other desktop technologies: 600 x 600 x 500 mm.

Disadvantages of FDM

- Limited design options. Can’t produce thin walls, acute angles, sharp edges in vertical plane.

- Printed models are the weakest in vertical build direction because of the anisotropy in material properties due to additive layer method.

- Supports are needed.

- Not very accurate, with the tolerance between 0.10 to 0.25 mm.

- Tensile strength is approximately two-thirds of the same material that has been injection-moulded.

- Difficult to control build chamber temperature, which is crucial for best results.

- Problem of “stair-stepping” in vertical build plane.

SLA (Stereolithography): high-resolution 3D printing with resin

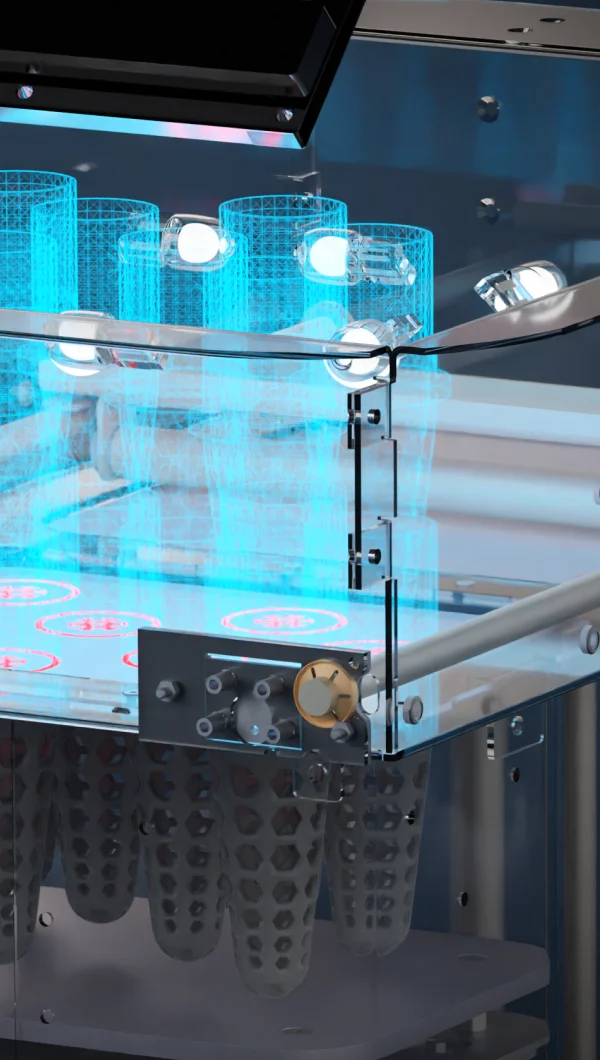

The second most popular process called SLA (stereolithography) is a part of vat photopolymerization. This is the first AM technology that was patented. In this process, a vat of photopolymer resin is exposed to a laser beam or digital light projector. The energy source hardens the material layer-by-layer on the platform.

When it is done, the platform moves up and a layer of resin floods the surface. It is important, that the vat is enclosed to prevent the escape of resin fumes. The chamber itself needs to be opaque or tinted to prevent ambient light from curing the process prematurely.

In SLA, same as in FDM, support structures are needed. But in this case they are always made from the same material. When the printing is done, the completed part is drained, washed in solvent which removes excess resin and afterwards subjected to UV light to cure the component completely. Only then support structures can be removed by cutting.

With SLA you can print from a range of photopolymers like epoxy, urethane, acrylate, elastomer and vinyl. You can use those materials to produce non-functional prototypes, snap fits and hinges, medical models, especially for dental uses, as well as casting patterns.

SLS (Selective Laser Sintering): support-free industrial-grade printing

When designing models for SLA you need to obey the nearly same rules like designing for FDM. Because of the needed structures, the part should be arranged in a matter that will eliminate the redundant supports, which in SLA can take the form of webs, points, ceilings or gussets. Finished parts are translucent, and the layer thickness can be as low as 0.05 – 0.15 mm.

Advantages of SLA

- Excellent surface finish with layer thickness between 0.05 – 0.15 mm.

