Produkty

Wsparcie techniczne

As SLS 3D printing is getting more popular, we share our insights, tips, and tricks for you to use.

Case StudiesWith a four-figure installation worldwide of Sinterit's 3D printers, here you can find some of our client's stories.

SLS TechnologyGrasp the basic knowledge about SLS. Your journey starts here.

WebinarsCheck the latest webinars about our products, SLS technology and more

EbooksDownload special ebooks about SLS 3D printing technology

42.990,00 €*

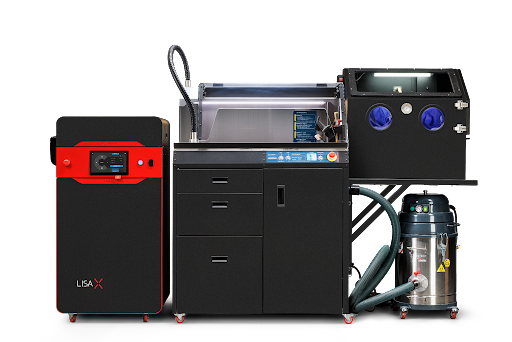

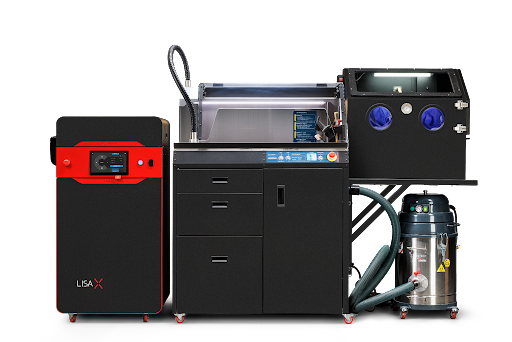

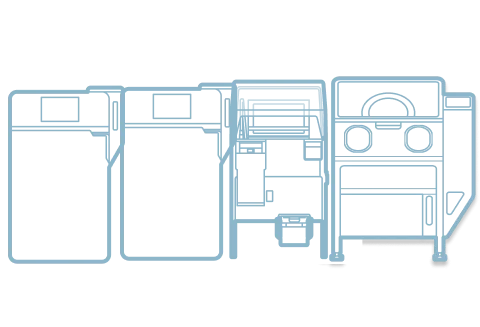

Lisa X Performance Set

ATEX Certified

The highest performance set on the market

67.295,69 €*

Fuse 1+ 30W Package

Formlabs Fuse 1+ 30W Package with comparable elements

Most SLS systems typically operate on a one printer = one material basis. At Sinterit, we’ve taken a different approach. Our system enables users to swiftly switch materials between jobs.

For example, if you want to print from TPU and PA12 materials, our Lisa X Performance Set with one printer will be adequate because you can easily change materials. However, if you want to print from two materials on the Fuse 1+ 30W, you need the Maximum Package with two printers.

42.990,00 €*

LISA X PERFORMANCE SET

ATEX Certified

Highest Performence set on the market.

105.726,74 €*

Fuse 1+ 30W Maximum Throughput Package

Fuse 1+ 30W Maximum Throughput Package with comparable elements

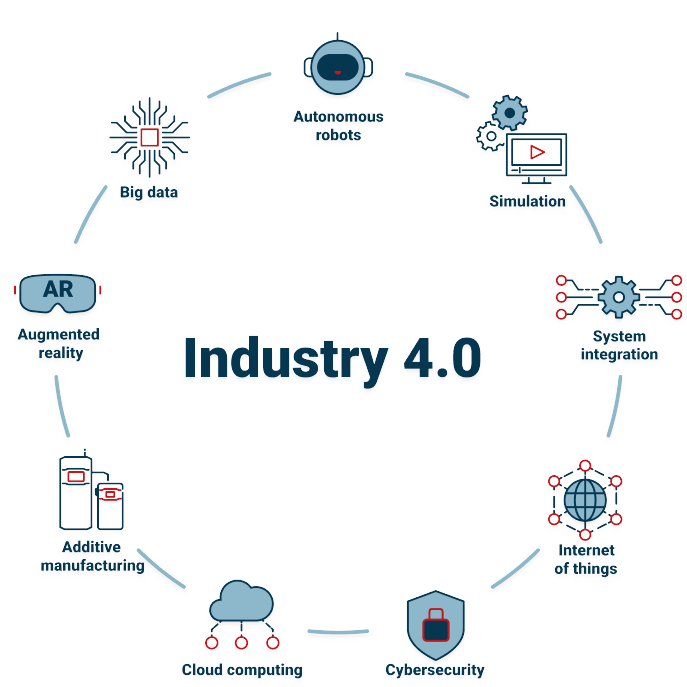

Industry 4.0 compatibility

Plug and print solution for convenience

ATEX safety certificate