- Finished parts can be painted.

- Moderately fast.

- Economical for low production (1-20) parts.

Disadvantages of SLA

- Expensive materials.

- Post-processing is not only required but also multithreaded, messy process. After the print is done, the resin needs to be washed in an ultrasonic bath or by dunking a part in IPA (isopropyl alcohol), then the supports must be removed and after that, the printouts needed to be cured with UV light.

- The resin alone is toxic, but mixed with IPA is even more dangerous. The liquid should be secured and sent for disposal to a specialized company.

- Waste material is not recyclable and is hard to manage

- Supports are needed

- Printouts are the weakest in vertical build direction due to anisotropy in material properties because of the additive layer method.

- Laser needs to be calibrated periodically

- The layer-thickness may vary in different resins

- Photopolymers are toxic, as well as the fumes that are escaping during the process.

SLS – Selective Laser Sintering

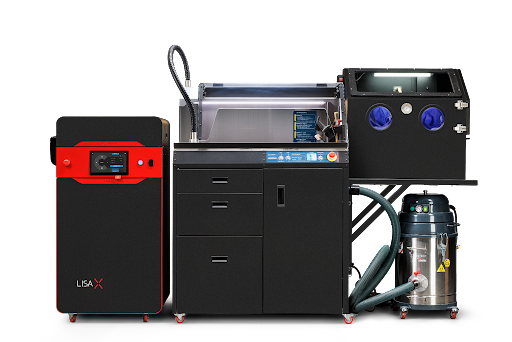

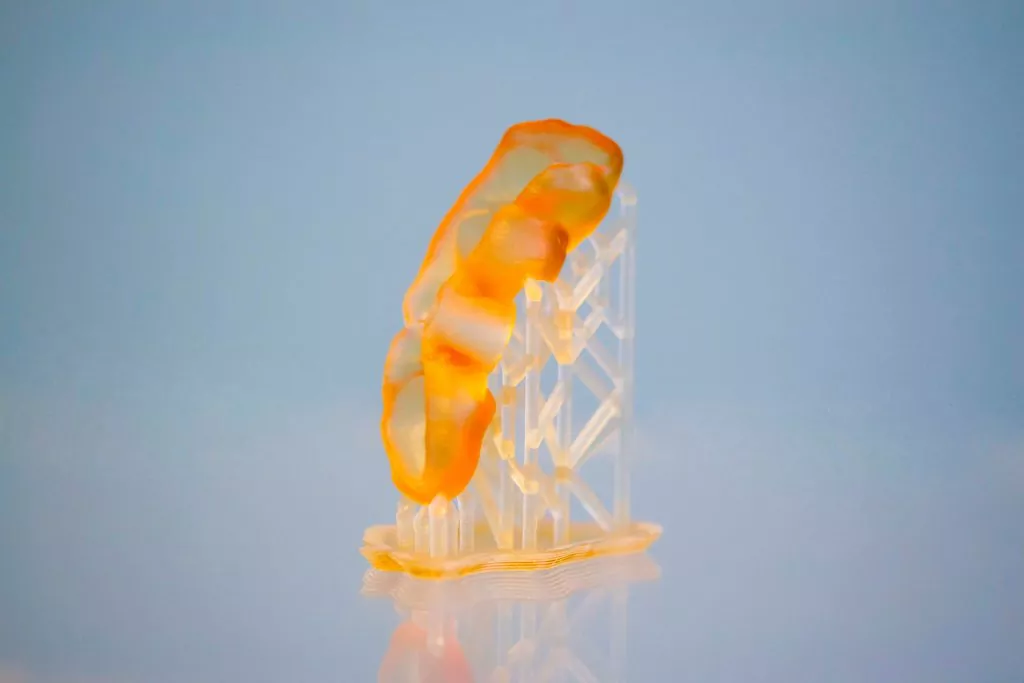

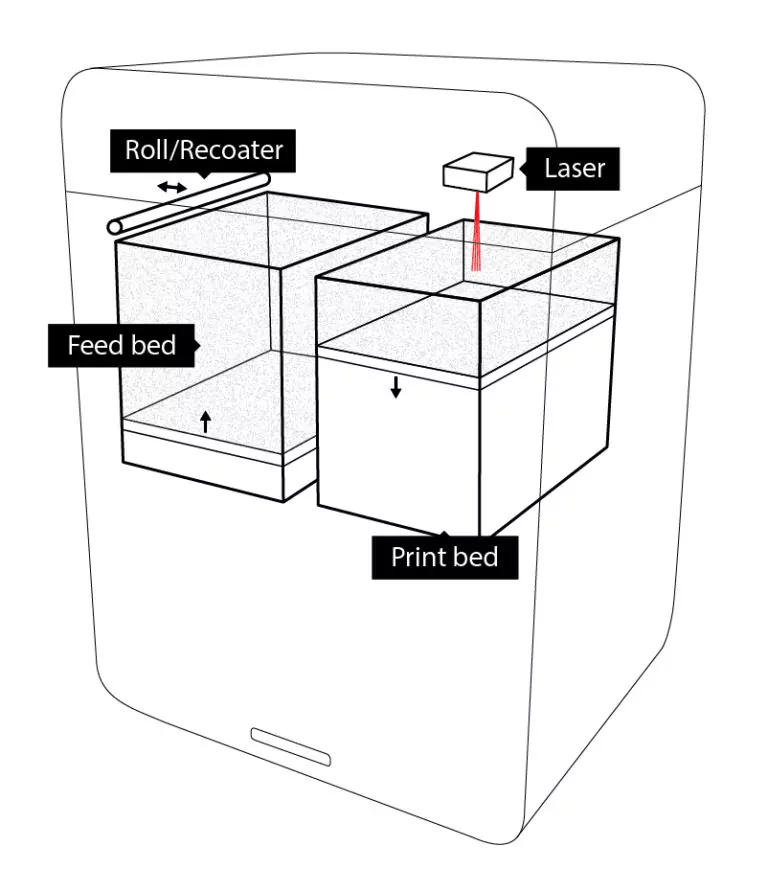

SLS has one of the longest history in 3D printing industry, is best known and as for today, the most predictable additive manufacturing technology. The way it works is very simple. A laser beam sinters powdered material in a sealed chamber, sometimes with an inert gas atmosphere to prevent oxidation. As the chamber is preheated, just below the melting temperature of the powder, the laser is only used to add a little amount of energy to melt the powder.

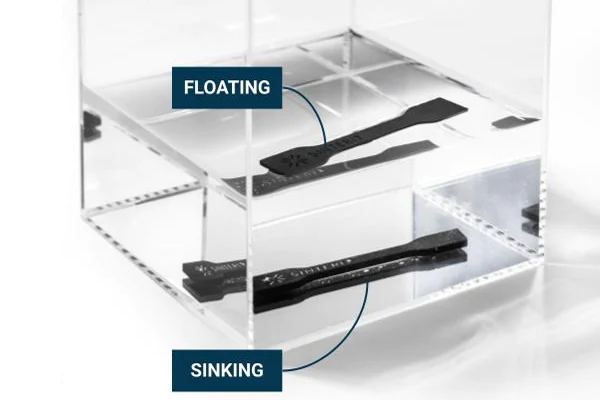

When layer sintering is finished, platforms are repositioning, and a dedicated mechanism replenishes the layer of powder from a supply chamber into the printing one and the process is repeated. In SLS technology no supports are needed as the unsintered powder, surrounding the printouts in the printing chamber, becomes a support itself.

The accuracy of SLS technology depends on the laser beam, its diameter and laser routing: perpendicular to the layer (H-BOT) or at an angle to the layer (Galvo). The accuracy depends also on the layer height. Every complex and complicated solid structure can be made, even with moving inner parts, if only the designed object makes it possible to get rid of the unsintered powder inside the model.

After the printing, excess powder can be removed simply by vacuuming or brushing. To get the best results, the printout can also be sandblasted. Selective laser sintering uses a wide range of materials like thermoplastics, elastomers and wax. Some industrial machines are operating on powdered metals (SLM, DMLS, LPBF) or ceramics.

When we compare the number of applications throughout SLS vs. SLA vs. FDM, selective laser sintering admittedly opens the list with the biggest number of potential applications. From functional, movable prototypes that can be tested in wind tunnels or pass other experimental testing, to final components printed in low or moderate volumes. Fit parts in assemblies, snap fits and hinges, rapid tooling, patterns, cores and moulds for casting and moulding, product concept models, medical and dental implants make up a list of uses. It is also used for education needs, both by researchers and academics to teach students.

Designing for SLS

Designers choose SLS because it gives them the freedom of form. Creating movable parts with complicated geometry is possible. As the supporting structures are not needed, it is also easier to prepare more detailed projects, with sharp edges, and thin walls. Layer thickness between 0.06 – 0.15 mm makes it very precise. The same as in the case of FDM and SLA, anisotropy in material properties makes the part weaker in vertical build direction.

Advantages of SLS

- No support structures needed.

- Movable parts with complicated inner geometry.

- Smooth surfaces – it is hard to notice the layer.

- Durable printouts.

- Powder is reusable after printing.

- Low to moderate material costs, while using the full working area.

- Desktop SLS 3D printers are inexpensive compared to industrial machines.

- Skilled labour is not required (only desktop SLS 3D printers).

Disadvantages of SLS

- Industrial machines are expensive.

- Long lead time.

- Cleaning of the machine must be done precisely when changing material to avoid contamination.

- Long printing time (for larger objects).

- For a powder management during post-processing a vacuum cleaner and compressed air is recommended as it can get dusty.

SLA vs SLS: detailed comparison

When comparing additive manufacturing technologies, SLA (Stereolithography) and SLS (Selective Laser Sintering) represent two advanced yet fundamentally different approaches to 3D printing — each optimized for distinct applications and material behaviors.

SLA uses a UV laser to cure liquid photopolymer resin layer by layer in a vat. This process enables exceptionally high-resolution prints with smooth surface finishes, making it well-suited for visual prototypes, dental models, jewelry masters, and precision engineering components. However, SLA requires support structures, which can limit the complexity of geometries and often necessitates manual post-processing to remove them.

SLS, in contrast, employs a high-powered laser to sinter powdered thermoplastics, such as PA12, PA11, or TPU, into fully solid objects. Since the surrounding unsintered powder supports each layer during the build, no support structures are needed, allowing for the creation of complex, interlocking, and nested geometries. The resulting parts are typically more robust and mechanically functional, making SLS prints ideal for low-volume production, functional prototyping, and end-use components in sectors such as automotive, aerospace, and medical devices.

From a performance standpoint, SLA vs SLS can be characterized by a trade-off between surface aesthetics and mechanical strength. SLA parts offer higher optical clarity and fine detail, but they’re generally more brittle and limited in thermal performance. SLS parts, while more granular in finish, exhibit superior impact resistance, load-bearing capability, and thermal stability — especially when produced with engineering-grade polymers.

Ultimately, the choice between SLA and SLS depends on application priorities. For intricate design visualization or ultra-fine detailing, SLA remains unmatched. For durability, geometric freedom, and scalability in production — SLS is the preferred industrial solution.

Comparison table: FDM vs SLA vs SLS – key differences at a glance

| Parameter | Fused Deposition Modeling | Stereolitography | Selective Laser Sintering |

|---|---|---|---|

| Abbreviation | FDM | SLA | SLS |

| Operation principle | Extrusion of melted filament | UV curing | Laser sintering |

| Material printed | Thermoplastic polymer in the form of string (filament) i.e. PLA, ABS | Resins/photocurable liquid materials | Powdered sinterable polymers (i.e polyamides, TPU, TPE) |

| Advantages | low costfast printing time | high print resolutionhigh process automatization | no support structure,quality, prototyping, movable parts |

| Disadvantages | need of support structuresthermal shrinkage of filament | narrow material varietyhigh maintenance costs | long printing time |

| Applications | fast prototypingeducationlow volume production | complex internal geometry prototypesdental models | education, functional prototypes, medical models, prototyping, moveable parts |

| Layer thickness | 0.1 – 0.3 mm | 0.05 – 0.15 mm | 0.060 – 0.15 mm |

| Printing without support structures | no | not always necessary | yes |

| Printing objects with movable parts | not always achievable (lower precision) | no | yes |

FAQ: FDM vs SLA vs SLS – 3D printing technologies compared

FDM (Fused Deposition Modeling) and SLA (Stereolithography) are two of the most common 3D printing technologies, but they differ significantly in how they work. FDM uses melted thermoplastic filament deposited layer by layer, while SLA uses a laser or projector to cure liquid resin. When comparing FDM vs SLA, SLA typically offers higher precision and better surface quality, while FDM is more affordable and easier to operate.![]()

Yes, SLA is generally more accurate than FDM. Stereolithography printers can achieve layer resolutions as fine as 0.05 mm, making them ideal for printing intricate details. In contrast, FDM typically operates with thicker layers (around 0.1–0.3 mm), which can result in more visible layer lines. For projects where surface smoothness and precision matter, SLA vs FDM clearly favors SLA.![]()

Stereolithography (SLA) offers several advantages over FDM. SLA provides a smoother surface finish, higher accuracy, and better detail resolution — especially important in dental models, jewelry, and prototypes with fine features. When comparing stereolithography vs FDM, SLA is often preferred in applications requiring visual presentation or tight tolerances. However, SLA materials and post-processing are more demanding.![]()

Between SLA and SLS, SLS is usually the better choice for functional prototypes. While SLA provides excellent surface detail, it produces brittle parts that are not ideal for mechanical testing. In the SLA vs SLS comparison, SLS offers superior strength, durability, and heat resistance, making it suitable for real-world applications. SLS also allows for moving parts and complex internal structures.![]()

FDM printers typically cannot match the print quality of SLA machines. SLA printing delivers higher resolution and smoother finishes due to its laser-based curing method. That said, modern FDM printers can produce acceptable results for prototypes where fine detail is not critical. In most comparisons of FDM vs SLA, FDM wins in cost, but SLA dominates in precision.![]()

SLS and SLA have different use cases due to their material and mechanical properties. SLA is often used for dental models, design prototypes, and castable parts that require detail. SLS, on the other hand, is preferred for durable, functional prototypes, snap fits, and low-volume end-use parts. The sls vs sla comparison clearly shows SLS’s advantage in strength and versatility.![]()

No, SLS 3D printing does not require support structures. Unlike FDM and SLA, where overhangs need scaffolding, SLS uses unsintered powder to support parts during printing. This allows for more freedom in design and enables printing of complex or nested geometries. In the fdm vs sla vs sls comparison, SLS is the only technology that truly prints without added supports.![]()

SLS is the best 3D printing technology for producing assemblies with moving parts. Since SLS doesn’t require support structures and works with high-performance powders like PA12, it enables the creation of interlocking mechanisms directly within a single print. SLA and FDM can struggle with accuracy or require post-assembly. If you’re comparing fdm vs sla vs sls for mechanical systems, SLS wins.![]()

Yes, FDM is generally the most cost-effective 3D printing technology. Both the printers and filament materials are inexpensive, and FDM setups require minimal post-processing. In the comparison of fdm vs sla, FDM offers the best value for educational, hobbyist, and basic prototyping needs. However, it compromises on precision and surface finish.![]()

SLA provides a finer surface finish and sharper details than SLS, making it ideal for visual models and detailed prototypes. SLS, however, produces stronger, more functional parts — even with complex geometries. In the sla vs sls comparison, SLA wins in aesthetics, while SLS excels in durability and application range. The choice depends on whether your priority is visual accuracy or mechanical performance.![]()

SLA uses a laser to cure liquid resin into solid parts with high detail and smooth surfaces, ideal for visual prototypes. SLS uses a laser to sinter powdered nylon, producing strong, functional parts without support structures — suitable for end-use applications.![]()

Yes, SLS is typically preferred for functional parts due to its superior mechanical properties, design freedom, and ability to print complex geometries without supports. SLA excels in surface quality and fine details but is more fragile.![]()

Choose SLA when high-resolution detail, smooth finishes, and visual appearance are the main priorities — for example, in dental models, prototypes, or jewelry. Use SLS when you need durability, mechanical performance, or production-ready parts.